Aligning cutting tool with spindle centerline – Southbend SB1049 User Manual

Page 49

For Machines Mfg. Since 5/11

13" Heavy 13

®

Gearhead Lathe

-47-

O P E R A T I O N

Aligning Cutting Tool with Spindle

Centerline

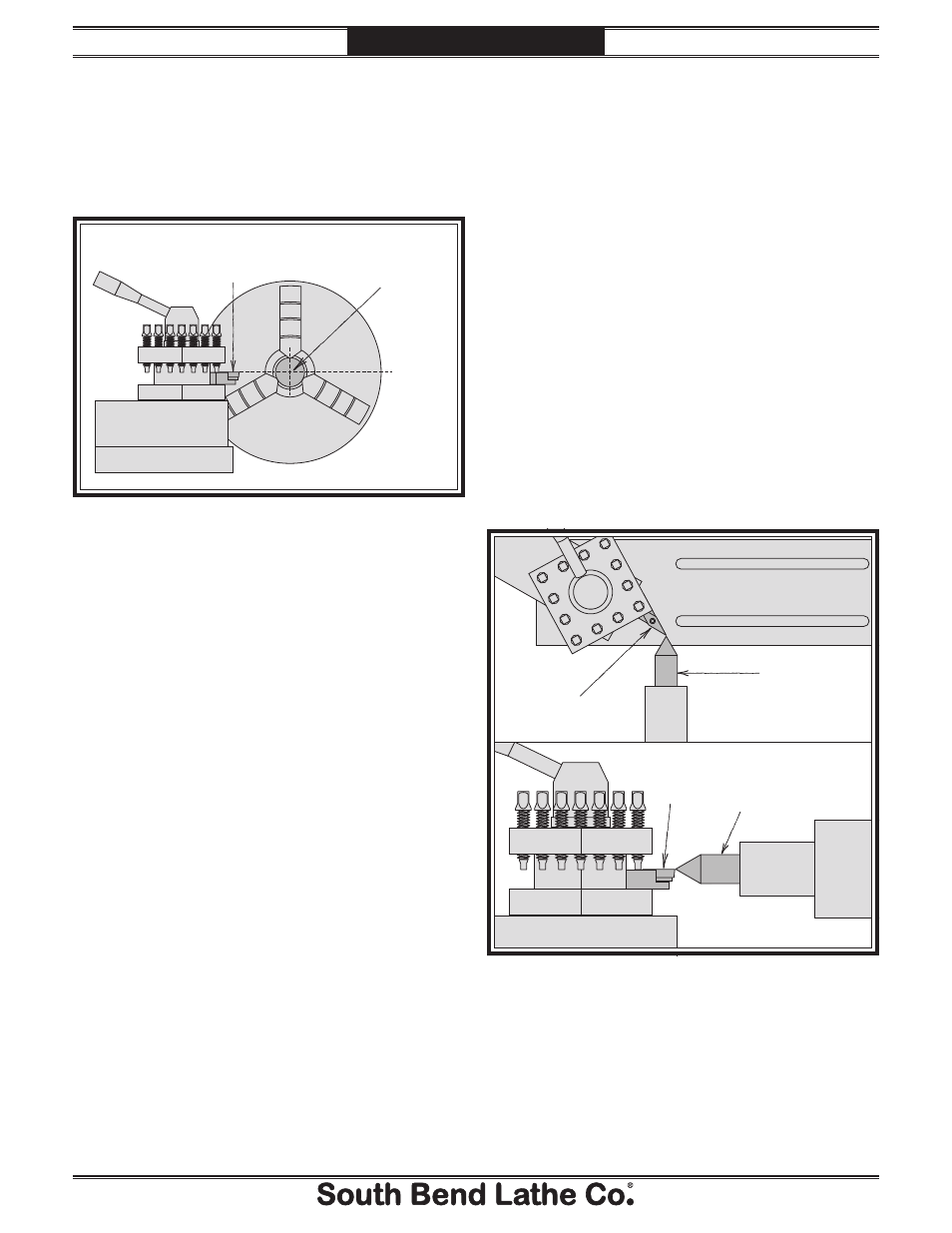

For most operations, the cutting tool tip should

be aligned with the spindle centerline, as

illustrated in Figure 60.

Figure 60. Cutting tool aligned with spindle centerline

(viewed from tailstock).

Cutting

Tool

Spindle

Center

Line

There are a number of ways to check and align

the cutting tool to the spindle centerline. If

necessary, you can raise the cutting tool by

placing steel shims underneath it. The shims

should be as long and as wide as the cutting tool

to properly support it.

Below are two common methods:

s

Align the tip of the cutting tool with a center

installed in the tailstock, as instructed on

the next page. For this to work, the tailstock

must be aligned to the spindle centerline

(refer to Aligning Tailstock To Spindle

Centerline on Page 40 for detailed

instructions).

s

-AKE

Tools Needed

Qty

Tool Post T-Wrench ............................................... 1

Steel Shims ............................................ As Needed

Cutting Tool ........................................................... 1

Fine Ruler .............................................................. 1

Tailstock Center .................................................... 1

To align the cutting tool with the tailstock

center:

1.

Mount the cutting tool in the tool post, then

secure the post so the tool faces the tailstock.

2.

Install a center in the tailstock, and position

the center tip near the cutting tool tip.

3.

Lock the tailstock and quill in place.

4.

Adjust the height of the cutting tool so

that the tool tip is aligned vertically and

horizontally with the center tip, as shown in

Figure 61.

Cutting

Tool

Tailstock

Center

(Top View)

Cutting

Tool

Tailstock

Center

(Side View)

Figure 61. Cutting tool tip aligned with tailstock

center.