Milwaukee 4262-1 User Manual

Page 9

page 9

Drilling

When preparing to drill, align the bit with the spot to be drilled. When

proper alignment is established, energize the magnet and start the drill

motor. A pilot hole is recommended for drilling holes larger than 1/2

in diameter. When drilling, apply only enough force to produce a curled

chip. Applying too little force will result in small broken chips and in-

creased drilling time. Applying too much force will cause overheating of

the bit resulting in short bit life. Overheating of the bit can be noticed

when drill bit and chips turn brown or blue. Excessive force can cause

the drill to slow down to a point where drilling time will increase. The use

of cutting lubricants will reduce drilling heat and increase drill bit life.

Using Twist Drills

When preparing to drill, align the bit with the area to be drilled. When

proper alignment is established, energize the magnet and start the drill

motor. A pilot hole is recommended for drilling holes larger than

1/2" in diameter.

When drilling, apply only enough force to produce a curled chip. Applying

too little force will result in small broken chips and increased drilling time.

Applying too much force will cause overheating of the bit resulting in

short bit life. Overheating of the bit can be noticed when drill bit and chips

turn brown or blue. Excessive force can cause the drill to slow down to

a point where drilling time will increase. The use of cutting lubricants will

reduce drilling heat and increase drill bit life.

APPLICATIONS

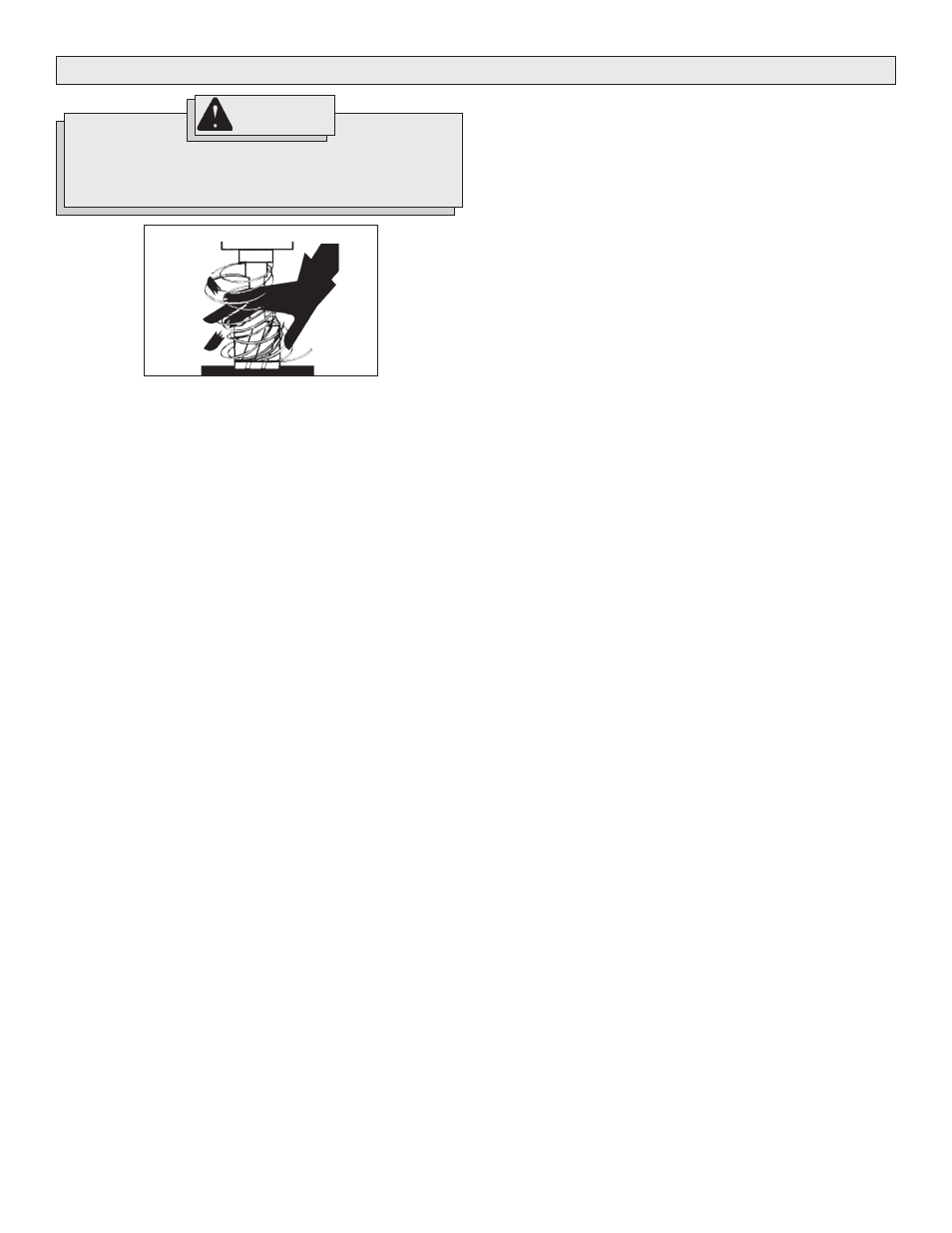

To reduce the risk of injury, always keep hands, rags,

clothing, etc. away from moving parts and chips. Do not try

to remove chips while the cutter is rotating. Chips are sharp

and can pull objects into moving parts (See Fig. 11).

Fig. 11

Tapping

Select the proper tap and drill combination. Refer to the Maximum Rec-

ommended Capacity chart. On two-speed drill motors, use the low

speed shift setting. Drill the hole as described above. If possible, tap the

hole before moving the base to another position. This eliminates the need

to align the tap with the hole. Always use a quality tapping wax or oil for

smooth cutting and avoid damage to the tap or workpiece. Pipe taps are

not recommended

1. Insert the tap into the chuck. TIGHTEN THE CHUCK SO THAT THE

CHUCK JAWS GRIP THE ROUND PORTION OF THE SHANK AND

NOT THE FLATS OF THE TAP.

2. For tapping existing holes, align the tap so it is centered with the hole

and reenergize the base.

3. Lubricate the tap and hole and lower the tap onto the work surface.

Turn the drill speed control to the slowest setting and push the Drill

Fwd button (Drill Rev for the left hand threads) to start the drill

motor. Adjust the speed control knob so the tap turns slowly and

smoothly into the hole.

4. When using smaller taps, reverse the motor as soon as the tap breaks

through the hole. With large taps, reverse the motor as soon as the

first full thread is exposed, the motor does not have to be stopped

before changing directions.

5. Reverse the motor to slowly withdraw the tap from the hole. Main-

tain light pressure on the handle to compensate for the weight of the

drill motor on the tap. As soon as the tap comes out of the hole, raise

the motor and tap clear of the workpiece.

NOTE: Only the low speed shift setting on the 2-speed drill is recom-

mended for tapping.

DANGER!