5. troubleshooting chart – Miller Electric MR-5 User Manual

Page 23

c.

Slide spacers onto new meter support.

d.

Push meter into socket with meter supports

protruding through to rear of PC4.

e.

Reinstall lock washers and nuts to secure

meter to board. Do not

overtighten nuts or

meter may be damaged.

6. To install replacement display board, carefully

line board up with front panel openings for

meters and LED’s.

7.

Reinstall securing screws.

8.

Reconnect PLG2O and PLG24 to matching

receptacles on new PC4.

9.

Reinstall unit top cover.

B. Motor Board PC2 Replacement

1.

Remove unit top cover.

2.

Remove securing screw and unlatch standoff.

3. Gently pull board from receptacle RC5.

4.

Insert new board into RC5.

5.

Reinstall securing screw and latch standoff.

6.

Reinstall unit top cover.

C.

Replacement

Procedure

For

Remaining

Boards

1.

Remove unit top cover and locate board.

2. Disconnect plug(s) from board.

3.

Unlatch standoffs and

ing rail.

slide board

out

of retain-

WARNING:

4.

Slide new board into retaining rail and latch

stan-

doffs.

5. Connect plug(s) to matching receptacle(s) on

new board.

6. Reinstall unit top cover.

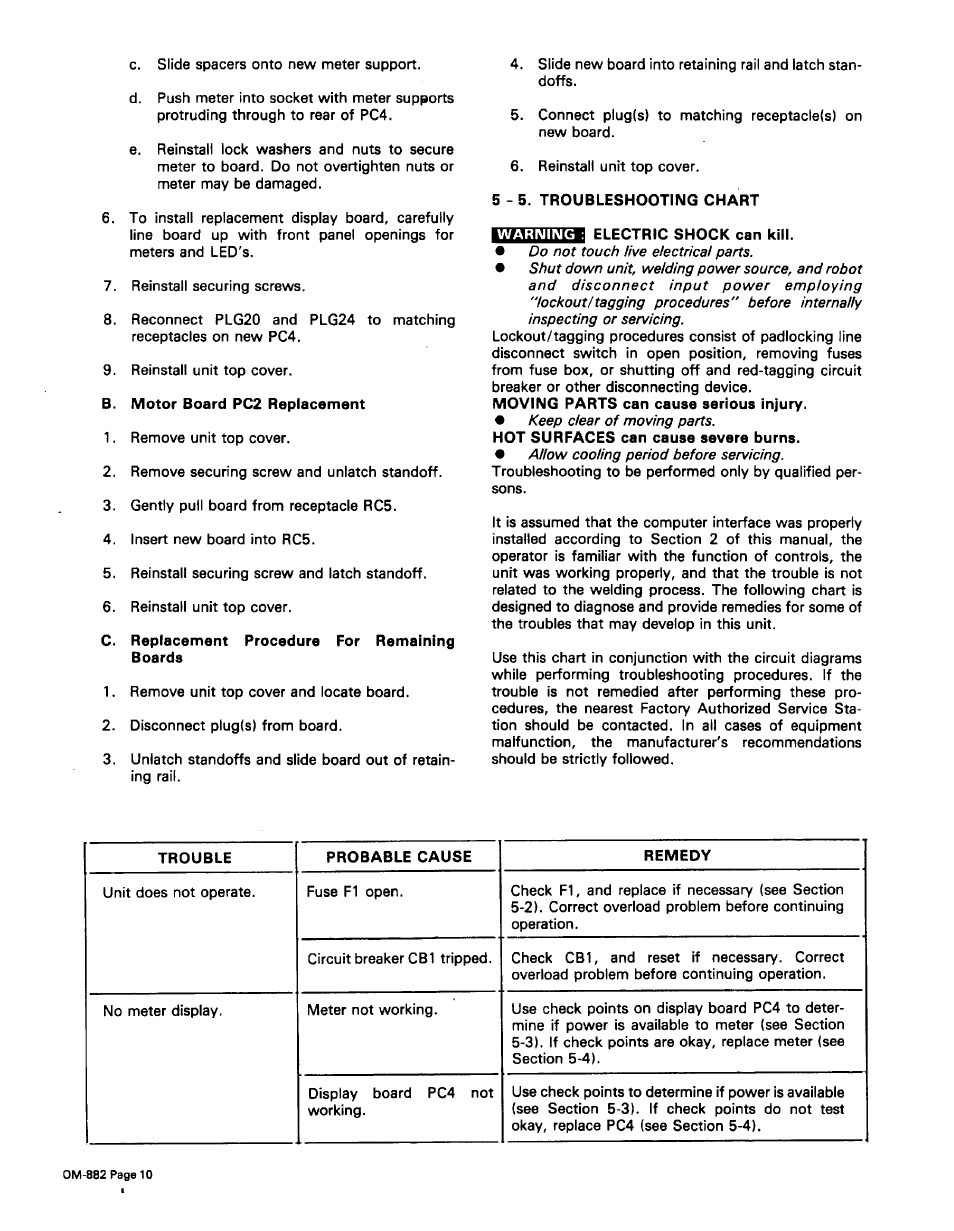

5 -5. TROUBLESHOOTING CHART

ELECTRIC SHOCK can kill.

•

Do not touch live electrical parts.

•

Shut down unit, welding powersource, and robot

and disconnect ,nput power employing

‘lockout/tagging procedures” before internally

inspecting or servicing.

Lockout/tagging procedures consist of padlocking line

disconnect switch in open position, removing fuses

from fuse box, or shutting off and red-tagging circuit

breaker or other disconnecting device.

MOVING PARTS can cause serious injury.

•

Keep clear of moving parts.

HOT SURFACES can cause severe burns.

•

Allow cooling period before servicing.

Troubleshooting to be performed only by qualified per-

sons.

It is assumed that the computer interface was properly

installed according to Section 2 of this manual, the

operator is

familiar with the function of controls, the

unit was working properly, and that the trouble is not

related to the

welding process. The following chart is

designed to diagnose and provide remedies for some of

the troubles that may develop in this unit.

Use this chart in conjunction with the circuit diagrams

while performing troubleshooting procedures. If the

trouble is not remedied after performing these pro-

cedures, the nearest Factory Authorized Service Sta-

tion should be contacted. In all cases of equipment

malfunction, the

manufacturer’s recommendations

should be strictly followed.

TROUBLE

PROBABLE CAUSE

REMEDY

Unit does not operate.

Fuse Fl open.

Check Fl, and replace if necessary (see Section

5-2). Correct overload problem before continuing

operation.

Circuit breaker CB1 tripped.

Check CBl, and reset if necessary. Correct

overload problem before continuing operation.

No meter display.

Meter not working.

Use check points on display board PC4 to deter

mine if power is available to meter (see Section

5-3). If check points are okay, replace meter (see

Section 5-4).

Display board

PC4 not

working.

Use check points to determine if power is available

(see Section 5-3). If check points do not test

okay, replace PC4 (see Section 5-4).

OM-882 Page 10