Centers, Dead centers – Southbend SB1049 User Manual

Page 43

For Machines Mfg. Since 5/11

13" Heavy 13

®

Gearhead Lathe

-41-

O P E R A T I O N

Note:

If necessary in the following step, refer

to Offsetting Tailstock on Page 39 for

detailed instructions.

8.

Use calipers to measure both ends of the

workpiece.

— If the test stock is thicker at the tailstock

end, move the tailstock toward the front of

the lathe

1

⁄

2

the distance of the amount of

taper (see Figure 46).

9.

Repeat

Steps 6–8 until the desired accuracy

is achieved.

Move the tailstock toward

the front of the lathe ½ the

distance of the taper.

Looking down from above.

Figure 46. Adjust tailstock toward the operator.

— If the test stock is thinner at the tailstock

end, move the tailstock toward the back of

the lathe

1

⁄

2

the distance of the amount of

taper (see Figure 47).

Move tailstock toward the

back of the lathe ½ the

distance of the taper.

Looking down from above.

Figure 47. Adjust tailstock away from the operator.

Centers

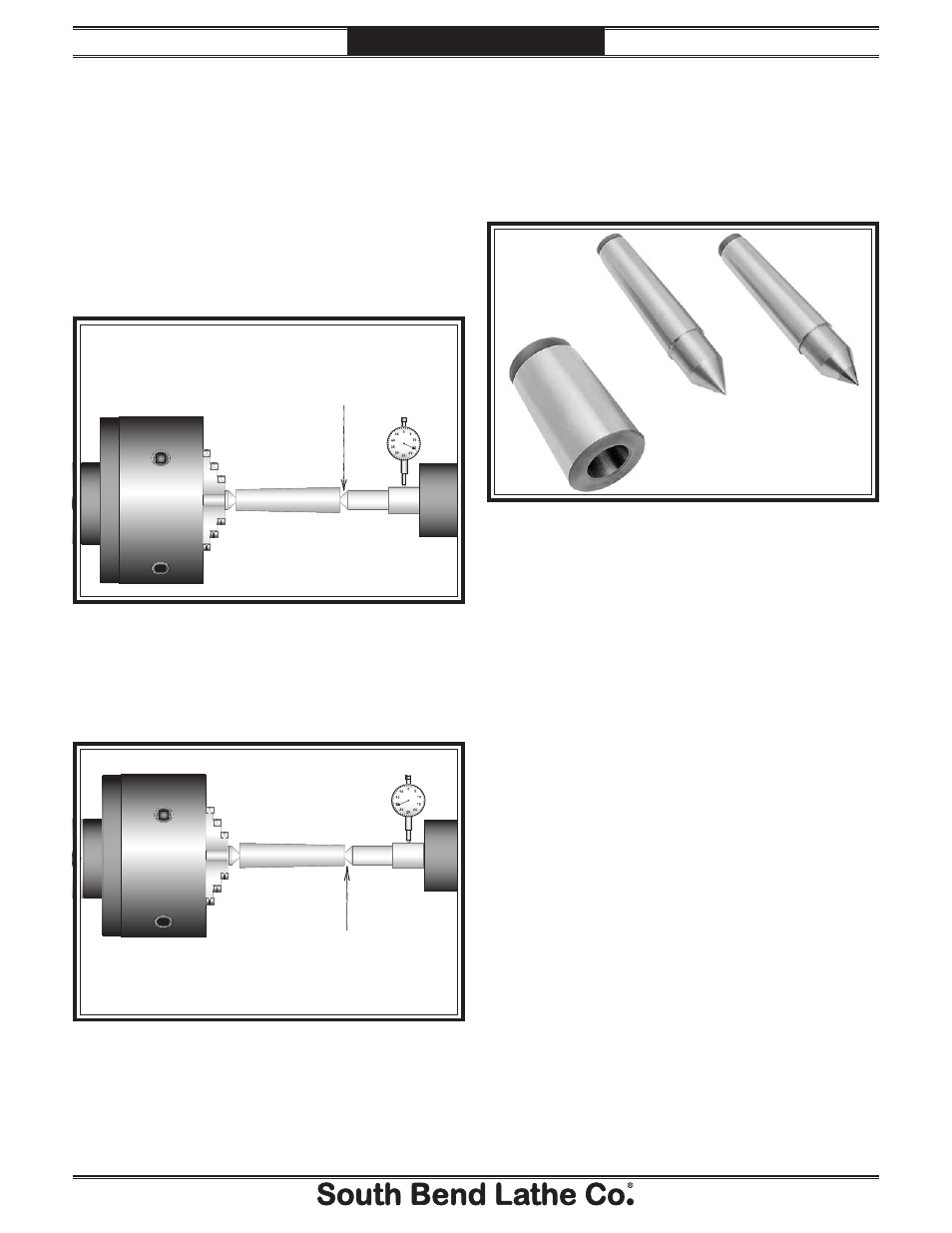

Figure 48 shows the MT#5 dead centers

included with the lathe. In addition, an MT#7–

MT#5 tapered spindle sleeve is included for

mounting centers in the spindle.

Dead Centers

A dead center is a one-piece center that does not

rotate with the workpiece and is used to support

long, slender workpieces

Use the dead center in the spindle for operations

where the workpiece rotates with the center and

does not generate friction.

The carbide-tipped dead center can better

withstand the effects of friction and is best

used in the tailstock where the workpiece will

rotate against it. The tip of the center must be

generously lubricated during the operation to

avoid premature wear and maximize smooth

operation. Using low spindle speeds will also

reduce the heat and wear from friction.

Figure 48. Adapter sleeve and dead centers.

Adapter

Sleeve

Carbide Tipped

Dead Center

Dead

Center