Siemens BACnet ATEC 125-5050 User Manual

Page 27

Chapter 3 – Point Database

27

Siemens Industry, Inc.

BACnet ATEC Owner's Manaul

125-5050, Rev. AA

4/20/2010

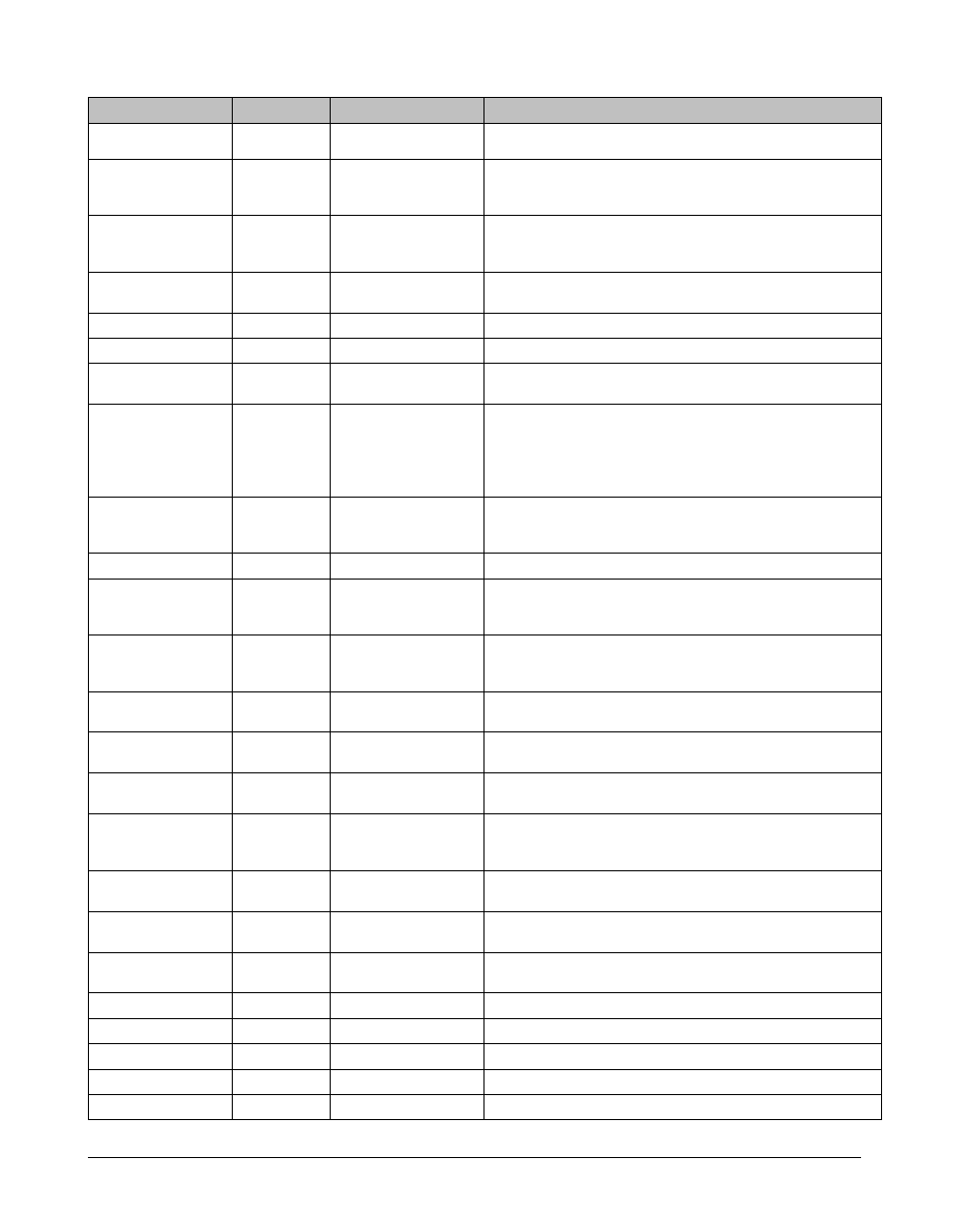

Descriptor

Address

1

Application

Description

travel (for use as an auxiliary slave point). This value is

calculated based on motor run time. See MTR2 TIMING.

VLV POS

{53}

2565

The current position of the valve in percent of full travel for

applications using a water valve. This value is calculated

based on motor run time.

VLV1 POS

{53}

2563

The current position of valve 1 in percent of full travel for

applications using a water valve. This value is calculated

based on motor run time.

MTR2 TIMING

55

All

except

2562, 2564, 2566

The time required for the Motor 2 actuator to travel from full

closed to the full open position.

DMPR ROT ANG

56

All

except 2597

The number of degrees the damper is free to travel.

DPR1 ROT ANG

56

2597

The number of degrees that damper 1 is free to travel.

DPR2 ROT ANG

57

2597

The number of degrees that damper 2, the hot duct damper, is

free to travel.

MTR SETUP

58

All

The configuration setup code for Motors 1 and 2. This enables

the motors individually and sets each motor to be either direct

or reverse acting.

Note: When a motor is enabled, its associated DOs are

enabled.

DO DIR.REV

59

All

The configuration setup code for DOs. Allows the DOs to be

direct or reverse acting (enabled equals energized or disabled

equals de-energized).

EHEAT FLOW

60

2562

The flow required before the electric heat will be enabled.

COOL TEMP

61

2561

The discharge air temperature where the controller will switch

from heating to cooling mode. Used only in applications with

SUPPLY TEMP.

HEAT TEMP

62

2561

The discharge air temperature where the controller will switch

from cooling to heating mode. Used only in applications with

SUPPLY TEMP.

CLG P GAIN

63

All

except 2597

The proportional gain value for the cooling temperature

control loop.

CLG l GAIN

64

All

except 2597

The integral gain value for the cooling temperature control

loop.

CLG D GAIN

65

All

except 2597

The derivative gain value for the cooling temperature control

loop.

CHK OUT

66

All

The procedure tests all of the necessary I/O and ensures the

controller has the ability to operate within the set airflow

range, between CLG FLOW MIN and CLG FLOW MAX.

HTG P GAIN

67

All

except

2560, 2597

The proportional gain value for the heating temperature

control loop.

HTG l GAIN

68

All

except 2560, 2597 The integral gain value for the heating temperature control

loop.

HTG D GAIN

69

All

except 2560, 2597 The derivative gain value for the heating temperature control

loop.

CHK STATUS

70

All

Displays the results of CHK OUT.

FLOW P GAIN

71

All

except 2597

The proportional gain value for the flow control loop.

FLOW l GAIN

72

All

except 2597

The integral gain value for the flow control loop.

FLOW D GAIN

73

All

except 2597

The derivative gain value for the flow control loop.

FLOW BIAS

74

All

except 2597

The biasing of the flow control loop.