6. use of indicator lights for troubleshooting – Miller Electric MR-5 User Manual

Page 25

5

-

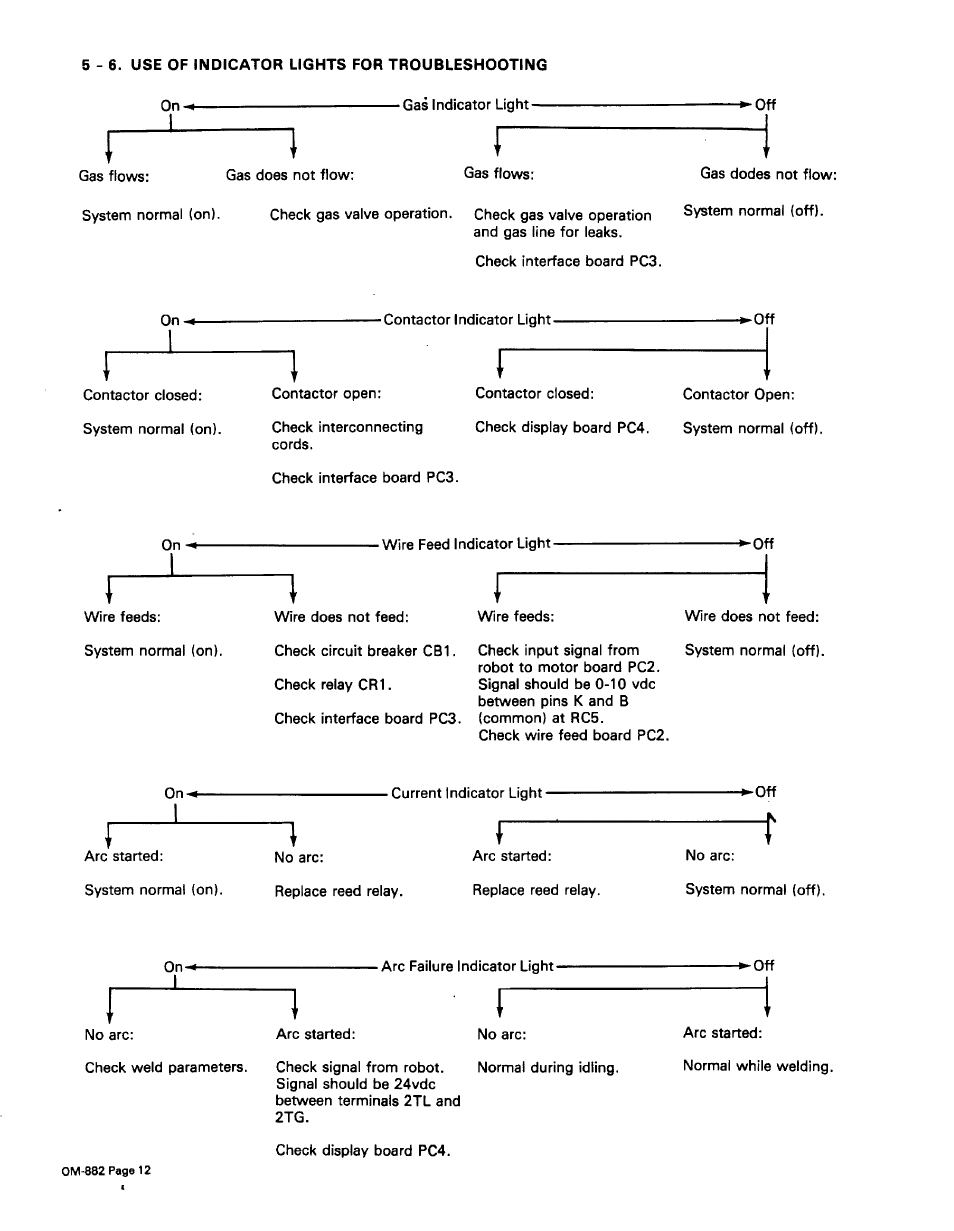

6. USE OF INDICATOR LIGHTS FOR TROUBLESHOOTING

Ga~ Indicator Light

I

Gas does not flow:

IF

Gas flows:

IF

Gas dodes not flow:

System normal (on).

Check gas valve operation.

Check gas valve operation

and gas line for leaks.

Check interface board PC3.

System normal (off).

-Contactor Indicator Light

Contactor closed:

System normal (on).

I,

IF

Contactor open:

Check interconnecting

cords.

Check interface board PC3.

Contactor closed:

Check display board PC4.

IF

Contactor Open:

System normal (off).

Wire Feed Indicator L.~,1

Wire feeds:

System normal (on).

Wire does not feed:

Check circuit breaker CB1.

Check relay CR1.

Check interface board PC3.

Wire feeds:

Check input signal from

robot to motor board PC2.

Signal should be 0-10 vdc

between pins K and B

(common) at RC5.

Check wire feed board PC2.

IF

Wire does not feed:

System normal (off).

On

I

—

Arc started:

System normal (on).

Current Indicator Light

No arc:

Replace reed relay.

Arc started:

Replace reed relay.

•Off

V

No arc:

System normal (off).

Arc Failure Indicator Ligl~

II

No arc:

Arc started:

Check weld parameters.

Check signal from robot.

Signal should be 24vdc

between terminals 2TL and

2TG.

Check display board PC4.

No arc:

Normal during idling.

Arc started:

Normal while welding.

On

Gas flows:

Off

On

Off

On

,~.1

On

-Off

OM-882 Page 12