Belt drive b – Goodman Mfg IO-367B User Manual

Page 12

12

System Voltage - That nominal voltage value assigned to a

circuit or system for the purpose of designating its voltage

class.

Nameplate Voltage - That voltage assigned to a piece of

equipment for the purpose of designating its voltage class

and for the purpose of defining the minimum and maximum

voltage at which the equipment will operate.

Utilization Voltage - The voltage of the line terminals of the

equipment at which the equipment must give fully satisfac-

tory performance. Once it is established that supply voltage

will be maintained within the utilization range under all sys-

tem conditions, check and calculate if an unbalanced condi-

tion exists between phases. Calculate percent voltage un-

balance as follows:

Three Phase Models Only

3) PERCENT VOLTAGE

UNBALANCE

2) MAXIMUM VOLTAGE DEVIATIONS

FROM AVERAGE VOLTAGE

1) AVERAGE VOLTAGE

HOW TO USE THE FORMULA:

EXAMPLE: With voltage of 220, 216, and 213

1) Average Voltage = 220+216+213=649 / 3 = 216

2) Maximum Voltage Deviations from Average Voltage = 220 - 216 = 4

3) Percent Voltage Unbalance = 100 x

=

= 1.8%

Percent voltage unbalance MUST NOT exceed 2%

.

4

216

400

216

= 100 X

F

IELD

D

UCT

C

ONNECTIONS

Verify that all duct connections are tight and that there is no

air bypass between supply and return.

F

ILTER

S

ECTION

C

HECK

Remove filter section access panels and check that filters

are properly installed. Note airflow arrows on filter frames.

