Notice, Belt tension adjustments, Adjustments – Woodstock SHOP FOX W1667 User Manual

Page 15

-13-

The drill press drive belt lasts a long time;

however, during its life the belt may stretch

slightly, which can cause the pulleys to slip

under a load. You will then need to adjust the

drive belt tension.

To adjust the drive belt tension, do these

steps:

1. UNPLUG THE DRILL PRESS!

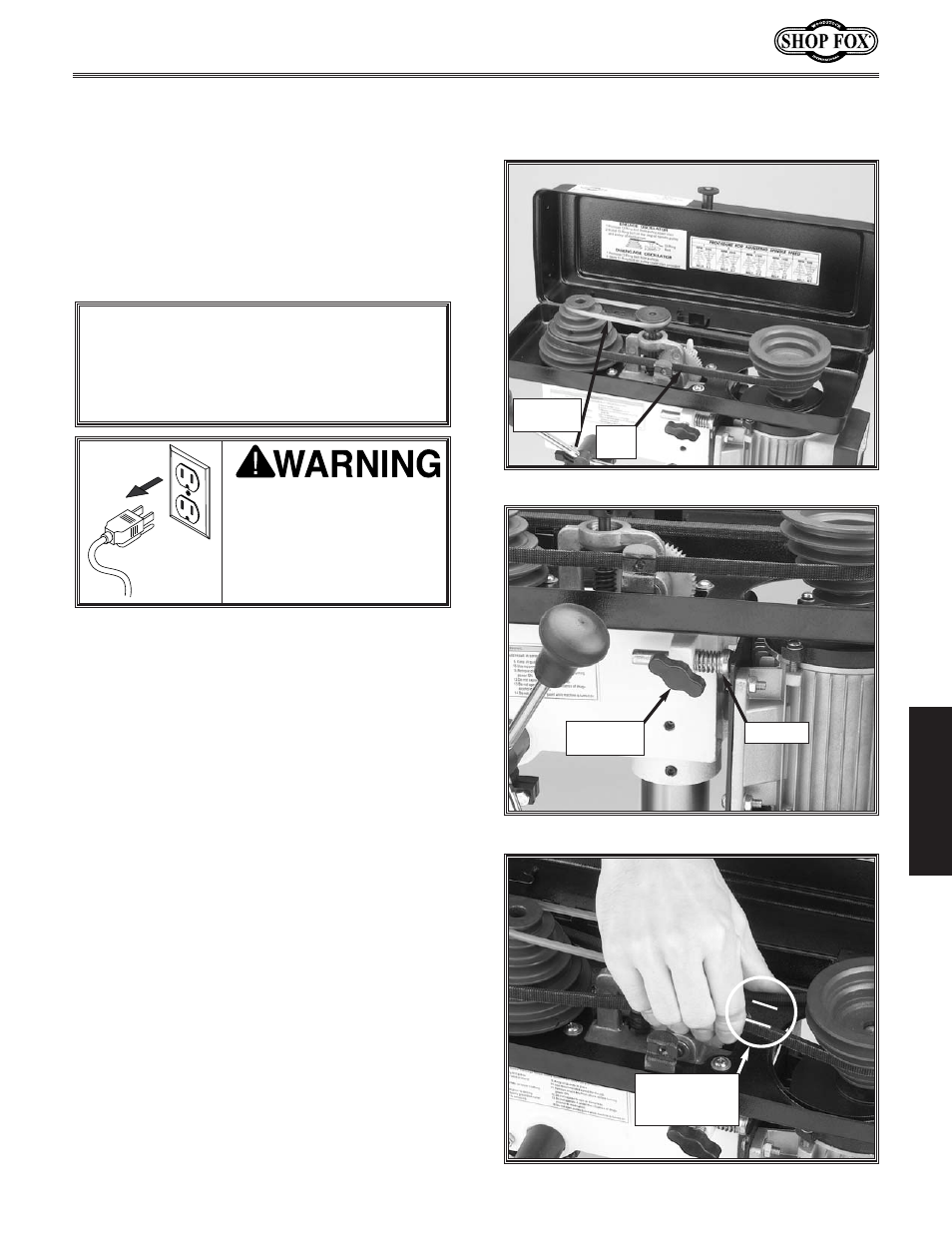

2. Open the belt cover. See Figure 15.

3.

Loosen the motor lock screw at the side of

the headstock. See

Figure 16.

4. Gently pivot the motor away from the

pushrod rubber until the belt is taut.

5. Hold the motor in position so the rubber

pad is held against the motor.

6. Tighten the lock screw, and make sure the

belt deflection gap is correct when pinched

together between the pulleys. See

Figure

17.

• If the gap between both inner sides of the

belt is greater or less than 1

1

⁄

2

" repeat

Steps 3 through 6 until the deflection gap

is 1

1

⁄

2

".

• If the deflection gap is 1

1

⁄

2

," close the

belt cover until it snaps shut.

The motor

will not start until the cover is closed.

NOTICE

The oscillator belt is not adjustable. If the

belt shows cracks or is slipping, replace the

belt with a new one.

MAKE SURE your machine

is unplugged during all

assembly, adjustments, or

maintenance procedures.

Otherwise serious personal

injury may occur!

Figure 15. Belt drive system.

Figure 16. Motor lock screw.

Figure 17. Measuring belt deflection.

Oscillator

Belt

Drive

Belt

Motor Lock

Screw

Pushrod

Belt Deflection

gap should be

about

1

1

⁄

2

"

ADJUSTMENTS

Belt Tension

ADJUSTMENTS