11. installing wire spool – Miller Electric XR Control User Manual

Page 27

OM-1594 Page 21

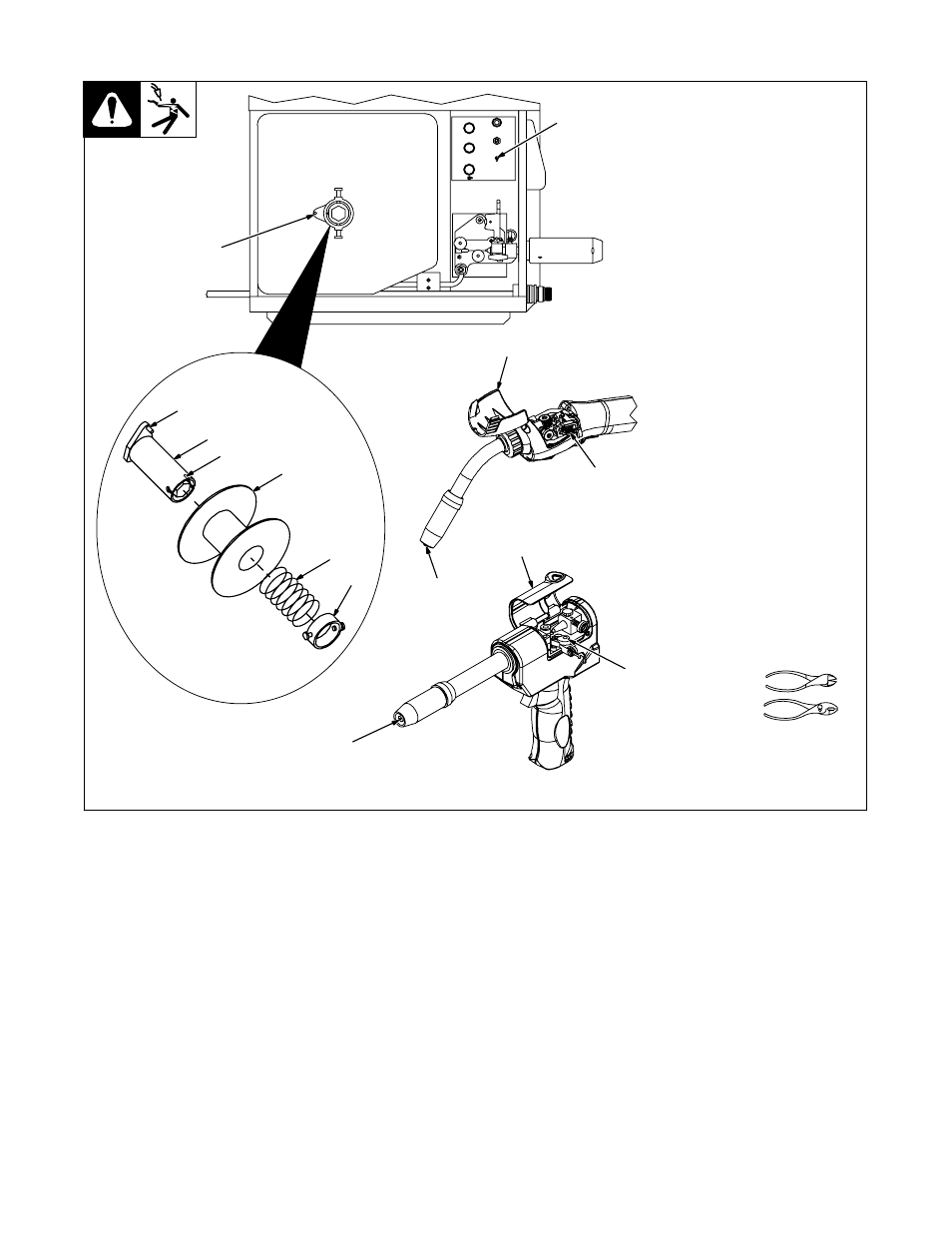

5-11. Installing Wire Spool

Ref. 801 578-A / Ref. 072 573-B / Ref. 801 556-C / Ref. 151 599-F

1

Wire Spool

2

Top Cover

3

Pressure Roll Assembly

4

Gun Contact Tip

If wire spool is being replaced, open

top cover, open pressure roll as-

sembly in gun, and cut welding wire

off at contact tip.

Retract wire onto spool.

5

Hub

6

Hub Pin

7

Notch

8

Compression Spring (Optional

For 8 Inch Spool)

9

Retaining Ring

Slide spool onto hub so wire feeds

off bottom. Turn spool until hub pin

fits hole in back of spool (notch on

hub aligns with hub pin for guid-

ance). Reinstall retaining ring.

10 Motor Torque Switch

Place motor torque switch in

appropriate position for wire type

and size (see Section 6-2).

Thread welding wire (see Section

5-12).

Tools Needed:

6

5

1

9

8

2

3

4

10

6

7

2

4

3

See also other documents in the category Miller Electric Tools:

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)