Sentry, Warning – Slant/Fin SENTRY SX-210 User Manual

Page 12

3. Water lines: slightest leaks should be corrected.

4. Low water cutoff, for operation (see instructions fur-

nished with unit).

2. WATER LEVEL CHECK DURING HEATING SEASON

A. Check water pressure regularly and add water slowly to

system when needed. If much water is added, venting

may be necessary.

B. Regular loss of water from water boiler system may indi-

cate either a system leak, or a faulty air control system,

or a faulty automatic fill valve.

3. ANNUAL INSPECTION AND CLEANING

A. It is important that this boiler be inspected by a compe-

tent serviceperson to help insure safe and reliable oper-

ation.

B. Check for gas leaks from valve and gas piping to burners

and pilot. If leaks are found, repair or replace as required.

C. This inspection should include:

1. Controls check. See “Safety Check for Control

System” (No. 4) below.

2. Recheck of input gas rate to burners. See "Initial

Start" paragraph in "Operating instructions" section.

3. Re-adjusting for best flame characteristics of main

flame and pilot(s).

See

"Initial

Start"

paragraph

in

"Operating

Instructions" section and see "Burner Adjustment"

section.

4. Burner and boiler flue passage cleanliness:

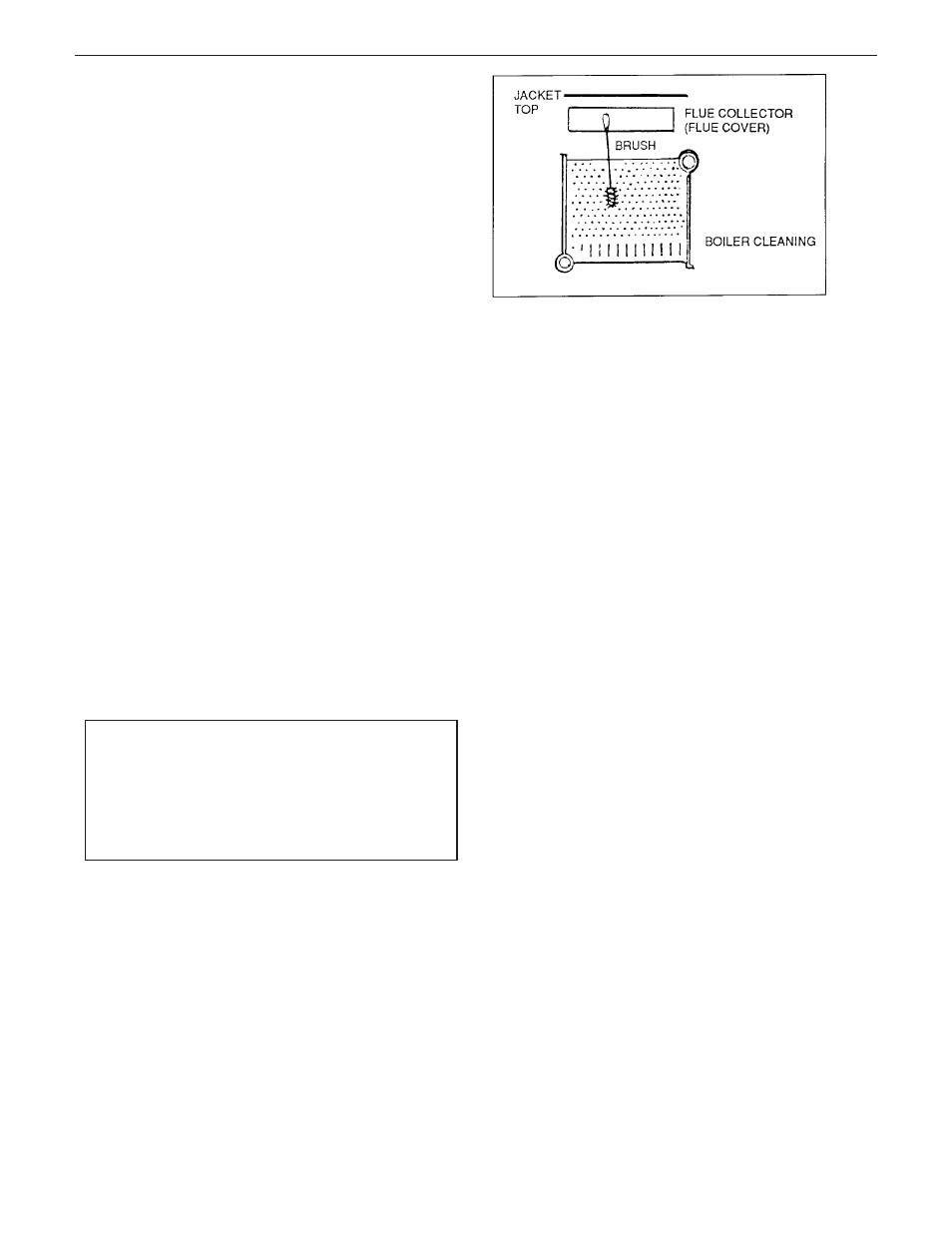

BURNER AND FLUE CLEANING (see figure 17). It is

suggested that paper be placed on burners to collect

any foreign material when cleaning flues.

5. Remove jacket top and flue cover.

6. Use wire brush to clean flueways.

7. Replace flue cover and re-seal with furnace cement.

Replace jacket top. Remove and dispose of paper

and accumulated material.

8. If burner surfaces are not clean, or if uneven flame

indicates plugged burner ports, remove and clean

burners.

NOTE-TO REMOVE BURNERS:

1. Disconnect pilot at pilot mount, or disconnect pilot gas

line at gas valve, before removing burners next to pilot.

2. Lift burner and remove burner from orifice.

3. Clean and replace burners* and pilot. Adjust burners as

described on page 10.

* To clean burners run a clean flue brush up the tube until all foreign

matter is removed.

4. SAFETY CHECK FOR CONTROL SYSTEM

A. High limit control test: Set thermostat high enough for

boiler water temperature to reach high limit control set-

ting. When this temperature is reached, the high limit

switch should open, and the main gas valve should close

automatically. If the high limit does not operate to close

