6. connecting weld cables and gas hoses – Miller Electric DS-64M Swingarc User Manual

Page 17

OM-1588 Page 13

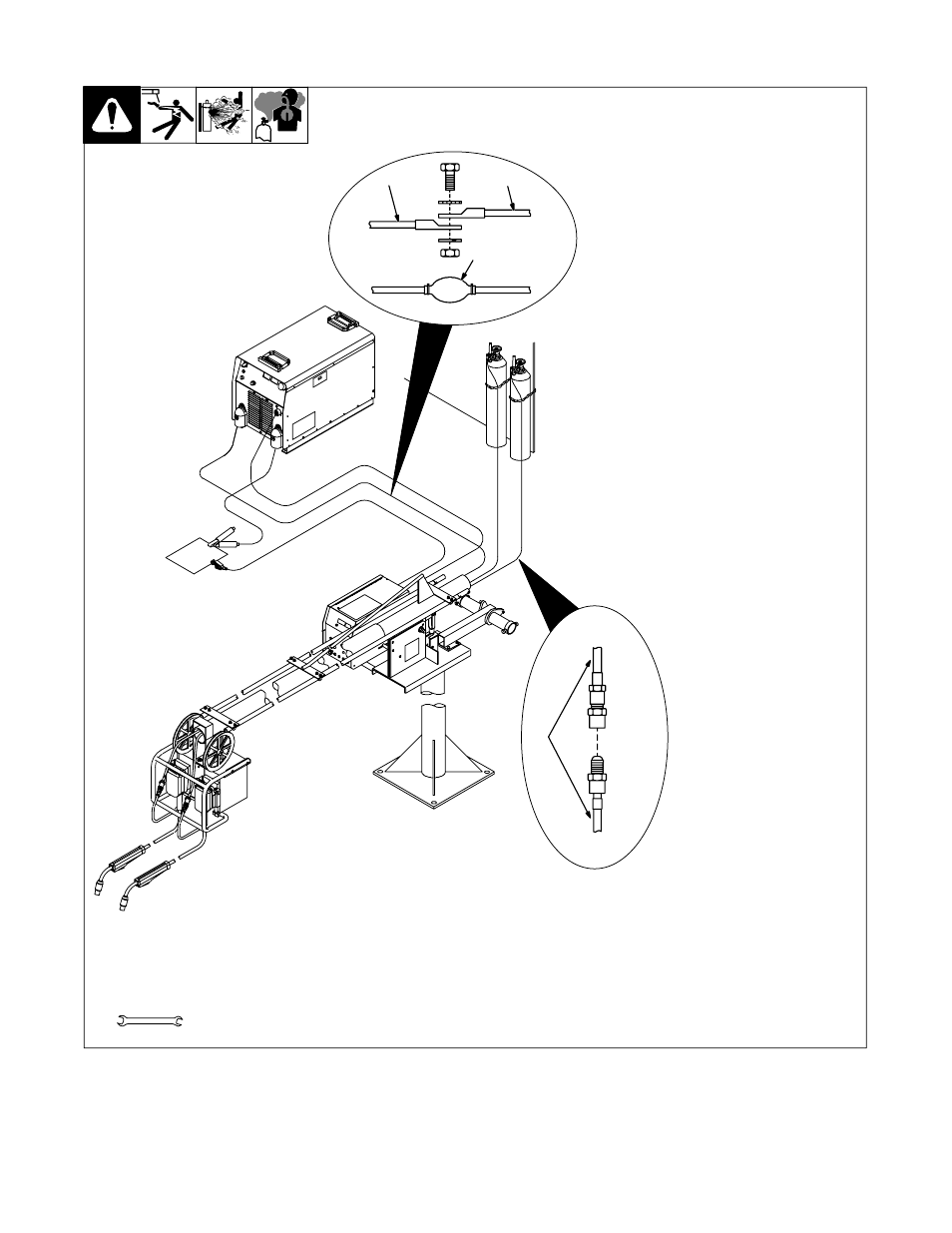

4-6. Connecting Weld Cables And Gas Hoses

Ref. ST-801 806 / Ref. ST-152 800-A

Tools Needed:

5/8 in

The weld cables and shielding gas

hoses extend 10 ft (3 m) from the

boom.

Route weld cables from boom

through reed relays, if applicable.

If the welding power source or gas

supply are further from the boom,

extend cables or hoses as follows:

1

Weld Cable

2

Insulated Sleeving

Bolt together weld cables from

welding power source and boom.

Use electrical tape and insulated

sleeving to cover connection.

3

Shielding Gas Hose

Connect hose to gas supply or ex-

tension hose. The hose from the

boom has 5/8-18 right-hand

threads.

1

1

2

3

Gas Supply

Boom

See also other documents in the category Miller Electric Tools:

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)