Fig. 4a fig. 5, Fig. 4 – GE GXSF39E User Manual

Page 7

7

GEAppliances.com

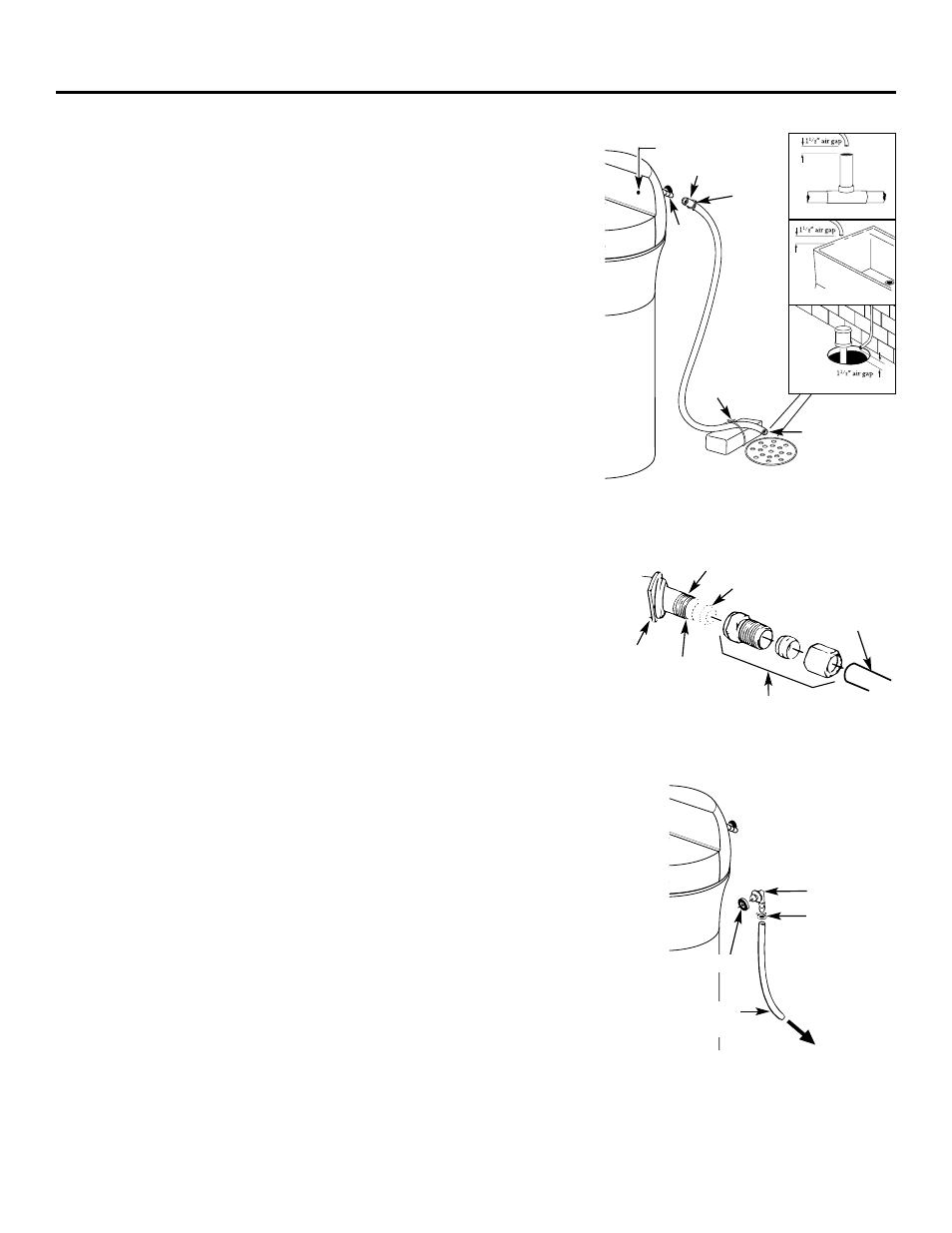

Fig. 4A

Fig. 5

To sewer drain

Overflow

drain hose

Hose clamp

Grommet

Clip

1/4

″ NPT threads

Barbs

1/2

″ O.D.

copper tube

(not furnished)

Cut barbs

from drain

fitting

Compression fitting,

1/4

″ NPT X 1/2″ O.D. tube

(not furnished)

Do not connect to

valve drain hose.

Hose adapter

Fig. 4

Drain

fitting

on valve

Valve drain hose

FLOOR DRAIN

Tie or wire

hose in place

1

1

⁄

2

″ air gap

LAUNDRY TUB

SUMP

Clamp

STANDPIPE

Blue indicator light

4. CONNECT AND RUN THE VALVE DRAIN HOSE

• Use the provided drain hose (20

′ length included) to attach to the

valve drain fitting. To keep water pressure from blowing the hose off,

use a hose clamp to secure in place. Cut the necessary length and use

the remainder in Step 5.

• Locate the other end of the hose at a suitable drain point (floor drain,

sump, laundry tub, etc.) that terminates at the sewer. Check and comply

with local codes.

IMPORTANT: If more drain hose is needed, it should be ordered from

GE Parts at 800.626.2002. The water softener will not work if water

cannot exit this hose during recharge.

• Tie or wire the hose in place at the drain point. High water pressure will

cause it to whip during the back-wash and fast rinse cycles of recharge.

Also provide an air gap of at least 1

1

⁄

2

″ between the end of the hose and

the drain point.

An air gap prevents possible siphoning of sewer water

into the softener, if the sewer should “back-up.”

• Elevating the drain hose may cause back pressure that could reduce

the brine draw during recharge. If raising the drain line overhead is

required to get to the drain point, measure the inlet water pressure to

the softener first. For inlet pressures between 20 and 50 psi, do not raise

higher than 8

′ above the floor. For inlet pressure above 50 psi, the drain

line may be raised to a maximum height of 14

′.

4A. CONNECTING A RIGID VALVE DRAIN TUBE

To adapt a copper drain tube to the softener, use a hacksaw to cut the

barbed end from the drain fitting as shown in Fig. 4A. Rotate the drain

fitting so the cutting blade clears the valve housing to prevent damage to

valve. Buy a compression fitting (1/4

″ female pipe thread x 1/2″ O.D. tube)

and needed tubing from your local hardware store.

5. INSTALL THE BRINE TANK OVERFLOW FITTINGS AND HOSE

• Insert the rubber grommet into the 3/4

″ diameter hole in the brine

tank sidewall as shown in Fig. 5.

• Push the end of the hose adapter elbow into the grommet as shown

in Fig. 5.

• Attach a length of hose (use remaining hose from Step 4) to the hose

adapter elbow. Use a hose clamp to hold it in place.

• Locate the other end of the hose at the drain point. DO NOT ELEVATE

this hose higher than the elbow on the brine tank.

IMPORTANT: DO NOT TEE OVERFLOW HOSE TO VALVE DRAIN HOSE.

NOTE: This drain is for safety only. If the cabinet (brine tank) should

over-fill with water, the excess is carried to the drain.