Miller Electric MR-5 User Manual

Page 17

A. Wire Stick Sensing Connections

1.

Align keyway, insert

four-socket Amphenol plug

into matching receptacle on computer interface,

and rotate threaded collar fully clockwise.

2.

Connect lead with ring terminal to welding

power source positive output terminal.

3.

Connect lead with clamp to welding power

source negative output terminal.

B.

Voltage Control Connections

1. Align keyway, insert 17-socket plug into mat-

ching receptacle on computer interface, and

rotate threaded collar fully clockwise.

2. Align keyway, insert 17-pin plug into matching

receptacle on welding power source, and rotate

threaded collar fully clockwise.

C.

115 Volts AC/Contactor Control Connec-

tions

Two cords are necessary for this connection. One cord,

supplied with the welding power source, has a 14-pin

Amphenol plug and two twistlock receptacles. The se-

cond, supplied with the robot, has two twistlock plugs

and a four-pin Amp plug.

1. Align keyways, insert four-pin Amp plug into

matching receptacle on computer interface, and

rotate threaded collar fully clockwise.

2.

Connect the twistlock receptacles to the mat-

ching plugs, and rotate plugs clockwise.

3. Align keyway, insert 14-pin Amphenol plug into

matching receptacle on welding power source,

and rotate threaded collar fully clockwise.

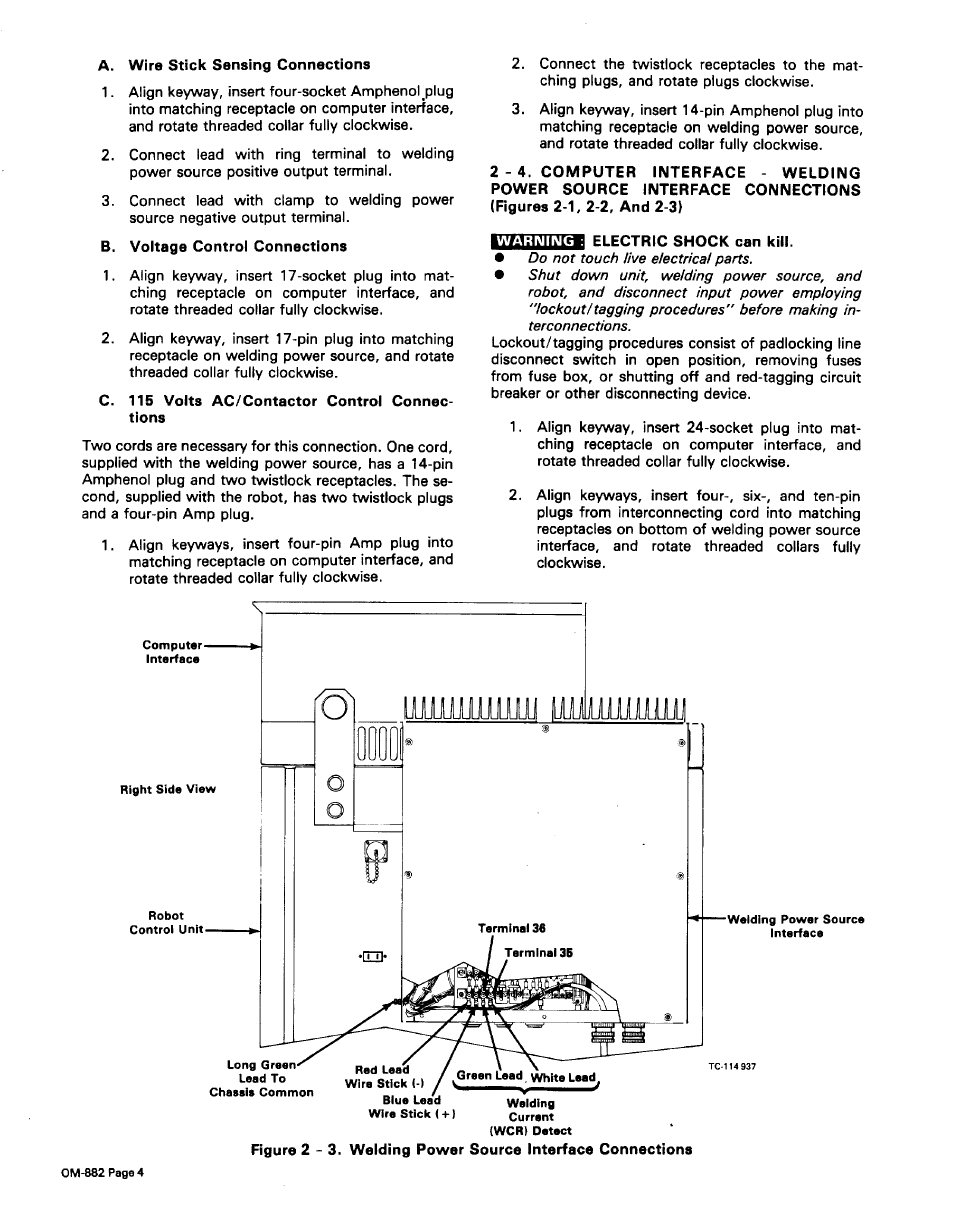

2

-

4. COMPUTER

INTERFACE

-

WELDING

POWER SOURCE

INTERFACE CONNECTIONS

(Figures 2-1, 2-2, And 2-3)

WARNING: ELECTRIC SHOCK can kill.

•

Do not touch live electrical parts.

•

Shut down unit, welding power source, and

robot, and disconnect input power employing

‘lockout/tagging procedures” before making in-

terconnections.

Lockout/tagging procedures consist of padlocking line

disconnect switch in open position, removing fuses

from fuse box, or shutting off and red-tagging circuit

breaker or

other disconnecting device.

1.

Align keyway, insert 24-socket plug into mat-

ching receptacle on computer interface, and

rotate threaded collar fully clockwise.

2.

Align keyways, insert four-, six-, and ten-pin

plugs from interconnecting cord into matching

receptacles on bottom of welding power source

interface, and rotate threaded collars fully

clockwise.

Power Source

Welding

Current

(WCR) Detect

Figure 2

-

3. Welding Power Source Interface Connections

OM-882 Page 4