Jaw chuck – Southbend South Bend EVS Toolroom SB1012 User Manual

Page 32

-30-

For Machines Mfg. Since 7/09

EVS Toolroom Lathes

O P E R A T I O N

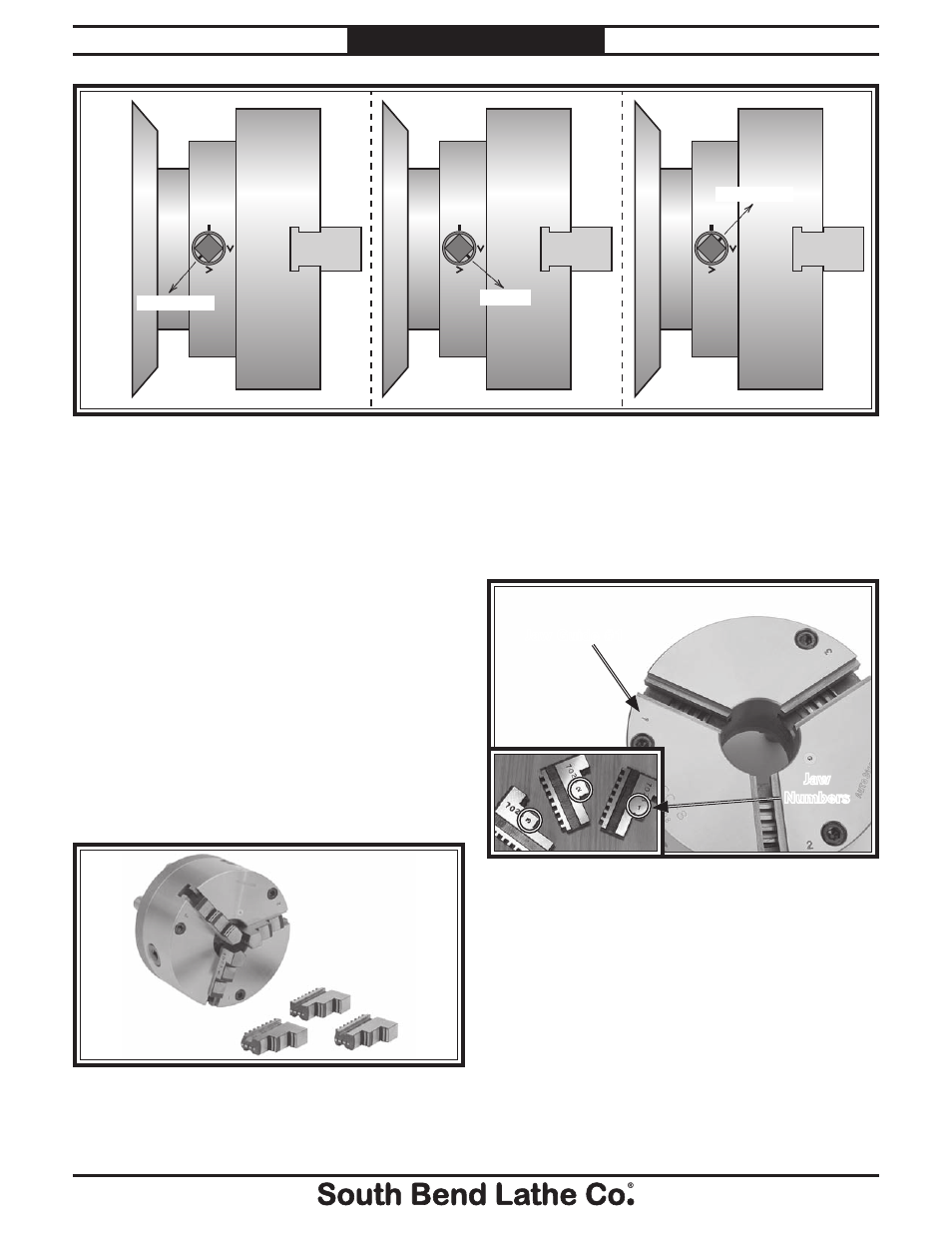

Figure 48. Correct camlock stud alignment.

Not Correct

Not Correct

Correct

3-Jaw Chuck

Refer to Chuck & Faceplate Mounting

instructions on Page 27 to mount the 3-jaw

chuck to the spindle.

The 3-jaw scroll-type chuck included with this

lathe features hardened steel jaws that center the

workpiece. When the operator opens or closes the

jaws with the chuck key, the jaws move in unison.

There are two sets of removable hardened steel

jaws included with the 3-jaw chuck—inside and

outside jaws. Use the correct jaws for the size

and configuration of the workpiece to hold it

firmly and securely on the chuck (see Figure

49). The outside of the jaws are used to hold the

workpiece from the outer diameter.

Figure 49. Chuck and jaw selection.

Numbered from 1–3, the jaws must be used in

the matching numbered jaw guides, as shown in

Figure 50.

Figure 50 Jaw guides and jaw numbers.

Jaw Guide #1

Jaw

Numbers

Note:

The chuck does not need to be removed

from the spindle to swap the jaws.