Flex vent installation – Monessen Hearth Direct Vent Gas Fireplace HBDV300 User Manual

Page 27

54D5031

27

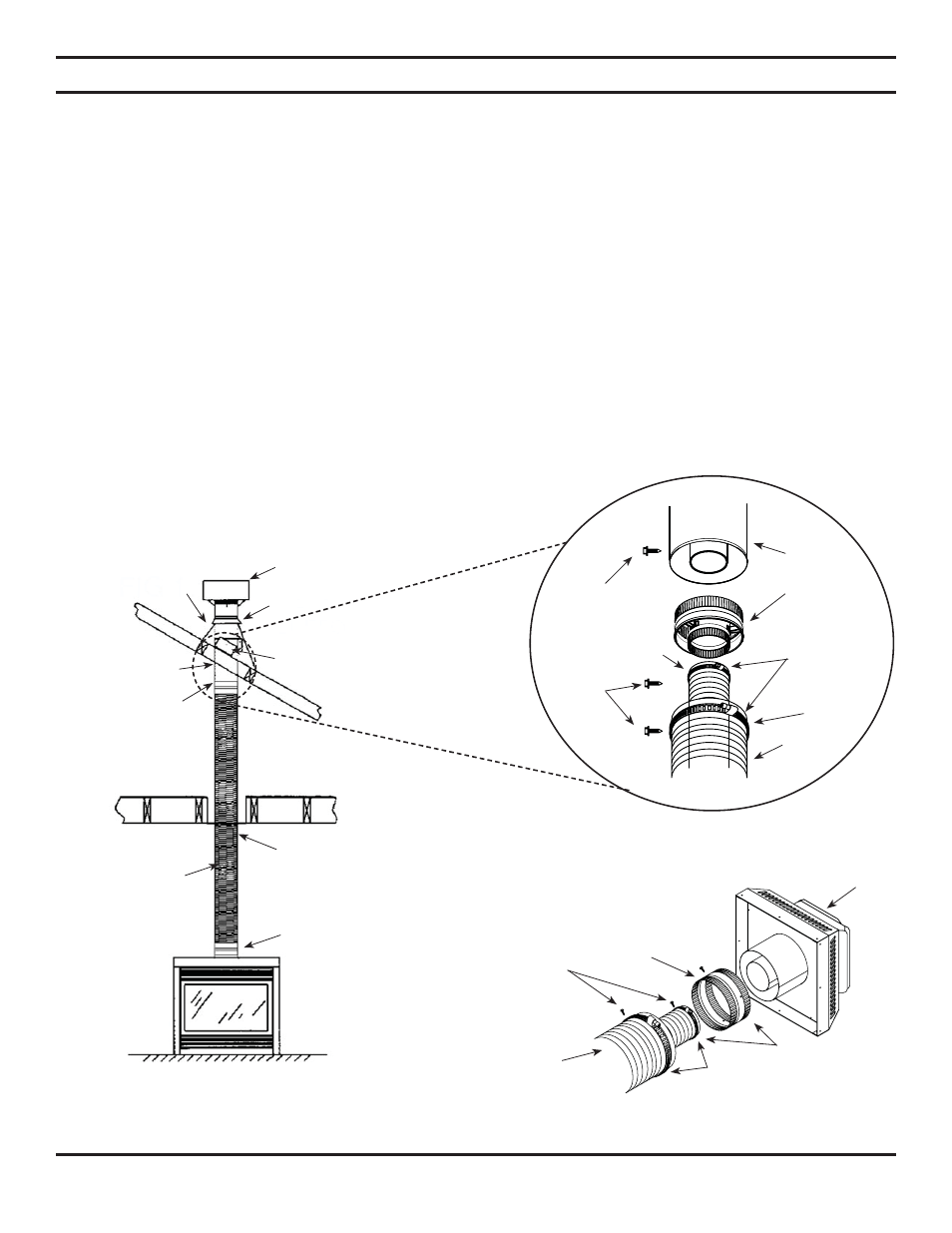

FLEX VENT INSTALLATION

Figure 4 — Typical pipe connection

Figure 3 —

Typical vertical fl ex vent installation

Figure 5 —

Typical horizontal fl ex vent installation

Termination

cap

Storm collar

Flashing

Rigid pipe

length

Flex to pipe

adapter

(FPA/8)

Fire stop

UL1777 fl ex pipe

DVFA/8 Adapter

Roof support

UL1777

Flex vent

Monessen horizontal

vent termination

Gear

clamps

1¾ in. fl exible pipe

and termination outer

collar overlap

Securing screws

(three places

equidistant, just

above gear clamp)

Termination to fl ex

adapter (FTA7/8)

UL1777

Flex vent

Securing

screws

(3 places

equidistant

just above

gear clamp)

Gear clamp

1¾ in. fl exible pipe

and adapter outer

collar overlap

Rigid pipe

length

Gear

clamp

Flex to pipe

adapter

(FPA/8)

3. Do not allow the fl exible vent to bend in radius tighter than 5" (127mm). Refer to Figure 2.

4.

Horizontal

runs

of

fl exible vent shall be supported at maximum 2 foot intervals; vertical runs, fi ve feet

intervals. Metal strapping, properly secured, is an acceptable means to support the fl exible vent.

5. Flexible vent spacers are to be installed at intervals prescribed by the fl exible vent manufacture; and in such a

way as to maintain concentric inner and outer vent spacing.

D.

Attaching

fl exible venting to vertical termination assemblies.

1. When using Simpson pipe, a MHS fl ex-to-pipe adaptor and/or rigid pipe section(s) is required to connect the

fl exible vent assembly to the vertical termination by using three self penetrating screws.

2.

Review

Figure 4 and corresponding instructions for proper overlap, clamp and screw placement.

3. Three each self penetrating screws are drilled opposite one another and below the gear clamp.

4. Use only listed and approved terminations and accessories, installed per the installation instructions and

Figure 3.

E.

Installing

fl exible venting to horizontal termination assemblies.

1.

Connect

the

4"

fl exible vent to the horizontal termination as in Figure 5.

2. Slide termination cap adapter ring over the termination cap’s outside pipe and secure with three screws.

3.

Connect

the

7"

fl exible vent to the termination adapter ring as in Figure 5.

4.

Review

Figure 5 for proper overlap and clamp placement

5. Three each self penetrating screws are drilled opposite one another and below the gear clamp.

6. Use only listed and approved terminations and

accessories, installed per the termination instructions

and

Figure 5.