1. general information and safety, 2. receiving-handling, 3. description – Miller Electric MR-5 User Manual

Page 15: 2 - installation, 1. location, Installation

1

-

1. GENERAL INFORMATION AND SAFETY

A.

General

Information presented in this manual and on various

labels, tags, and plates on the unit pertains to equip-

ment design, installation, operation, maintenance, and

troubleshooting which should be read, understood, and

followed for the safe and effective use of this equip-

ment.

B. Safety

The installation,

operation,

maintenance, and

troubleshooting of arc welding equipment requires

practices and procedures which ensure personal safety

and the safety of others. Therefore, this equipment is to

be installed, operated, and maintained only by qualified

persons in accordance with this manual and all ap-

plicable codes such as, but not limited to, those listed at

the end of Section 1

-

Safety Rules For Operation Of

Arc Welding Power Source in the welding power source

Owner’s Manual.

Safety instructions specifically pertaining to this unit ap-

pear throughout this manual highlighted by the signal

words

and

which identify

different levels of hazard.

WARNING

CAUTION

carefully followed could result in minor personal injury

or damage to this equipment.

A third signal word,

•s•s,

highlights instruc-

tions which

need special emphasis to obtain the most

efficient operation of this equipment.

1

-

2. RECEIVING-HANDLING

-

Before installing

this equipment, clean all packing material from around

the unit and carefully inspect for any damage that may

have occurred during shipment. Any claim for loss or

damage that may have occurred in transit must be filed

by the purchaser with the carrier. A copy of the bill

of lading will be furnished by the manufacturer on re-

quest if occasion to file claim arises.

When requesting information concerning this equip-

ment, it is essential that Model Description and Serial

Number of the equipment be supplied.

1

-

3. DESCRIPTION

-

The computer interface con-

trol contains wire feed speed, weld voltage, and weld

amperage control circuitry, digital ammeter, voltmeter,

and wire feed speed meter, and circuitry to interface

with the robot control. The control is shipped for opera-

tion in the constant voltage mode but has constant cur-

rent capabilities.

WARNING

CAUTION

statements include installation, operation,

and maintenance procedures or practices which if not

carefully followed could result in serious personal injury

or loss of life.

statements include installation, operation,

and maintenance procedures or practices which if not

SECTION 2

-

The gas/current sensing control contains the gas valve

and current sensing reed relay.

These components function with the robot system

when using the Gas Metal Arc Welding (GMAW) pro-

cess.

INSTALLATION

2

-

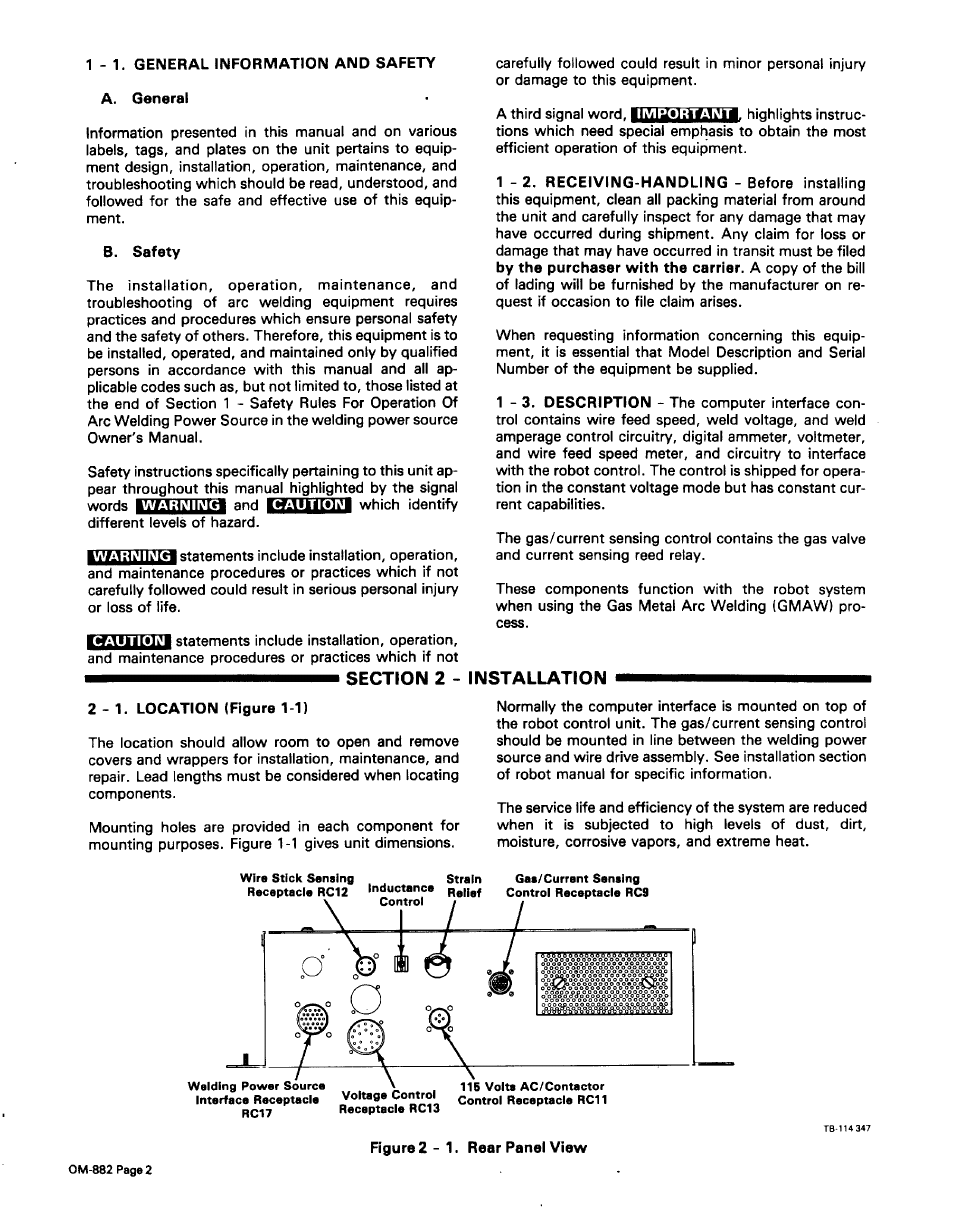

1. LOCATION (Figure 1-1)

The location should allow room to open and remove

covers and wrappers for installation, maintenance, and

repair. Lead lengths must be considered when locating

components.

Mounting holes are provided in each component for

mounting purposes. Figure 1-1 gives unit dimensions.

Normally the computer interface is mounted on top of

the robot control unit. The gas/current sensing control

should be mounted in line between the welding power

source and wire drive assembly. See installation section

of robot manual for specific information.

The service life and efficiency of the system are reduced

when it is subjected to high levels of dust, dirt,

moisture, corrosive vapors, and extreme heat.

re-114 347

Wire Stick Sensing

Strain

Gas/current Sensing

Receptacle RC12

Inductance

Relief

control Receptacle RC9

control

Welding Power Source

115 Volts Ac/contactor

Interface Receptacle

Voltage control

control Receptacle Rd 1

RC17

Receptacle RC13

Figure 2

-

1. Rear Panel View

OM-882 Page 2