Siemens BACnet ATEC 125-5050 User Manual

Page 28

Chapter 3 – Point Database

28

Siemens Industry, Inc.

BACnet ATEC Owner's Manaul

125-5050, Rev. AA

4/20/2010

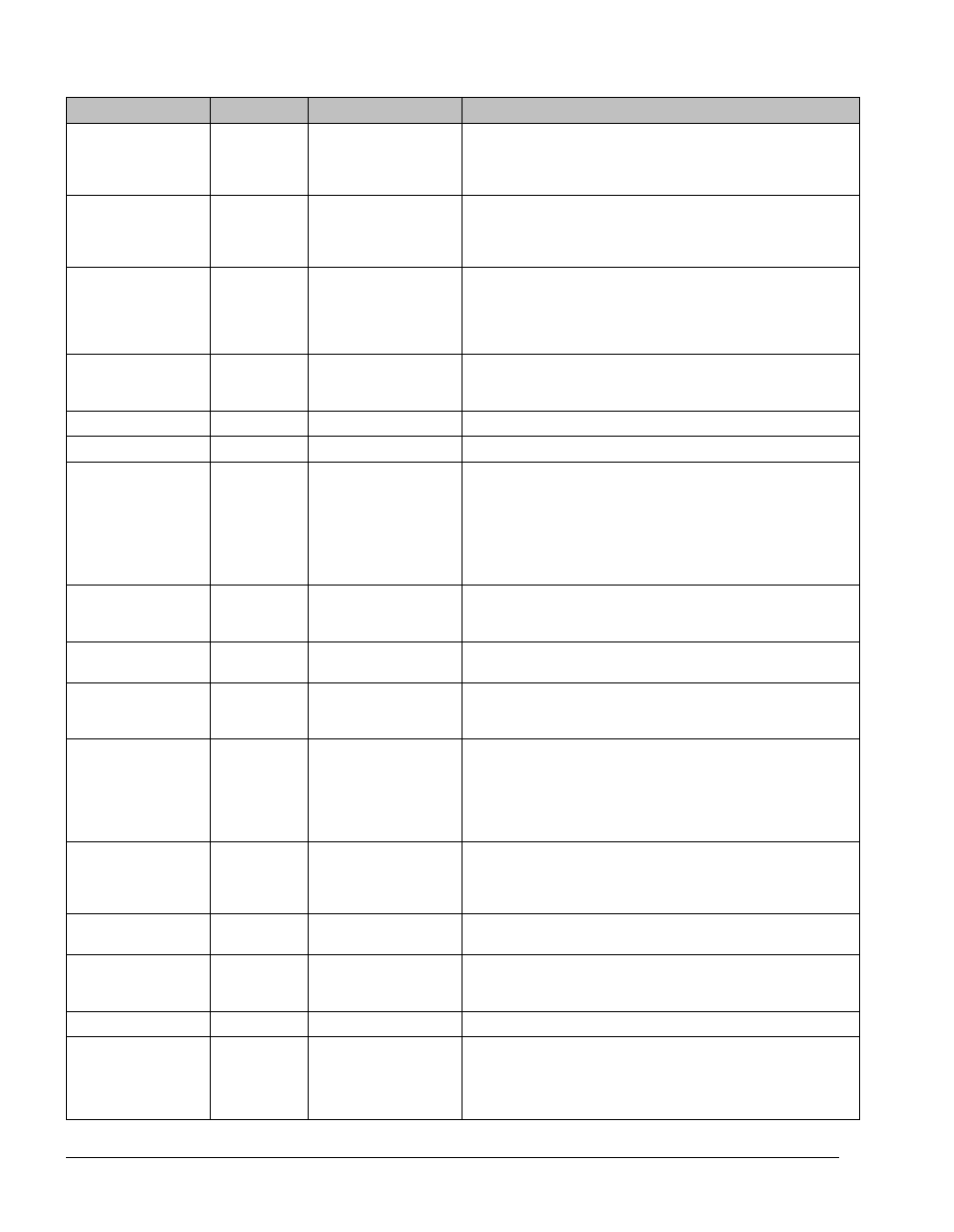

Descriptor

Address

1

Application

Description

FLOW

{75}

2

All

except 2597

Indicates the amount of air currently passing the air velocity

sensor. The value is calculated as a percentage based on

where the value of AIR VOLUME is in the range between 0

and CTL FLOW MAX.

CTL FLOW MIN

{76}

2

All

except 2597

The active minimum flow used as a limit for the flow control

loop. This value is the same as CLG FLOW MIN if the

controller is in cooling mode, or is the same as HTG FLOW

MIN if the controller is in heating mode, unless it is overridden.

CTL FLOW MAX

{77}

All

except 2597

The active maximum flow used as a limit for the flow control

loop. This value is the same as CLG FLOW MAX if the

controller is in cooling mode, or is the same as HTG FLOW

MAX if the controller is in heating mode unless, it is

overridden.

CTL TEMP

{78}

All

except 2597

The temperature used as input for the temperature control

loops. This value is the same as the value in ROOM TEMP

and RM TEMP OFFSET unless it is overridden.

CLG LOOPOUT

{79}

All

except 2597

The cooling temperature control loop output value in percent.

HTG LOOPOUT

{80}

All

except 2560, 2597 The heating temperature control loop output value in percent.

AVG HEAT OUT

{81}

2

2562, 2564, 2566

This point is used to determine what stages of electric heat

are used for a given loop output value. The ranges for the

value are determined by the number of stages used: 0 to 100

for 1 stage of electric heat, 0 to 200 for 2 stages of electric

heat, and 0 to 300 for 3 stages of electric heat.

With electric heat, this value is equal to: HTG LOOPOUT ×

STAGE COUNT.

STAGE MAX

82

2562, 2564, 2566

The value, in percent, which the heating loop must exceed for

the electric heat to be ON for the full duty cycle (STAGE

TIME).

STAGE FAN

83

2565, 2567

The valve must be opened greater than this value before the

fan will turn ON.

STAGE MIN

83

2562, 2564, 2566

The value, in percent, which the heating loop must go below

for the electric heat to be OFF for the full duty cycle (STAGE

TIME).

DMPR STATUS

{84}

2

2560, 2561, 2562,

2563

This point is used only when CAL MODULE set to YES. It

readjusts the damper position if the command value is not

equal to the actual position of the damper. CAL indicates that

the damper is operating normally. RECAL indicates that the

damper position was adjusted (recalibrated) by 25% because

the desired airflow was not obtainable under its current status.

SWITCH LIMIT

85

All

except

2560, 2561, 2597

The active temperature control loop output must be less than

this value to switch between cooling mode and heating mode.

Actual switchover depends on SWITCH DBAND being

exceeded and is subject to SWITCH TIME being expired.

SWITCH TIME

86

All

except

2560, 2561, 2597

The time, in minutes, before the heat/cool mode can change

over when the other parameters are appropriate.

STAGE COUNT

88

2562, 2564, 2566

The number of electric heating stages used by the application.

DOs associated with unused stages may be used as spare

DOs.

VALVE COUNT

88

2563

The number of heating valves available.

STAGE TIME

89

2562, 2564, 2566

The cycle time in minutes for the electric reheat stages. For

example, if there are three stages of electric heat and STAGE

TIME = 10 minutes, STAGE COUNT = 3, and AVG HEAT

OUT = 150% then, Stage 1 is ON for 10 minutes (100% of the

time), Stage 2 is ON for 5 minutes (50% of 10 minutes) and