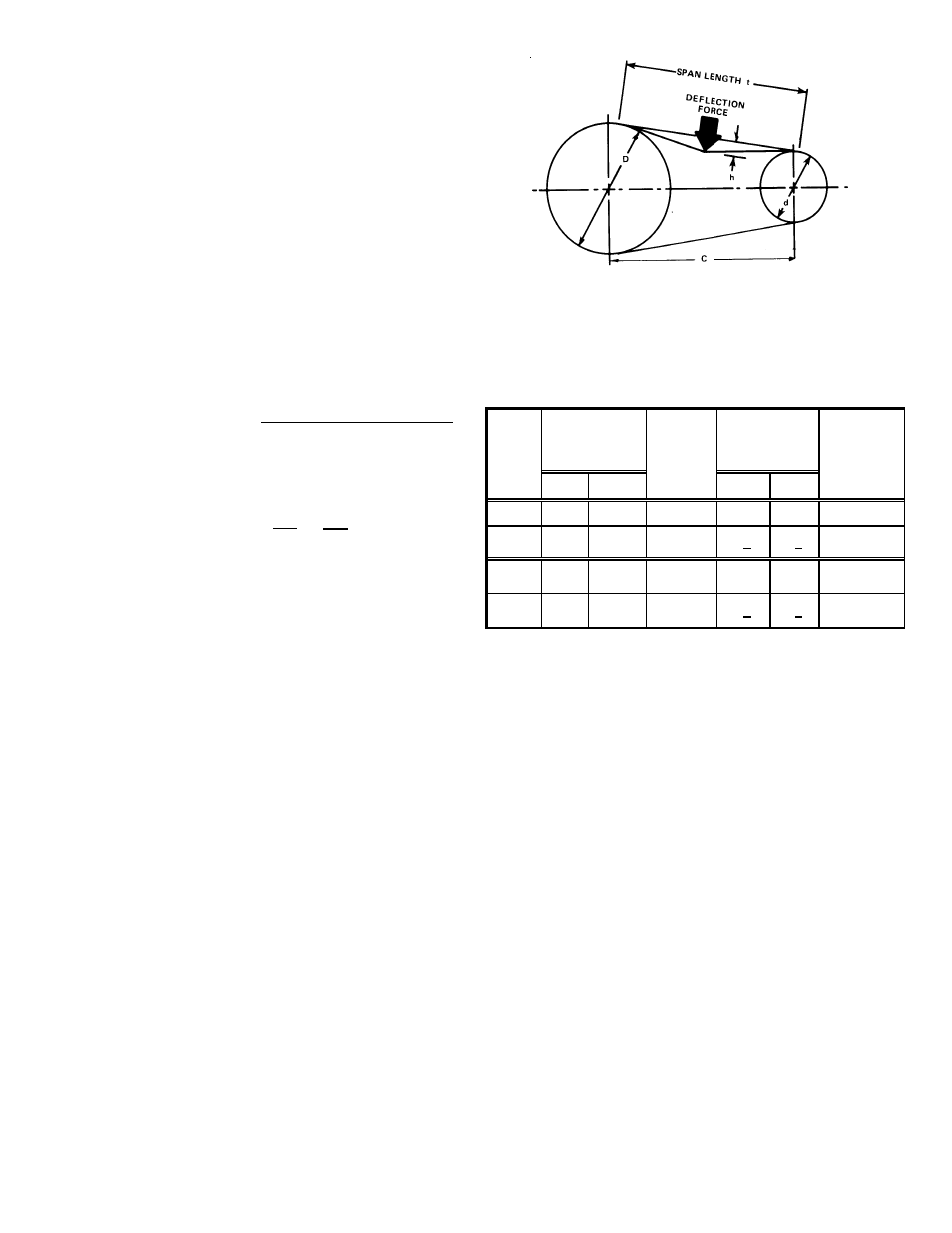

BELT DRIVE

B

EARING

C

HECK

Prior to energizing any fans, check and make sure that all

setscrews are tight so that bearings are properly secured to

shafts.

For heat pump units, the airflow must be adjusted so that the

air temperature rise falls within the ranges given stated on

Data Plate (see Appendix A - Blower Performance).

NOTE: Section on high static tables may require a field motor

change.

T

ENSION

AND

A

LIGNMENT

A

DJUSTMENT

Correct belt tension is very important to the life of your belt.

Too loose a belt will shorten its life; too tight, premature mo-

tor and bearing failure will occur. Check you belt drive for

adequate “run-in” belt tension by measuring the force required

to deflect the belt at the midpoint of the span length. Belt

tension force can be measured using a belt tension gauge,

available through most belt drive manufacturers.

t = Span length, inches

C = Center distance, inches

D = Larger sheave diameter, inches

d = Smaller sheave diameter, inches

h = Deflection height, inches

DRIVE BELT TENSION ADJUSTMENT

BELT

DRIVE

Used

New

15 Ton

B, BX Standard

4.3 to 5.5

5.5 + .5 8.2 + .5

1/4 ± 1/16

15 Ton

B, BX

High

Static

4.3 to 5.5

5.5 + .5 8.2 + .5

1/4 ± 1/16

20 Ton

B, BA Standard

4.3 to 5.5

5.5 + .5 8.2 + .5

1/4 ± 1/16

20 Ton

B, BA

High

Static

4.3 to 5.5

5.5 + .5 8.2 + .5

1/4 ± 1/16

MODEL

DEFLECTION

(in)

DEFLECTION

FORCE (lbs)

SHEAVE

DIAMETER

(in)

TYPE

RECOMMENDED POUNDS OF FORCE PER BELT

New V-belts will drop rapidly during the first few hours of use.

Check tension frequently during the first 24 hours of opera-

tion. Tension should fall between the minimum and maximum

force. To determine the deflection distance from a normal

position, measure the distance from sheave to sheave using

a straightedge or a cord. This is your reference line. On mul-

tiple belt drives, an adjacent undeflected belt can be used as

a reference.

E

VAPORATOR

F

AN

R

OTATION

C

HECK

(T

HREE

P

HASE

M

ODELS

O

NLY

)

Check that fan rotates clockwise when viewed from the drive

side of unit and in accordance with rotation arrow shown on

blower housing. If it does not, reverse the two incoming power

cables at Single Point Power Block. In this case, repeat bear-

ing check.

Do not attempt to change load side wiring. Internal wiring

assures all motors and compressors will rotate in correct di-

rection once evaporator fan motor rotation check has been

made.

E

LECTRICAL

I

NPUT

C

HECK

Make preliminary check of evaporator fan ampere draw and

verify that motor nameplate amps are not exceeded. A final

check of amp draw should be made upon completion of air

balancing of the duct system (see Appendix C).