Depth stop, Adjusting table tilt – Woodstock SHOP FOX M1102 User Manual

Page 24

-22-

M1102/M1103 16-Speed Drill Press

O

PE

R

AT

IO

N

S

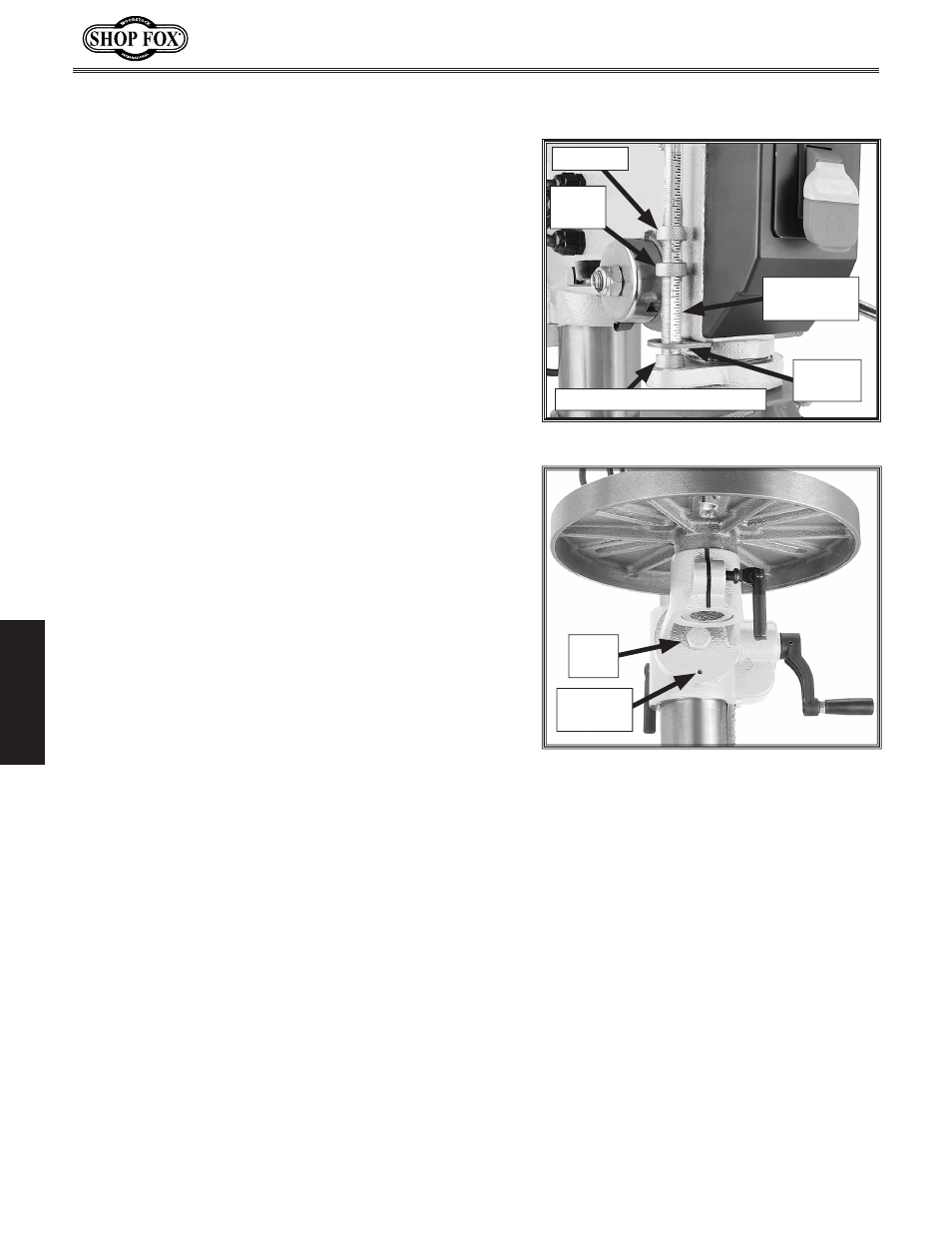

Figure 22. Depth stop components.

Jam Nut

Depth

Nut

Depth Stop

Stud

The Model M1102/M1103 has a depth stop that allows

you to drill repeated non-through holes to the same

depth every time.

The depth stop consists of a stud attached to the quill

with two knurled nuts that can be lowered or raised on

the stud so the lower nut (depth nut) hits a stop bracket

when the drill bit is lowered. The upper nut (jam nut)

is then used to tighten against the depth nut to secure

it in place so it doesn't move with repeated operations.

Figure 22 shows the various components of the depth

stop.

Depth Stop

To set the depth stop, do these steps:

1. Lower the drill bit to the required height.

2. Thread the depth nut down against the stop bracket.

3. Lower the jam nut against the depth nut.

4. Hold the depth nut in place and tighten the jam nut

against the depth nut.

Stop

Bracket

Along with the standard features of a table height hand

crank and a rotating table, this drill press has a 45° left/

right table tilt feature.

Adjusting Table Tilt

Figure 23. Table adjustment controls.

Locating

Pin

To tilt the table, do these steps:

1. Loosen the lock bolt.

2. Use a 3mm hex wrench to back out the locating pin

from the hole (

Figure 23) just enough so it allows

the table to tilt.

3. Tilt the table to the desired angle up to 45°.

4. Tighten the lock bolt.

5. To return the table to 0°, loosen the lock bolt, align

the arrow and the 0° mark on the angle scale, tight-

en the locating pin back into the hole, and tighten

the lock bolt.

Lock

Bolt

Return Height Control Nut