Troubleshooting (cont.), Heating problems, Brewing problems – Grindmaster SHUTTLE BREWER APBVSA-430V2E230 User Manual

Page 24

Page 24

Shuttle Brewers & Airpot/Shuttle Brewers

Troubleshooting (cont.)

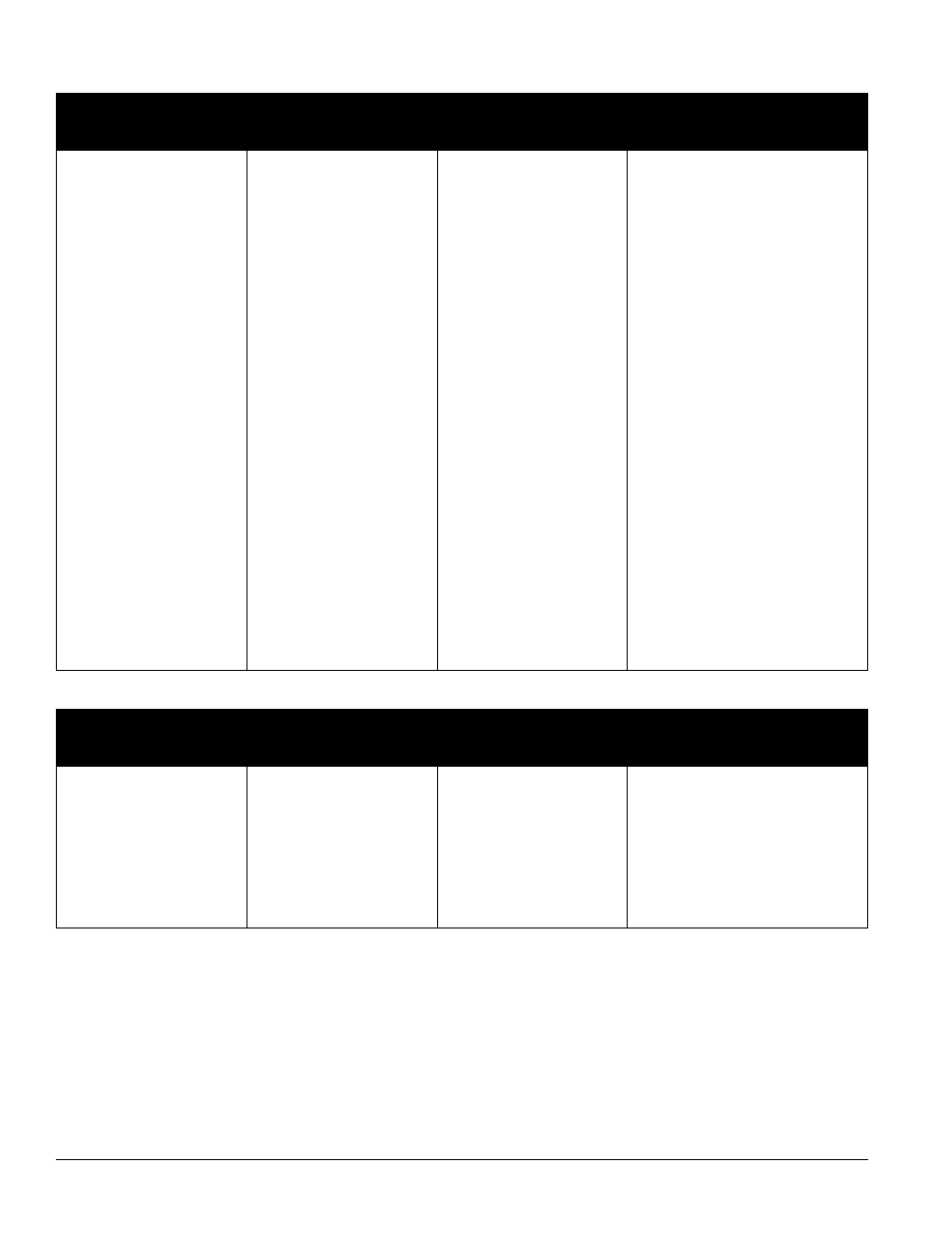

Heating Problems

Problem

Possible Causes

Service Check

Remedy

Tank does not heat

• Contactor faulty.

• Heater faulty.

• Control board is faulty.

• Ensure that coil on

contactor is energized

by ensuring that there

is proper voltage

between the brown and

white wires attached to

the relay. Check each

side of the contactor

(Line and Load) at each

pole for continuity.

• Check resistance

across element(s)

with power conductors

disconnected.

• Check to ensure proper

connection between

connector 5-pin and

control board. Check

for proper connections

in all heater control

circuitry. Check for

proper connections

between N terminal of

contactor coil and

terminal block.

• If the contactor coil is

energized and there is an

open circuit across any of

the contactor poles, replace

contactor.

• If resistance is much less than

8 Ohms or much more than

15 Ohms, replace heater(s).

• If 5-pin connector is securely

attached to control board

and all connections are

secure and functioning

except there is not 120 Vac

across contactor coil terminals,

replace control board.

Brewing Problems

Problem

Possible Causes

Service Check

Remedy

Brew volume too

large or too small

• Portion selected on

touchpad not correct.

• Timer not set properly.

• Review timer settings

versus portion size.

• Compare timer setting

to either factory setting

or initial user setting to

determine if it has

been changed.

• Adjust timer to desired value or

select different portion size.

• Adjust timer to desired value.

- SHUTTLE BREWER APBIC-330V2E230 SHUTTLE BREWER APBIC-430V2 SHUTTLE BREWER APBVSA-330V2 SHUTTLE BREWER APB-430V2 SHUTTLE BREWER APB-330V2 SHUTTLE BREWER APB-430V2E230 SHUTTLE BREWER APBIC-330V2 SHUTTLE BREWER APBIC-430V2E230 SHUTTLE BREWER APBVSA-430V2 SHUTTLE BREWER APBVSA-330V2E230 SHUTTLE BREWER APB-330V2E230