Lubrication, Headstock – Southbend Turn-nado Gearhead w/DRO SB1046PF User Manual

Page 70

-68-

For Machines Mfg. Since 3/11

Turn-Nado

®

Gearhead Lathes

M A I N T E N A N C E

Lubrication

Changing Headstock Oil

The headstock oil must be changed after the

break-in period and then annually (or every six

months with heavy service or extreme working

conditions).

Since this lathe uses a base-mounted oil tank,

removing the drain plug and using a drain pan

is not a convenient option when changing the oil.

Alternately, we recommend using a remote oil

pump with a suction hose that can be inserted

through the filler spout to the bottom of the oil

tank.

If a remote oil pump system is not available,

use the headstock oil pump for this purpose, as

instructed below.

Items Needed:

Qty

5-Gallon Waste Oil Bucket with Lid ....................1

Adjustable Wrench ................................................1

Hex Wrench 4mm .................................................1

Mineral Spirits ...................................... As Needed

Shop Rags .............................................. As Needed

Low-Profile Catch Pan ..........................................1

Pipe Tape or Sealant ............................. As Needed

To drain the headstock oil tank:

1. DISCONNECT LATHE FROM POWER!

2. Remove the end gear cover and the side

access panel from the left stand.

3. Disconnect the headstock oil supply hose see

(Figure 97) from the headstock and point it

into the waste bucket.

Headstock

The headstock is supplied with oil from the oil

tank in the base of the left stand.

When the spindle motor is started, a belt-driven

oil pump circulates oil across the headstock gears

before spindle rotation is started.

Checking & Adding Oil

Oil Type...Mobil DTE Light or ISO 32 Equivalent

Oil Amount .......................................... 15.9 Quarts

Check/Add Frequency ....................................Daily

Change Frequency ...................................Annually

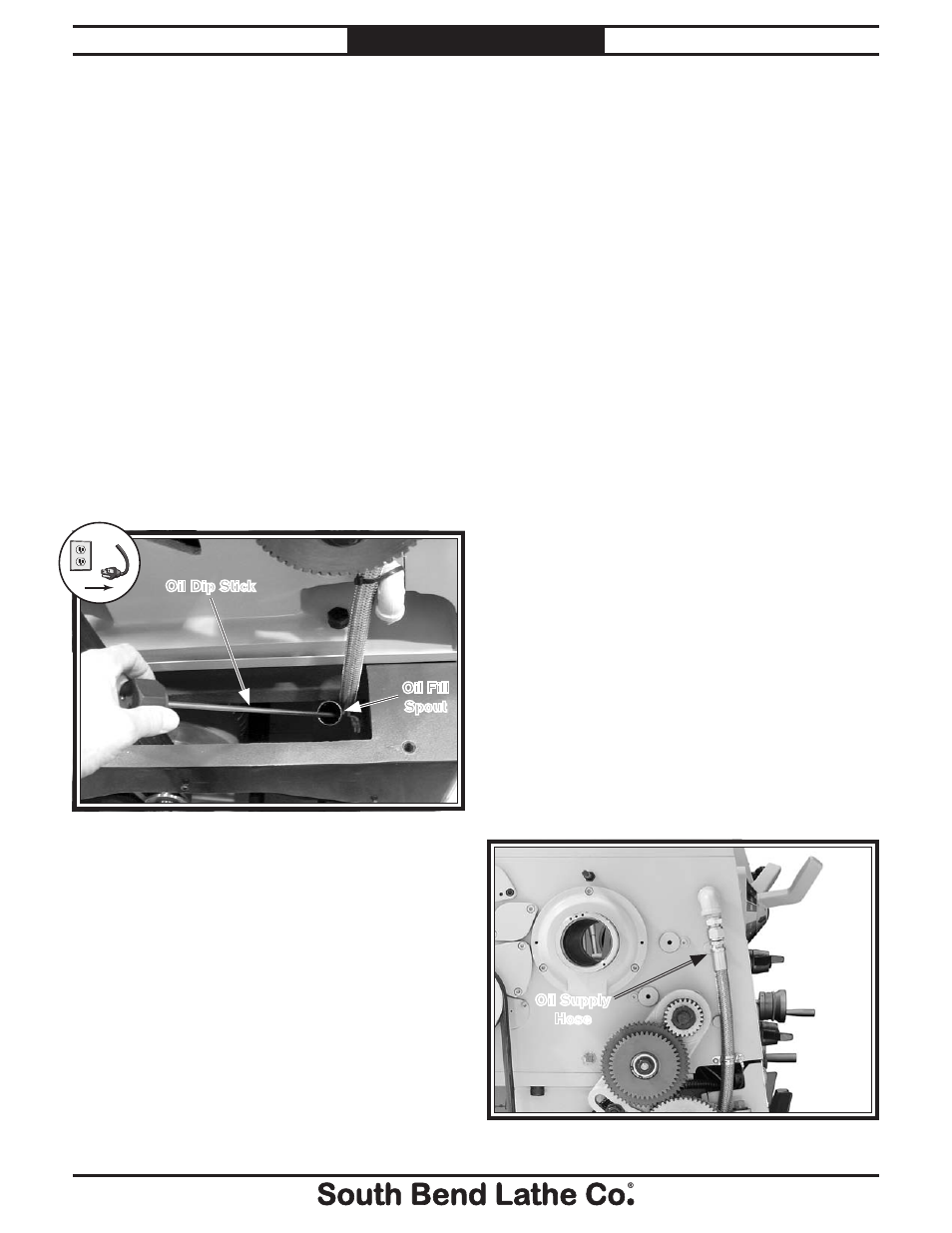

Remove the end gear cover and the side access

panel from the left stand, then unthread the oil

fill cap to check the oil level on the dip stick (see

Figure 29).

If the oil on the dip stick is less than 3" from the

tip of the stick, add oil.

Figure 96. Checking headstock oil tank level.

Oil Dip Stick

Oil Fill

Spout

!

Figure 97. Headstock oil supply hose.

Oil Supply

Hose