1. feeder drive assembly maintenance – Miller Electric XR Control User Manual

Page 37

OM-1594 Page 31

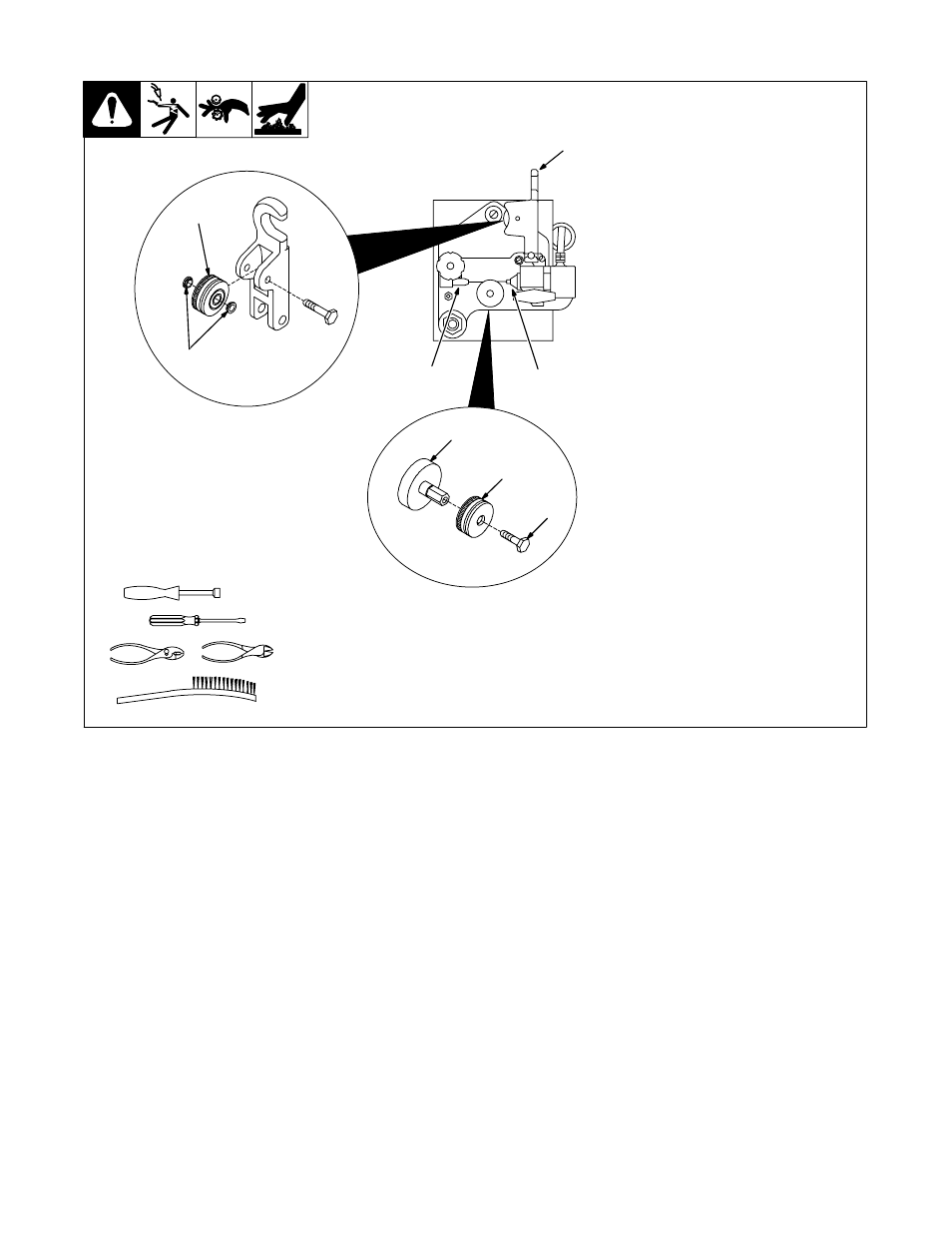

7-1. Feeder Drive Assembly Maintenance

802 193-A

Retract wire onto spool.

1

Pressure Roll Assembly

2

Drive Motor Shaft

3

Drive Roll

4

Screw

Use wire brush to clean drive roll.

5

Drive Roll Idler

6

Shoulder Washers

Use wire brush to clean idler.

7

Outlet Guide

8

Wire Inlet Guide

Pull guide toward rear of feeder to

remove. Install new guide.

Thread welding wire and adjust

drive roll pressure, if necessary

(see Section 5-12).

Drive roll and idler are available for

the following wire size ranges:

.030-.035 wire size

.047 wire size

.062 wire size

When changing wire size, change

control box drive roll and idler, gun

pressure roll and drive roll (see

Section 7-2 for XR-Edge guns; see

Sections 7-6 and 7-7 for pistol-grip

guns), and gun liner (see Section

7-3 for XR-Edge guns; see Section

Tools Needed:

3

4

2

1

8

7

5/16 in

5

6

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)