Feed shaft spring tension – Woodstock SHOP FOX M1102 User Manual

Page 32

-30-

M1102/M1103 16-Speed Drill Press

SE

RV

IC

E

Feed Shaft Spring

Tension

The feed shaft return spring is adjusted at the factory;

however, during the life of the drill press you may want

to adjust the feed shaft return spring so the pressure suits

your operating needs.

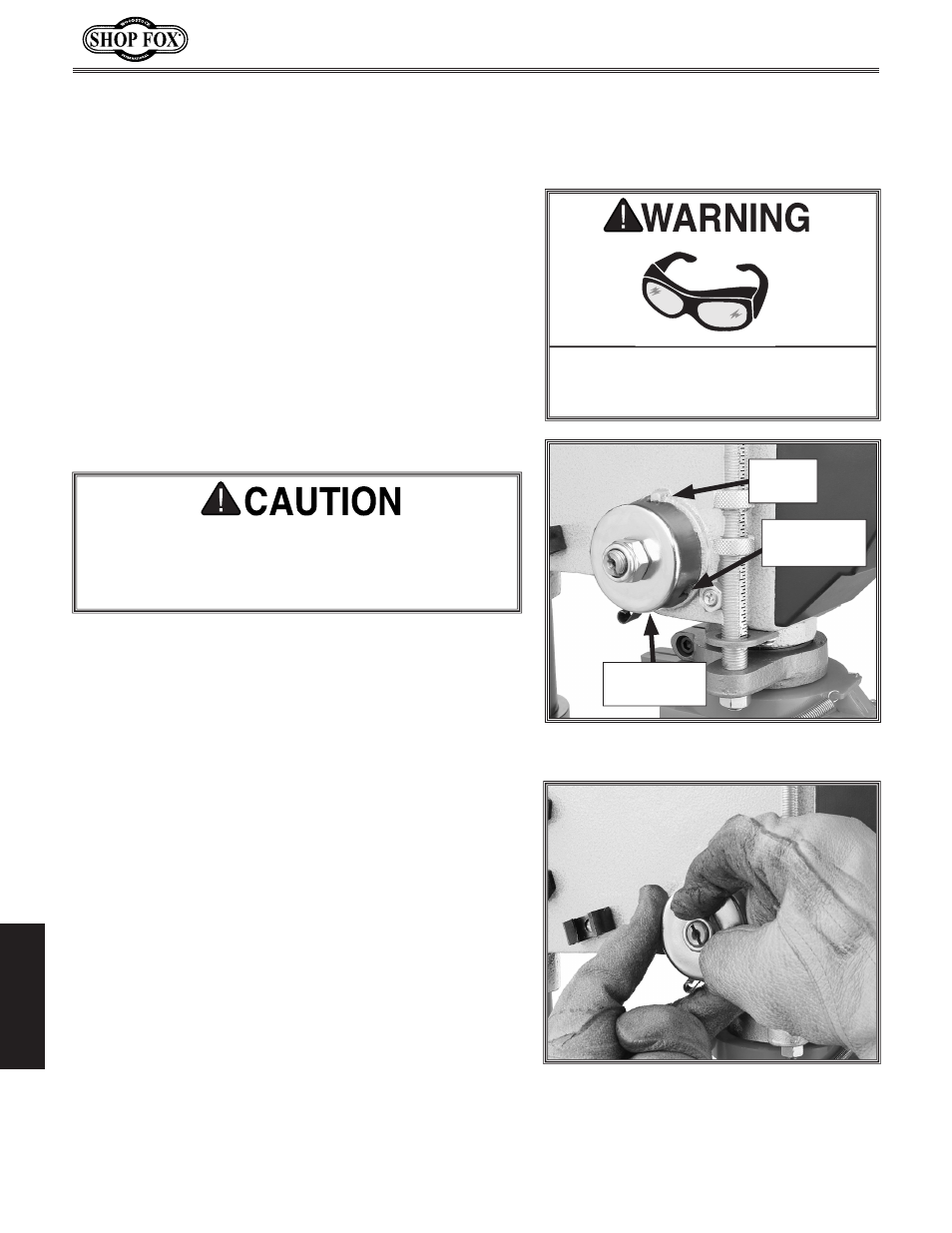

Figure 26. Feed shaft return spring

assembly.

To adjust the feed shaft spring tension, do these

steps:

1. DISCONNECT THE DRILL PRESS FROM POWER!

2. Wipe off any oil on the spring lock cover so it does

not slip in your fingers when you hold the cover from

spinning (see

Figure 26).

3. While holding the spring lock cover against the side

of the headstock so the cover stays splined with the

locking lug; loosen the cover nut approximately

1

⁄

4

"

(see

Figure 27).

4. Pull the cover outward just enough to disengage the

spring-cover lock slot from the locking lug.

Note: It is important to keep a good grip during this

step. Letting go of the cover will cause the spring to

rapidly uncoil.

5. Rotate the cover counterclockwise to increase spring

tension, or in the clockwise direction to reduce spring

tension.

6. Engage the next available spring-cover lock slot with

the locking lug and hold the spring lock cover tightly

against the side of the headstock.

7. Snug the cover nut against the spring cover just until

the nut stops, and then back off the nut approximately

1

⁄

3

turn, or just enough so there is no binding during

complete spindle travel.

8. Tighten the cover nut.

Spring Cover

Lock Slot

Spring Lock

Cover

Figure 27. Loosening cover nut.

A high tension coiled spring is underneath the cover.

Put on heavy leather gloves to protect yours hands

from possible lacerations when removing the cover

in the next step.

Locking

Lug

Wear safety glasses when adjusting the

coil spring. Serious eye injury may occur

if this warning is ignored!