Grizzly G0516 User Manual

Page 33

G0516 Lathe/Mill

-31-

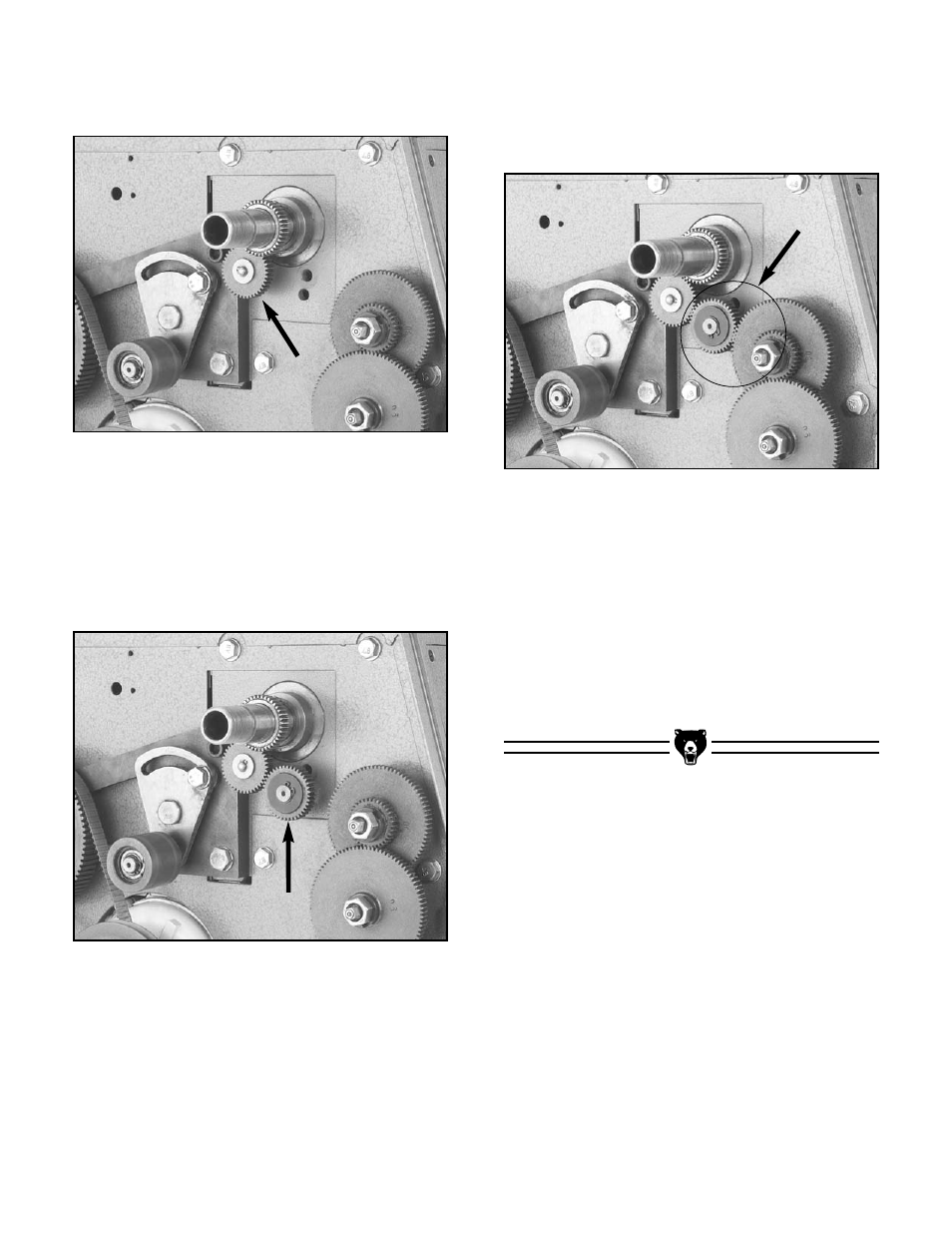

Figure 46. Extra fixed-shaft gear mounted in

position “A.”

Figure 47. Fixed-shaft gear mounted in

position “B.”

3.

Thread the extra fixed-shaft gear into mount-

ing location “A” as shown in

Figure 46.

4.

When the machine is shipped, a fixed-shaft

gear is in position “C.” Remove that fixed-

shaft gear from mounting location “C” and

thread it into mounting location “B” as shown

in

Figure 47.

Figure 48. All gears in mesh for reverse

threading operations.

5.

Loosen the cap screw on the gear bracket,

and pivot the bracket so the top gear mesh-

es with the fixed-shaft gear that is in position

“B,” as shown in

Figure 48.

6.

Tighten the cap screw in the gear bracket to

keep it from pivoting.

7.

Spin the lathe chuck by hand to ensure that

the gears do not bind.

8.

Replace the cover and test run the machine

before proceeding with your specific opera-

tion.

- H7670 (20 pages)

- H7792 (20 pages)

- H7947 (24 pages)

- G7958 (16 pages)

- G1007 (52 pages)

- G9861 (56 pages)

- G9861 (56 pages)

- Extreme Series Jointer G9860 (76 pages)

- H6331 (20 pages)

- G4179 (32 pages)

- G0500 (71 pages)

- T10446 (16 pages)

- G0463 (40 pages)

- H6143 (20 pages)

- G8125 (2 pages)

- H0800 (6 pages)

- POWER FEED H8370 (4 pages)

- H8116 (20 pages)

- G4003 (55 pages)

- G7948 (2 pages)

- T10010 (28 pages)

- H7668 (24 pages)

- Extren Series Jointer g9860 (76 pages)

- Panther 5 Shelf Unit T10001 (2 pages)

- 28 clipped head framing nailer h6145 (20 pages)

- G1021Z (39 pages)

- H7949 (32 pages)

- Extreme Duty Planners G9740 (76 pages)

- G4008 (26 pages)

- H8154 (1 page)

- 3/8" Impact Wrench w/ Front Exhaust H8119 (2 pages)

- Model H8222 (16 pages)

- G9953ZXF (76 pages)

- COMBINATION SANDER G1183 (48 pages)

- H7758/H7759 (28 pages)

- Extreme-Duty s G9740 (76 pages)

- G2790 (23 pages)

- G0633/G0634 (72 pages)

- G1006 (23 pages)

- Flex Shaft G9928 (12 pages)

- G0456 (48 pages)

- H8170/H8171 (32 pages)

- H7943/H7944 (24 pages)

- H0777 (10 pages)

- 5 GALLON AUTOMATIC MIXING PAINT TANK H8226 (16 pages)