Slant/Fin VHS-180 User Manual

Page 5

V

ICTORY

II

VHS Models

CATEGORY II AND III VENTING

1. Vent Material

A) The vent system for horizontal or vertical venting

(Category II and III) must be UL listed single wall 3"

diameter AL29-4C

▲

stainless steel material. The follow-

ing manufacturers’ systems are approved for use within

a specified minimum and maximum equivalent vent

length for each model. Proper adapter must be used as

a connector between Victory II boilers flue collar and

venting system as shown below:

Heat-Fab Part Numbers for various items of vent system are

listed in Slant/Fin Part List, Publication No. VHS-10PL.

B) When joining the various components of the above

listed vent systems, the manufacturers’ instructions

should be closely followed to insure proper sealing.

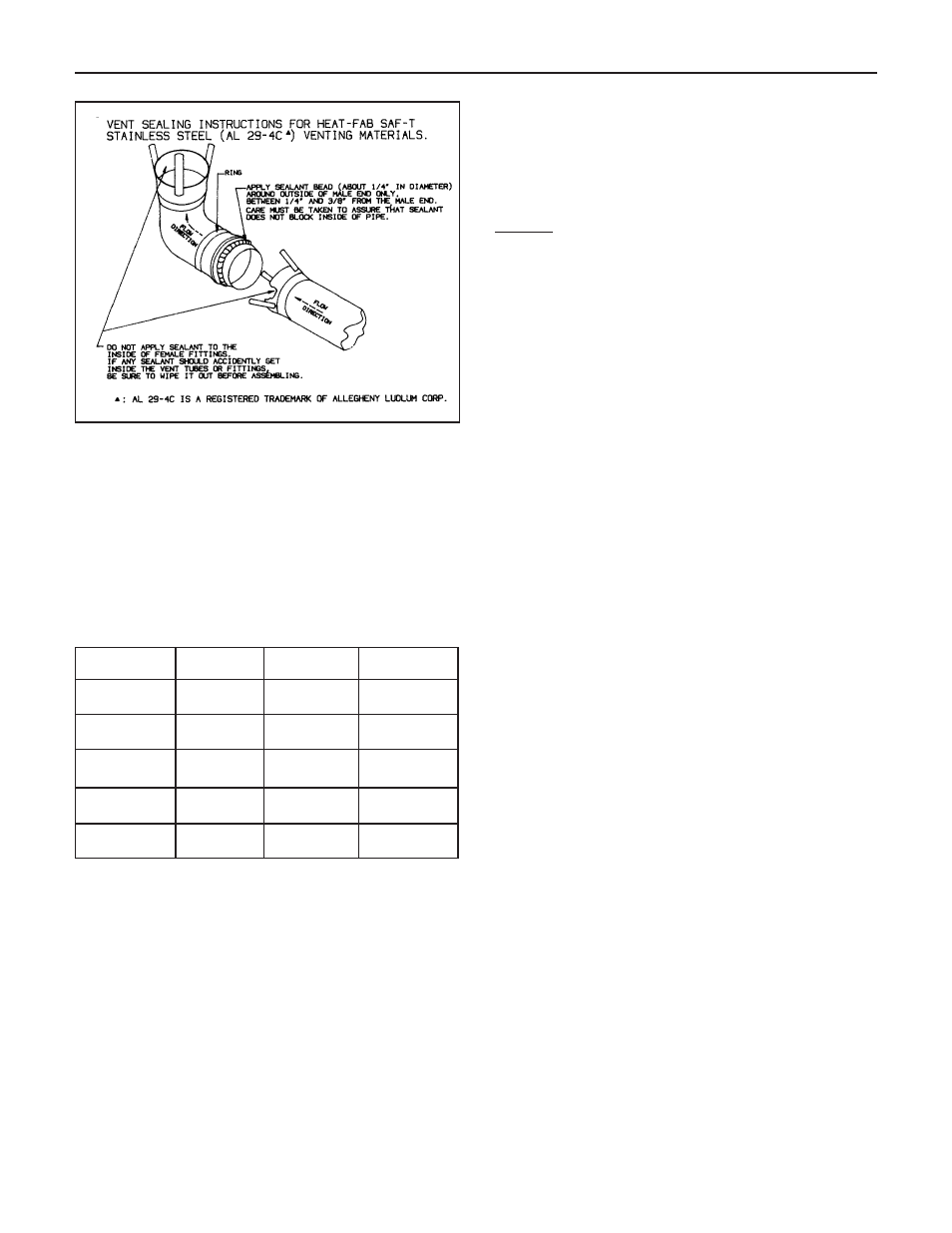

C) Use sealant specified by vent system manufacturer

for sealing of pipe and fittings. See Figure 4 for

proper application of vent pipe sealing for Safe-T vent

system by Heat-Fab. Inc.

D) All vent connections must be liquid and pressure tight

E) Flue vent system CANNOT be cut to length. Consult

manufacturer’s instructions. For Heat-Fab system, use

slip joint connector to adjust pipe lengths dimensions.

F) DO NOT use plastic or galvanized flue pipe.

2. Flue Length Restriction

Maximum and minimum equivalent flue length for different

systems are given in the tables on page 6. Equivalent flue

length is sum of straight flue lengths and equivalent

length of elbows. The vent termination is in addition to the

allowed equivalent lengths.

Example: Boiler Model VHS-180 is to be installed at sea

level with 2 elbows using Heat-Fab vent system. Maximum

straight run would be: 40 - 2 x 3 = 34ft. If same boiler is to

be installed in Colorado Springs (5,980 ft. altitude), the maxi-

mum straight run would be: 20 - 2 x 3 = 14 ft.

3. Installation

A. Horizontal Venting:

Figures 5 and 6 show typical horizontal venting. For

combustible wall passage of vent piping a U.L. listed

thimble must be used. See Figures 5 and 6 for wall

thimble Part Numbers and more information.

B. Vertical Venting:

