8. meter circuit board settings – Miller Electric XR Control User Manual

Page 25

OM-1594 Page 19

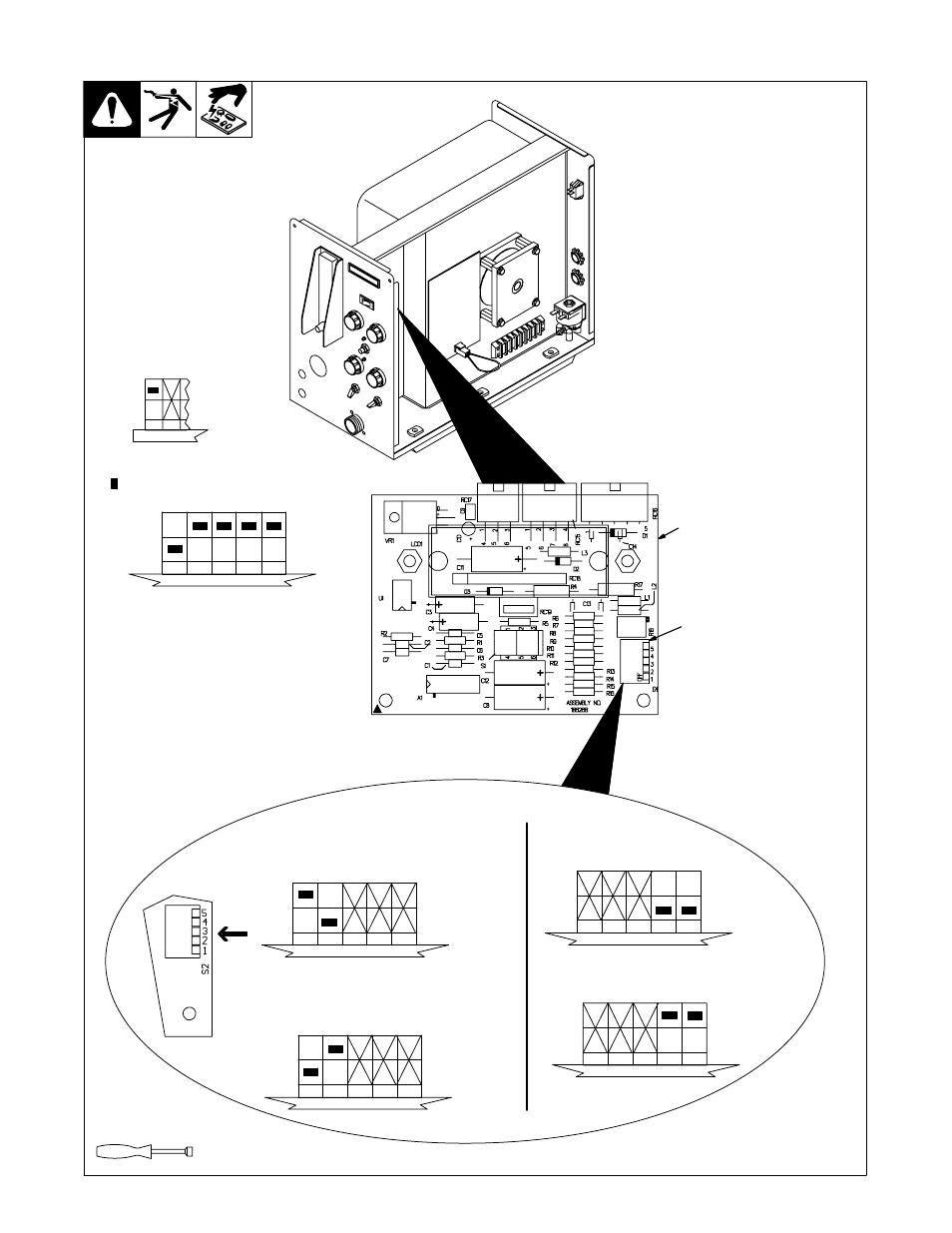

5-8. Meter Circuit Board Settings

Ref. 802 359 / Ref. 186 266

Tools Needed:

1/4 in

1

Meter Board PC2

2

DIP Switch S2

Set DIP switch S2 for type of

welding power source, and desired

wire feed speed display.

Reinstall hinged door and side

panel.

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

Or

Or

Meters/Minute

Inches/Minute

Digital Meter Display

Arc Voltage Sensing Using Voltage Sensing

Lead For Welding Power Source That Does

Not Support Pins F And H

Voltage Sensing Function

Arc Voltage Sensing Using Feedback From

Welding Power Source That Does Support

Pins F And H

1

2

X Means switch position does not affect

specified function.

. Means switch must be in this position.

2

1

.

For sense lead, connect PLG51 to PLG50.

Before feeder can be used with a power

source that does not support pins F and H, a

voltage sensing lead must be installed in feed-

er. Volt sensing lead kit 209867. See section

5-7 for information regarding installation of

voltage sensing lead.

For voltage feedback, connect PLG51 to

PLG52.

1

2

3

4

5

Switch settings from the factory.