MITSUBISHI ELECTRIC Mitsubishi Home Refrigerator MR-G50J-SS-NZ User Manual

Page 18

18

Ice making test completes

about 20 seconds later.

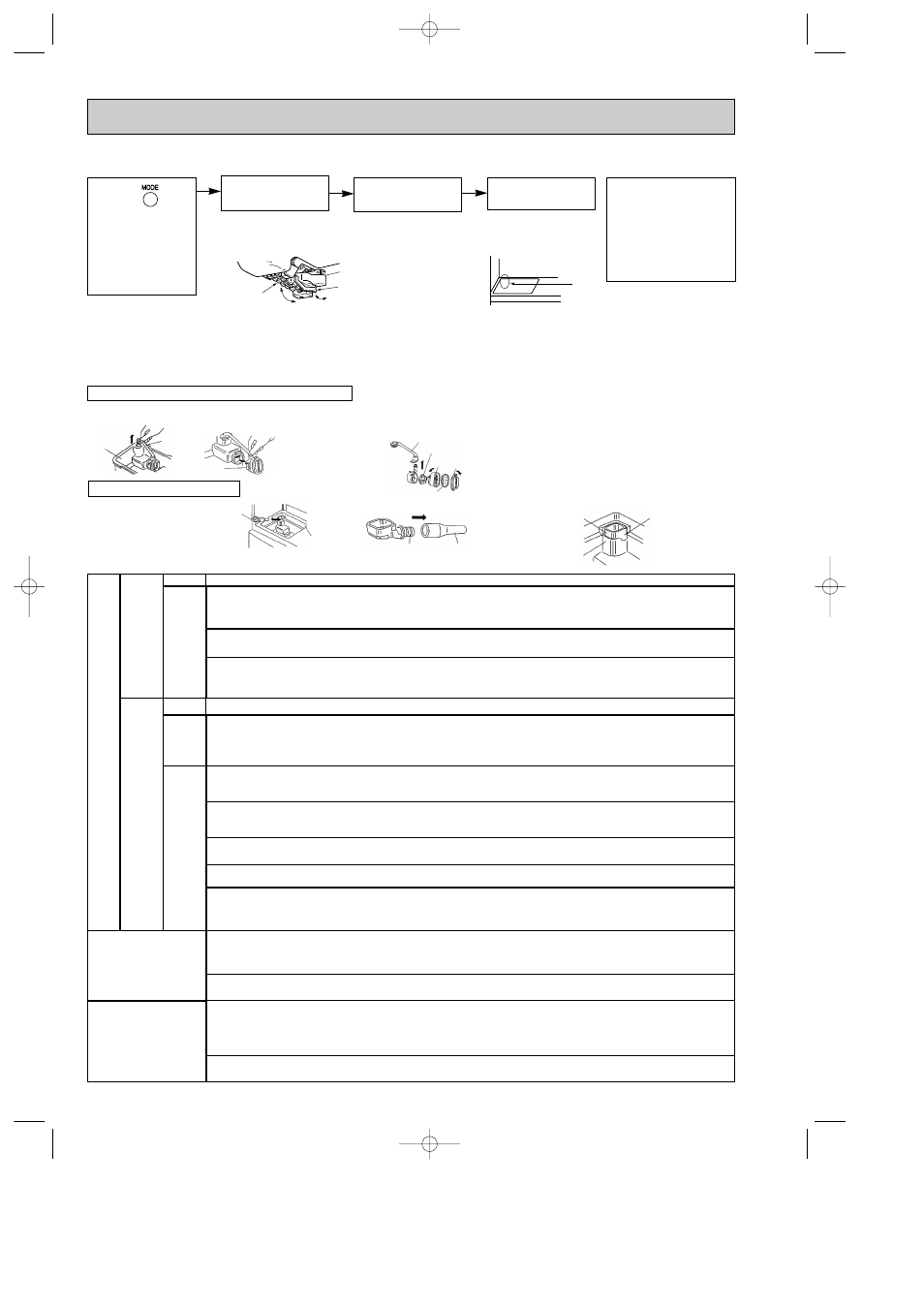

(3) Operation by ice making test

Press the switch

for 5 seconds or

more.

(See “• Self check

and error display

method and opera-

tion,

1

Ice making

test operation” at

page 14.)

Ice stock detective

lever detects the

amount of ice.

Detective lever once

come down to detection

point then return to the

original position.

The ice tray is

rolled over and the

system is reset.

The ice tray rolls

over once to drop

the ice, then return

to the original posi-

tion.

Water pump motor

is operates.