Figure 7 shows typical vertical venting. A fire stop is

required for each ceiling and floor penetration. An

existing chimney (see Figure 8) may be used as a

chase for vertical venting. Other appliances CANNOT

be vented into the same chimney or vent pipe within

the chimney.

For both, horizontal and vertical venting, the following

points MUST be followed:

A. All Victory II boilers are equipped with a built-in con-

densation drain and trap. The trap loop must be filled

with water. DO NOT operate the boiler without filling

the trap with water to prevent flue gas discharge into

space. The drain should extend to a floor drain or to a

container which may require emptying periodically.

B. The horizontal vent pipe must be sloped upward from

the boiler at a pitch of at least 1/4" per 1 foot of run, so

that the condensate from the vent system runs to the

drain trap.

C. The horizontal vent pipes must be supported with pipe

straps at intervals no greater than indicated by vent

pipe manufacturer’s instructions. The vertical portion

vent pipe also must be supported per manufacturer’s

instructions.

D. Minimum clearances of vent pipes from combustible

constructions must be maintained (see Page 3).

E. Common venting with other appliances or another Vic-

tory

II boiler is NOT allowed.

F. The vent piping must terminate with a screened elbow

or tee. See Figures 5 and 6 for horizontal and 7 and 8

for vertical termination information. A cap termination

may be used for vertical venting.

G. See Appendix A for vent system location and conden-

sation drain requirements.

H. For roof passage of vent piping a U.L. listed roof flash-

ing must be used.

Figure 4. Vent Sealing Instructions

(Consult vent manufacturer’s instructions.)

5

▲

: AL 29-4C is a registered trademark of Allegheny Ludlum Corp.

Manufacturer Type/System Adapter Part

Sealant

No.

Heat-Fab. Inc.

Saf-T Vent

Not Required

RTV 106 or Dow

Corning 732

Heat-Fab. Inc.

Saf-T Vent

Not Required

Not Required

EZ Seal

ProTech System,

FasNSeal

FSA-SLB-3

Not Required

Inc.

Flex-L StaR-34

SRASFA3

GE-1S806

International, Inc.

Z-Flex, Inc.

Z-Vent

O2SVSSLA2

GE, RTV 106