Collection system – Grizzly G0710 User Manual

Page 18

-16-

Model g0710/g0710p (Mfg. since 11/11)

material selection

you have many choices regarding dust collection

ducting, but flexible hose is the most common for

this size of machine. however, be aware that there

is a fire or explosion hazard if plastic duct material

is used for dust collection without being grounded

against static electrical charge build-up.

Flexible rubber hose, polyethylene, plastic flex-

hose and other flexible ribbed hose is gener-

ally used for short runs. there are many different

types of flex hose on the market today. these are

manufactured from materials such as polyethyl-

ene, pVC, cloth hose dipped in rubber and even

metal, including steel and aluminum.

if using flex-hose, you should choose one of the

many types that are designed specifically for

the movement of solid particles, i.e. dust, grains

and plastics. however, the cost of specifically

designed flexible duct can vary greatly. grizzly

offers polyethylene and steel flex hose.

collection system

always guard against

static electrical build up

by grounding all dust

collection lines.

duct grounding

plastic flex-hose is an insulator, and dust particles

moving against the walls of the hose creates a

static electrical build up. this charge will build

until it discharges to a ground. if a grounding

medium is not available to prevent static electrical

build up, the electrical charge will arc to the near-

est grounded source. this electrical discharge

may cause an explosion and subsequent fire

inside the system.

to protect against static electrical build up inside

a non-conducting duct, a bare copper wire should

be placed inside the duct along its length and

grounded to the dust collector. you must also

confirm that the dust collector is continuously

grounded through the electrical circuit to the elec-

tric service panel.

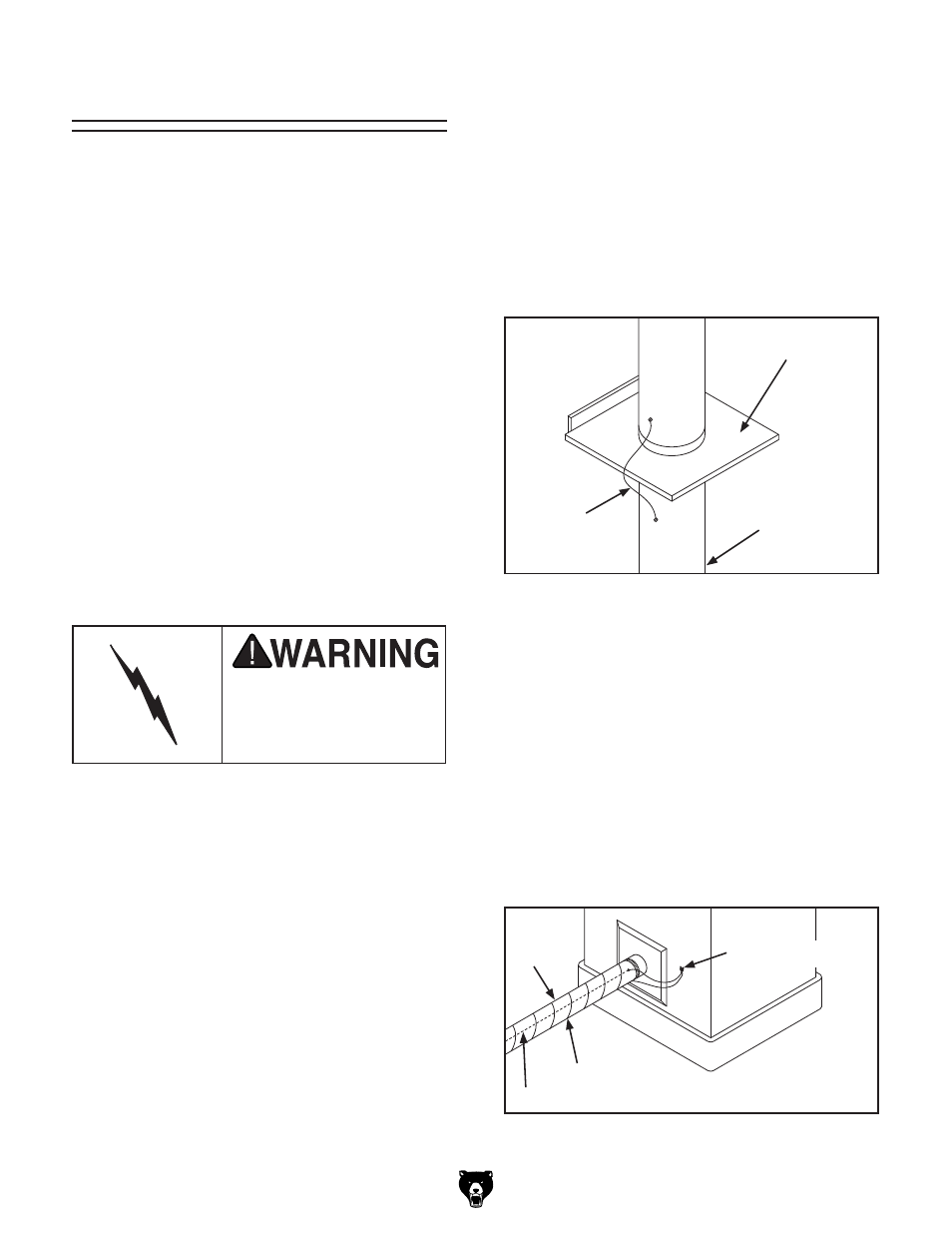

figure 12. ground jumper wire when using

plastic blast gates or elbows and metal duct.

plastic Blast gate

Metal duct

Copper

ground Wire

figure 13. Flex-hose grounded to machine.

ground screw

Flex

hose

internal ground Wire

external ground Wire

Be sure that you extend the bare copper wire

down all branches of the system. do not forget

to connect the wires to each other with wire nuts

when two branches meet at a “y” or “t” connec-

tion.

ensure that the entire system is grounded. if

using plastic blast gates to direct air flow, the

grounding wire must be jumped (see

figure 12)

around the blast gate without interruption to the

grounding system.

We also recommend wrapping the outside of all

plastic ducts with bare copper wire to ground the

outside of the system against static electrical build

up. Wire connections at y’s and t’s should be

made with wire nuts.

attach the bare ground wire to each stationary

woodworking machine and attach the dust collec-

tor frame with a ground screw as shown in

figure

13. ensure that each machine is continuously

grounded to the grounding terminal in your elec-

tric service panel.