Troubleshooting, Pressure w asher, Pressure w asher tr oub leshooting guide – Shark SGP-3530E User Manual

Page 15

97-6132, 97-6151 • REV. 11/04

OPERA

TOR’S MANU

AL

PRESSURE

W

ASHER

14

97-6132, 97-6151 • REV. 11/04

15

PRESSURE

W

ASHER

Tr

oub

leshooting Guide

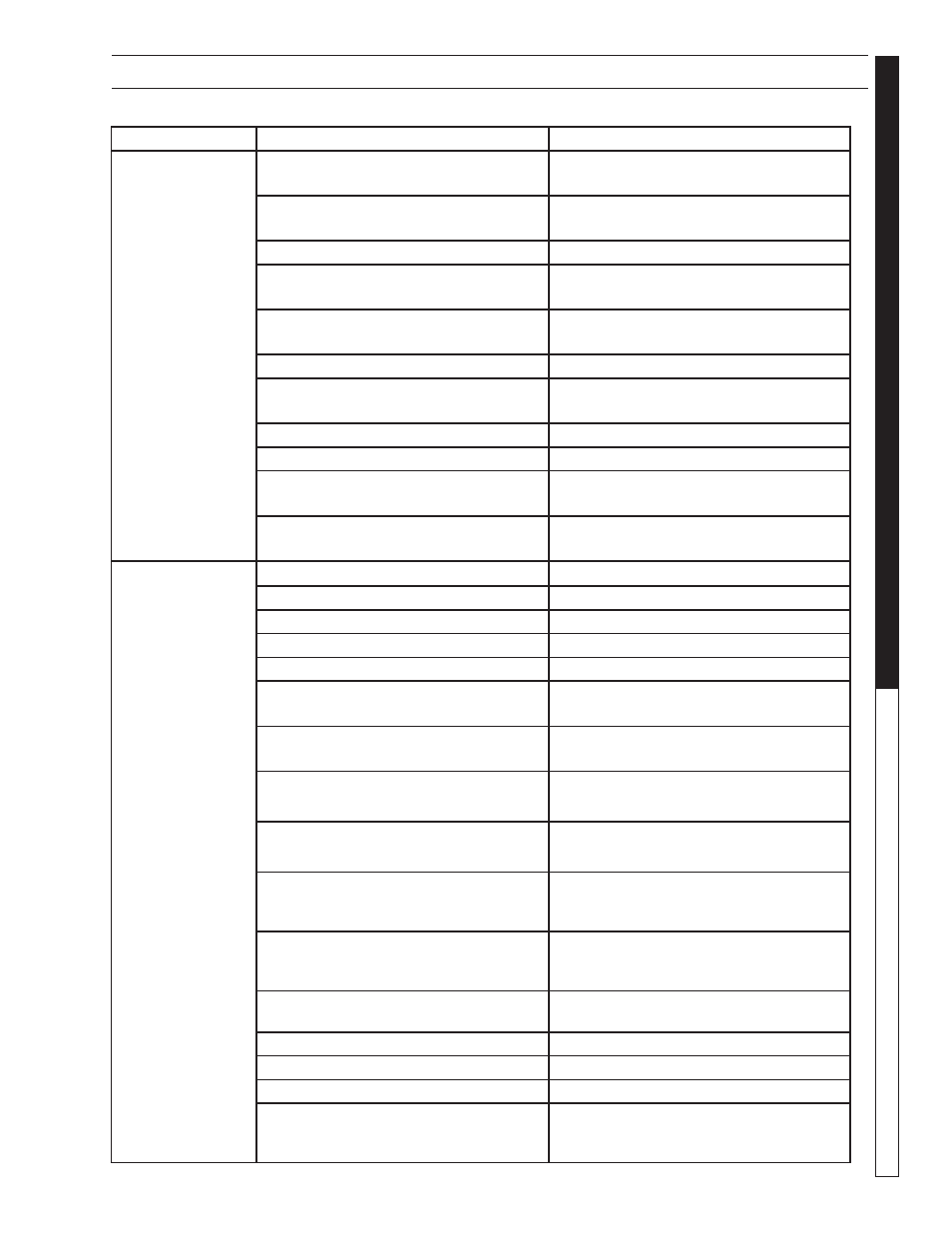

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

LOW OPERATING

PRESSURE

Water supply is insufficient

Use larger supply hose; clean filter at water

inlet.

Spray nozzle is old, worn or incorrect

Match the nozzle number to the machine

and/or replace with new nozzle.

Belt slips

Tighten or replace belt; use correct belt.

Plumbing or hose is leaking

Check plumbing system for leaks. Retape

leaks with teflon tape.

Unloader is faulty or misadjusted

Adjust unloader for proper pressure. Install

repair kit when necessary or replace.

Packing in pump is worn

Install new packing kit.

Discharge valve in pump or inlet is fouled

or dirty

Check inlet and discharge valve.

Discharge valve or inlet is worn

Replace with valve kit.

Spray nozzle has obstruction

Remove obstruction.

Steam pressure control valve is leaking

(where applicable)

Rebuild or replace as necessary.

Engine RPM is slow

Set engine speed at proper specifications /

see serial plate.

BURNER WILL

NOT LIGHT

There is little or no fuel

Fill tank with fuel.

Improper fuel or water in fuel

Drain fuel tank and fill with proper fuel.

Fuel line is clogged

Clean or replace fuel line.

Fuel filter is plugged

Replace fuel filter as needed.

Burner air bands are misadjusted

Readjust air bands for clean burn.

Little or no fuel pressure from fuel pump

Increase fuel pressure to specification and/

or replace fuel pump.

Burner transformer is faulty

Test transformer for proper arc between

contacts. Replace as needed.

Electrical wiring is disconnected or has

short in it

All wire contacts should be clean and tight

with no breaks in wire.

Flex coupling is slipping on fuel pump

shaft or burner motor shaft

Replace if needed.

ON-OFF switch is defective

Check for electrical current reaching burner

assembly with burner switch on. Replace

switce if needed.

Heavy sooting on coil and burner can

cause interruption of air flow and shorting

of electrodes

Clean as required.

Electrode setting is improper

Check and reset according to diagram in

manual.

25 amp circuit breaker tripped

Push in reset button.

Bridge rectifier defective

Test and replace.

12V DC relay defective

Test and replace.

Fuel is not reaching combustion chamber

Check fuel pump for proper flow. Check so-

lenoid flow switch on machines with spray

gun control for proper on-off flow control.