the main gas valve, the valve, the high limit or the wiring

is faulty. Repair or replace immediately.

B. Gas valve safety shutdown test:

1. For boiler equipped with continuous burning pilot, with

main burners firing, disconnect the thermocouple

from the gas valve. The gas valve should immediate-

ly shut off the main burners and the pilot.

2. For boilers equipped with Honeywell S8600 intermit-

tent pilot system, with main burners firing, disconnect

the ignition cable from the S8600 IGNITOR BOX. The

gas valve should shut off the main burners.

If the gas valve fails to shut down main burners when

the test in 1 or 2 is performed, replace the gas valve.

C. Check for gas leaks from valve and gas piping to burners

and pilot. If leaks are found, repair or replace as required.

5. PROVIDING PROTECTION FROM FREEZING

A. Anti-freeze is sometimes used in hydronic heating sys-

tems to protect against freeze-up in the event of power

failure or control shutdown when the building is unoccu-

pied. It should be recognized that unless the building is

kept above freezing temperature by some means, the

plumbing system is not protected.

PROPYLENE GLYCOL is used in the quick-freeze food

industry; it is practically non-toxic. Its use may be permit-

ted when tankless heaters are used. When anti-freeze

must be used, inhibited propylene glycol is recommend-

ed. Useful information on the characteristics, mixing

proportions, etc. of glycol in heating systems is given in

Technical Topics No. 2A, available from the Hydronics

Institute 34 Russo Place, Berkeley Heights, NJ 07922.

Consult glycol manufacturers for sources of propylene

glycol. DO NOT use ethylene glycol because it is toxic.

B. Water Treatment:

A good water treatment program will not only extend the

useful life of this boiler but it will also save much of the

time and expense of repairs made necessary by pre-

ventable occurrences.

A reputable water treatment company should be consult-

ed to evaluate and determine the best overall treatment

program for your boiler equipment.

6. KEEP THE BOILER AREA CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE, AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

Figure 17.

12

Sentry

WARNING:

The ceramic combustion chamber in the burner box

contains crystalline silica.

Wear proper dust mask and gloves when servicing

combustion chamber or burners.

Crystalline Silica has been identified as a carcinogen or

possibly carcinogenic to humans.