Grounding requirements – Southbend Turn-nado Gearhead w/DRO SB1046PF User Manual

Page 25

For Machines Mfg. Since 3/11

Turn-Nado

®

Gearhead Lathes

-23-

P R E P A R A T I O N

Grounding Requirements

This machine must be grounded! In the event

of certain types of malfunctions or breakdowns,

grounding provides a path of least resistance

for electric current in order to reduce the risk of

electric shock.

Improper connection of the equipment-grounding

wire can result in a risk of electric shock. The

wire with green insulation (with or without

yellow stripes) is the equipment-grounding

wire. If repair or replacement of the power cord

is necessary, do not connect the equipment-

grounding wire to a live (current carrying)

terminal.

Check with a qualified electrician or service

personnel if you do not understand these

grounding requirements, or if you are in doubt

about whether the machine is properly grounded.

If you ever notice that a cord is damaged or

worn, disconnect it from power, and immediately

replace it with a new one.

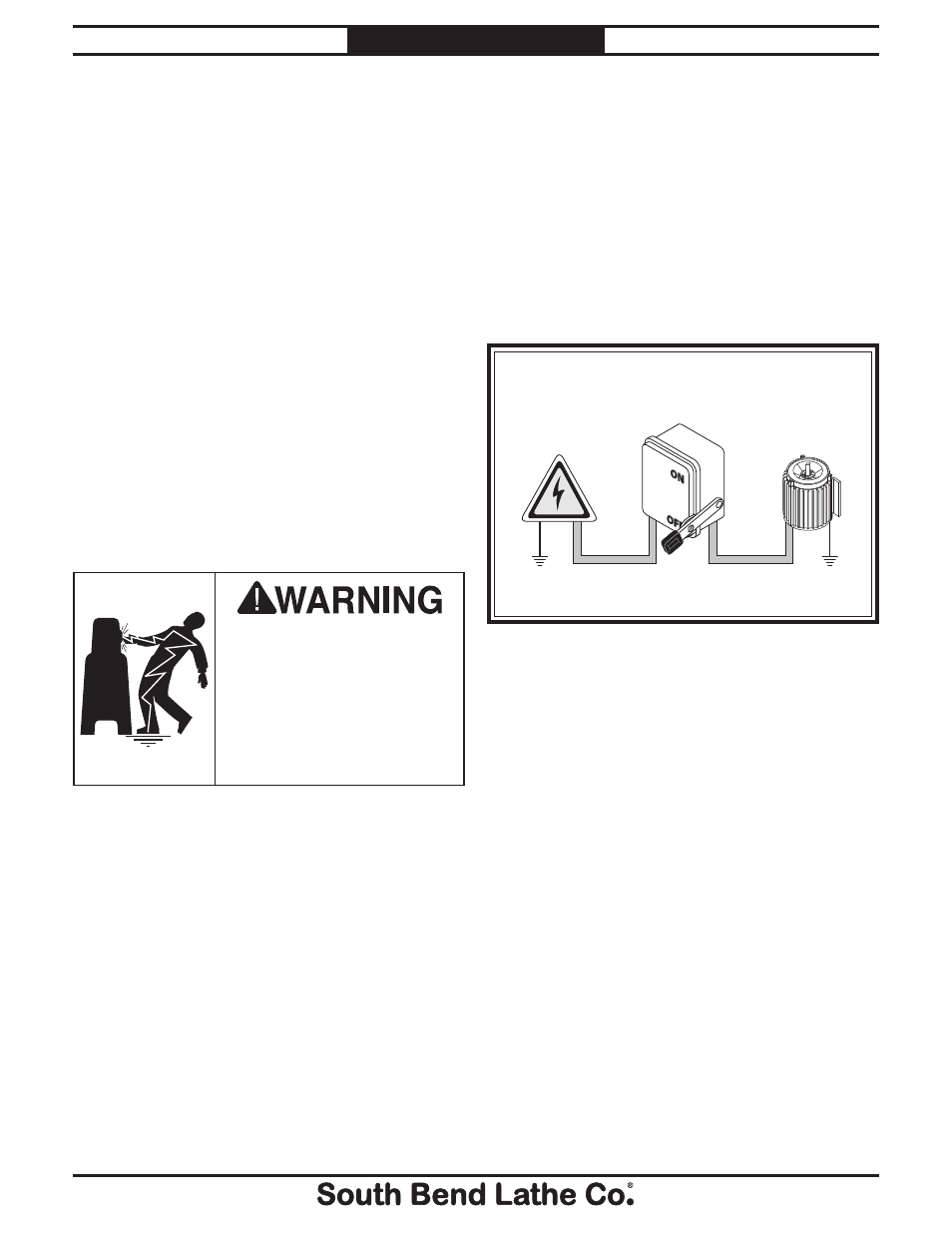

440V Operation

As specified in the Circuit Requirements

section on the previous page, these machines

must be hardwired to the power source, using a

locking switch (see Figure 10).

These machines must also be connected to a

grounded metal permanent wiring system; or to a

system with an equipment-grounding conductor.

Due to the complexity and high voltage involved,

this type of installation MUST be done by an

electrician or qualified service personnel.

Figure 10. Typical hardwire setup with a locking

disconnect switch.

Power Source

LOCKING

DISCONNECT SWITCH

Machine

Conduit

Ground

Ground

Conduit

Electrocution or fire may

occur if machine is not

correctly grounded and

attached to the power

supply. Use an electrician or

qualified service personnel

to ensure a safe power

connection.