Dust collector operation – Grizzly G0710 User Manual

Page 28

-26-

Model g0710/g0710p (Mfg. since 11/11)

dust collector operation

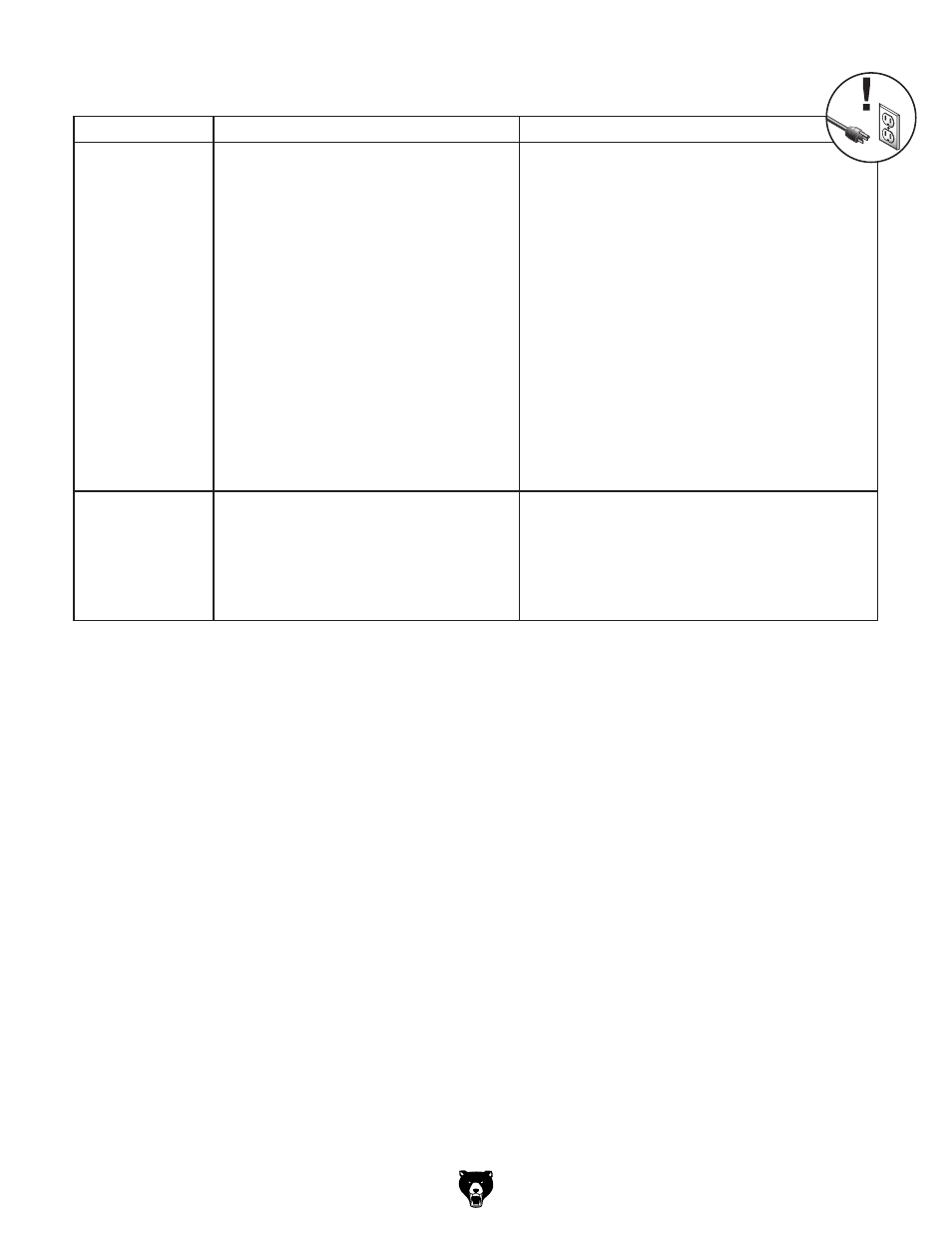

symptom

possible Cause

possible solution

dust collector does

not adequately

collect dust

or chips; poor

performance.

1. dust collection bag is full.

2. restriction in duct line.

3. the dust collector is too far away, or there

are too many sharp bends in the ducting.

4. the lumber is wet and dust is not flowing

through the ducting smoothly.

5. leaks in ducting or too many open ports.

6. ducting and or machine dust ports are

incorrectly sized.

7. the machine dust collection design is

inadequate.

8. the dust collector is too small for the

task or machine.

1. empty collection bag.

2. remove dust line from dust collector inlet and

unblock the restriction in the duct line. a plumbing

snake may be necessary.

3. relocate the dust collector closer to the point of

suction, and rework ducting without sharp bends.

refer to

collection system, beginning on page

16.

4. process lumber with less than 20% moisture

content.

5. rework the ducting to eliminate all leaks. Close

dust ports for lines not being used.

6. re-install correctly sized ducts and fittings. refer

to

collection system beginning on page 16 for

more solutions.

7. use a dust collection nozzle on a stand.

8. use a larger dust collector.

sawdust being

blown into the

air from the dust

collector.

1. duct clamps or dust collection bag is not

properly clamped and secured.

2. Bag clamp is loose or damaged.

3. dust is extremely fine.

1. re-secure ducts and dust collection bag, making

sure duct and bag clamps are tight and completely

over the ducts and bag.

2. re-tighten bag clamp.

3. replace filter bag with grizzly Model h4340 3.0

micron type. install one or more grizzly Model

g0572 hanging air Filters.