Troubleshooting guide, Problem possible cause solution – Grindmaster 3341A User Manual

Page 17

Crathco

®

Remote Beverage Freezers

Page 15

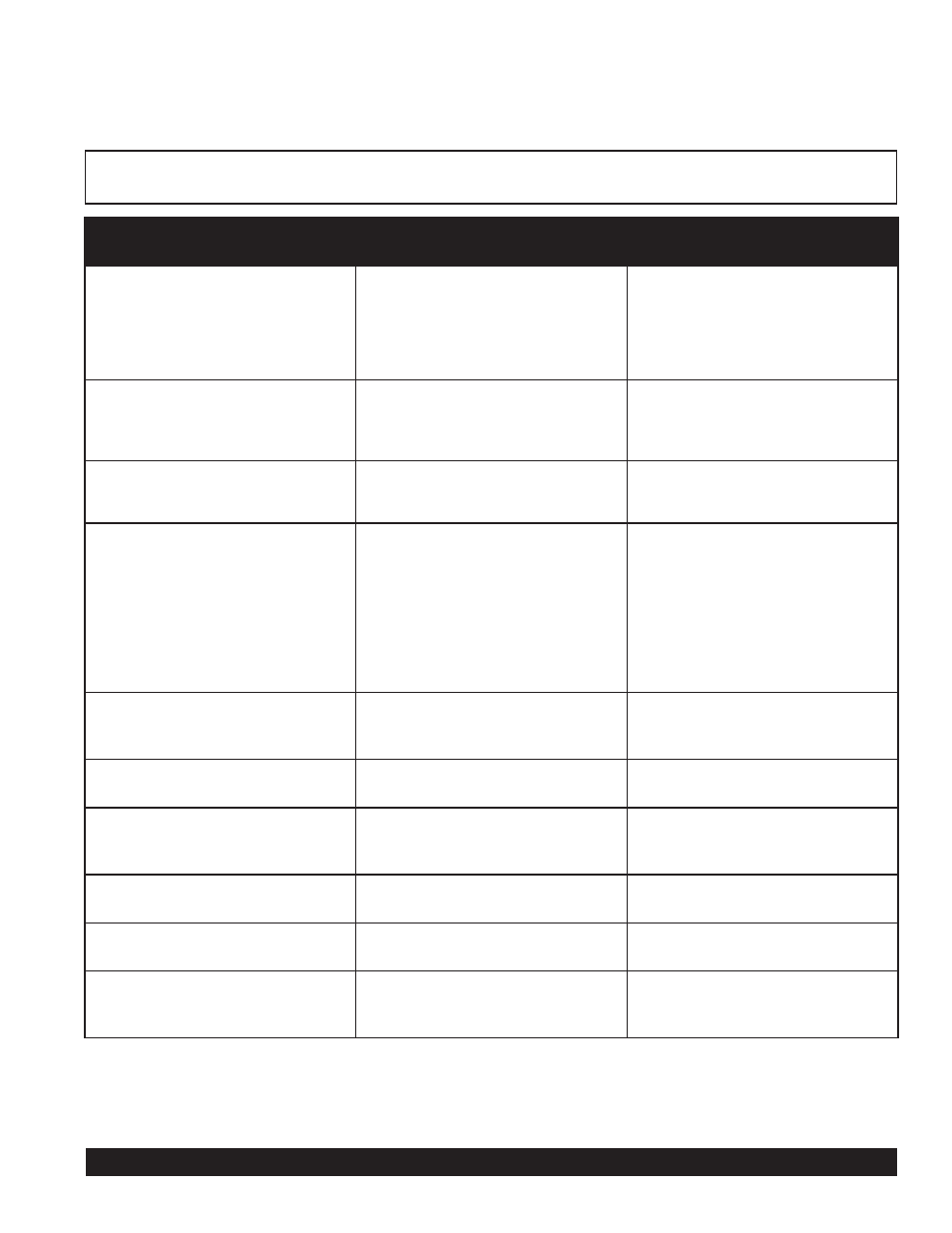

TROUBLESHOOTING GUIDE

Freezer problems can originate from three sources: improper operation, mix problems or

mechanical malfunction. Always check first for improper operation and mix problems before

calling a service technician.

Caution:

Always disconnect power before attempting any maintenance procedures.

Only a qualified service technician should perform electrical and mechanical adjustments or repairs.

ƽ

Problem

Possible Cause

Solution

Machine will not run or freeze down

• Machine not plugged in

• Circuit breaker tripped or fuse blown

• Machine in "CLEAN" or “OFF” position

• Dasher or scraper blades not installed

• Sequencer failure

• Low refrigerant

• Plug in machine

• Reset circuit breaker or replace fuse

• Turn switch to “ON” position

• Install dasher assembly

• Replace

• Check for leaks

Product too soft

• Consistency setting too loose

• Product BRIX level too high

• Consistency setting at maximum

(red spring)

• Re-adjust consistency setting

• Lower liquid product BRIX level

• Change to yellow spring

Product too stiff

• Consistency adjuster set too firm

• Product BRIX level too low

• Re-adjust consistency setting or change

to red spring

• Increase product BRIX level

Product will not dispense

• Power switch “OFF”

• Inadequate mix in hopper Red

MIX LOW light on.

• Consistency set too firm

• Carburetor inlet hole clogged

• Drive belt broken or off pulley

• Drive shaft worn

• Drive motor failure

• Turn power switch “ON”

• Refill hopper

• Readjust consistency setting

• Unclog carburetor inlet hole

• Repair and replace

• Inspect square drive shaft pocket

for excessive wear, replace

• Replace motor

Leakage from drip tube,

front of freezer

• Worn out or defective drive shaft seal

• Seal installed incorrectly

• Replace seal and then lubricate

at each cleaning

• Remove and re-install seal

Excessive dispensing

valve leakage

• Worn or defective O-Ring(s)

• Replace and lubricate

Clicking sound from inside

machine

• Low voltage extension cord

being used

• Use dedicated circuit with

proper rating

• Connect directly to power source

Merchandiser light flickers or goes

out when compressor starts

• Low voltage

• Use dedicated circuit with

proper rating

Thumping sound from inside

machine

• Worn belt

• Worn scraper blades

• Replace belt

• Replace scraper blades

Premature seal wear

• Incorrect installation of dasher

• Improper drive shaft clearance

• Incorrect shaft alignment

• Advise careful installation

• Adjust to proper clearance

• Align shaft

if you still need help, call our service department at (800) 695-4500 (USA & Canada only) or (502) 425-4776 Monday

through Friday, 8 am – 6 pm EST or an authorized service center in your area. Please have the model and serial numbers

ready so that accurate information may be given.

Prior authorization must be obtained from Grindmaster Corporation Technical Services Department for all warranty claims.