Troubleshooting, Pressure w asher tr oub leshooting guide – Shark SGP-3530E User Manual

Page 16

97-6132, 97-6151 • REV. 11/04

PRESSURE

W

ASHER

Tr

oub

leshooting Guide

16

97-6132, 97-6151 • REV. 11/04

17

PRESSURE

W

ASHER

Tr

oub

leshooting Guide

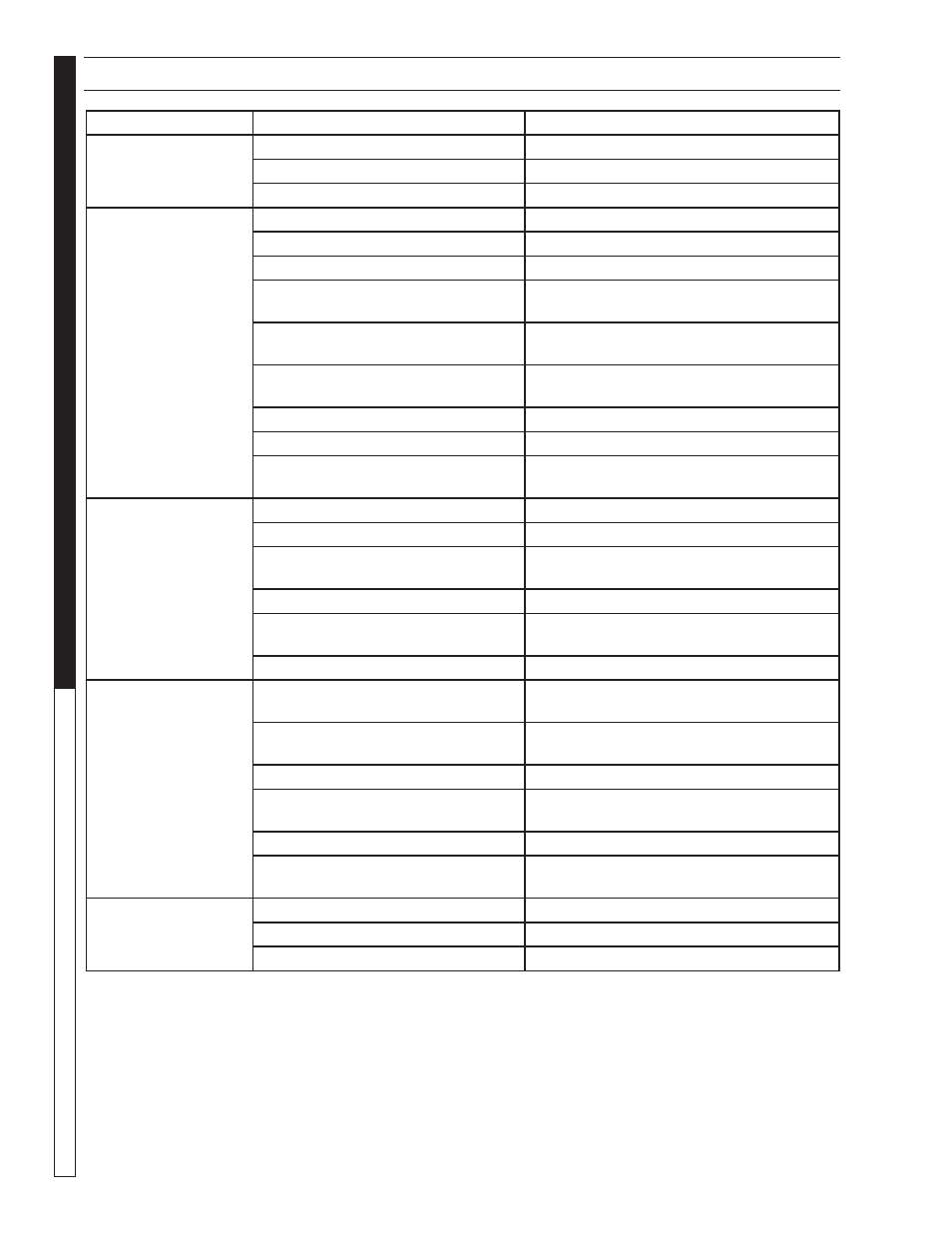

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

BURNER WILL NOT

LIGHT (continued

from previous page)

Burner nozzle is clogged

Clean as required.

Thermostat has malfunctioned

Test and replace if needed.

Fuel solenoid has malfunctioned

Test and replace if needed.

M

ACHINE SMOKES

Fuel is improper or water is in fuel

Drain tank and replace contaminated fuel.

Air adjustment is improper

Readjust air bands on burner assembly.

Fuel pressure is low

Adjust fuel pump pressure to specifications.

Burner nozzle is plugged or dirty

Replace nozzle. Check parts breakdown for

nozzle size.

Burner nozzle spray pattern is faulty

Replace nozzle. Check parts breakdown for

nozzle size.

Coil and burner assembly have heavy

accumulation of soot

Remove coils and burner assembly, clean

thoroughly. Call local dealer.

Electrode setting is misaligned

Realign electrodes to specifications.

Smoke stack has obstruction

Check for blockage or other foreign objects.

Engine RPM is low

Increase RPM to correct specs. See serial

plate.

LOW WATER

TEMPERATURE

Fuel is improper or has water in it

Replace with clean and proper fuel.

Fuel pressure is low

Increase fuel pressure.

Fuel pump is weak

Check fuel pump pressure. Replace pump if

needed.

Fuel filter is partially clogged

Replace as needed.

Soot buildup on coils is not allowing

heat transfer

Clean coils.

Burner nozzle is improper

Call your local dealer for proper nozzle.

WATER

TEMPERATURE

TOO HOT

Incoming water to machine is warm

or hot

Lower incoming water temperature.

Fuel pump pressure is too high

Call your local dealer for proper fuel pres-

sure.

Fuel pump is defective

Replace fuel pump.

Fuel nozzle is incorrect size

See parts breakdown or serial plate for

proper size.

Water supplied is insufficient

Check water GPM to machine.

Water flow is restricted

Check nozzle for obstruction and proper

size. Check serial plate for correct size.

PRESENCE OF

WATER IN OIL

Oil seal is worn

Check and replace if necessary.

Air humidity is high

Check and change oil twice as often.

Packing is worn or bad

Check and replace if necessary.