Remove the lid of

the water tank then

check the sounds

of water running.

Completion

When abnormality

occurs, the error code

is displayed on the

panel.

Inspect the abnormal

points by referring to

page 15, 16.

Ice tray

Detection lever

(Upper freezer compartment)

(Lower-left part of refrigerator compartment)

[Check point of automatic ice maker operation]

*Never touch the automatic ice maker while it is operating.

After the operational test, a popping sound is heard several times because the operation of three-way valve is checked auto-

matically. During the operation, do not insert a hand into the automatic ice maker.

(4) Maintenance for water pump and water pipe

Check here.

Water

supply

pipe

Water pipe · Tank holder

1. Pull out water supply

pipe. Wipe the tank

holder with clean cloth.

•Do not let water flow into

the tank holder.

packing

2. Separate pieces and wash with water.

Light-type bacteria removing filter

Water pump

1. Pull out the pipe. 2. Turn the tank

pump to detach.

5. Put the parts back in the reverse order of disa-

ssembly.

3. Pull out the tank pipe, turn the cap

to remove, and then wash

the propeller with water.

•The propeller is

made of the magnet.

Wash it well with water

so that no alien sub-

stance remains on it.

4. Remove the light-type bacteria removing filter

and wash it in water.

Normally the filter need not be replaced. However, replace it

in the following condition:

•When the filter is clogged by passing something other than

water through the filter.

•When the filter is broken.

In such a case, contact the dealer that you purchased this

refrigerator.

Cap

Propeller

Tank pipe

Cover

Tank

pipe

Water

tank

Water pump & Light-type bacteria removing filter

3. Reverse steps to replace the pipe.

Tank holder

Aluminum pipe

Side A

Side B

Water pipe

•Replace the water

pipe.

Be sure that sides A

and B fit flush to

each other.

•Twist the

aluminum

pipe to

replace it.

(5) Troubleshooting for automatic ice-maker

T

rouble with ice-making

W

ater or ice is

on the ice tray

The ice-maker gear box may be defective, cooling may be poor or ice cubes may be full in the server.

3.Check if the temperature of the freezer com-

partment is cool enough.

(It takes longer to make ice during summer

time or if the door is frequently opened.)

2.Measure the resistance of ice tray thermistor

circuit.

1.Check inside of the ice server.

The water saucer may be defective, or the ice tray may get cracked.

4. Check the water pipe between the refrigerator

compartment and freezer compartment for dirt,

and foreign objects.

5.Check the condition of ice tray.

6.Disassemble the water pump and check the

inside of the pipe.

7.Tank pipe is clogged , has a hole or is not

properly installed.

8.Check the motor coil resistance.

9.Check if there are any dirt or foreign object

which are difficult to remove in the water tank.

Also, check if there is any crack or deformation

on the tank.

The ice does not

come out from

the tray

No water or ice

in the ice tray

W

ater in

water

saucer

No waterdrops in water saucer

Water in the tank

holder

Chained ice,

Water leaking from

the ice server

10.Check the water pipe for dirt, and foreign

objects. Also, check the water pipe position and

connection.

11.Check the water pipe (between F.compartment

and R.compartment) for clogging.

12.Check the water pump operation by the ice-

making test.

13.Water spill at the installation of water tank or more water over the full water level may cause to from

chained ice.

14.Measure the water pump coil resistance.

•

Ice cubes are not stored flatly

and the amount is detected as

full.

•

Food inside the ice server

•Open circuit (

∞

'

) or

short circuit (0

'

)

•Not enough

➔

Inspection

➔

Replace the ice tray

thermistor.

➔

Poor cooling

➔

Clean the water pipe.

➔

Defrost

•Broken or cracked

•Not placed properly

➔

Replace the tray.

➔

Reinstall it properly.

•Dirt or foreign objects

➔

Repair and explain to

the user for proper

usage.

•Clogging, disconnecting

•Hole or crack

➔

Check the water

pump.

•Crack or deformation

➔

Change the water

tank.

•Clogging, disconnecting

•Hole or crack

•Clogging

➔

Clean / Remove the

dirt.

•Water filling time is longer

than 9 seconds.

➔

Replace the control

board.

•Open or short circuit

➔

Change the water

pump motor.

•

Clogging

•

Freezing (For freezing, check

the pipe heater resistance.

➔

Clean / Reinstall it properly.

➔

Change the tank pipe.

•Open or short circuit

➔

Clean / Reinstall it

properly.

➔

Replace the pipe.

OA090-1.qxp 06.7.20 9:55 AM Page 18