Workpiece inspection, Routing – Grizzly G0528 User Manual

Page 23

model g0528 (mfg. 5/04+)

-21-

Workpiece

inspection

Some workpieces are not safe to cut or may

require modification before routing.

Before rout-

ing, inspect all workpieces for the following:

•

Material Type

this machine is intended for cutting natural

and man-made wood products, laminate cov-

ered wood products, and some plastics. this

machine is not designed to cut metal, glass,

stone, tile, etc.

•

Foreign Objects

nails, staples, dirt, rocks and other foreign

objects are often embedded in wood. While

shaping, these objects can become dis-

lodged and hit the operator, cause kickback,

or break the blade, which might then fly apart.

always visually inspect your workpiece for

these items. if they can't be removed, do

not cut the workpiece.

•

Large/Loose Knots

loose knots may dislodge during a cutting

operation. Knots can cause kickback and

machine damage. Choose workpieces that

do not have large/loose knots or plan ahead

to avoid shaping through them.

•

Wet or "Green" Stock

Shaping wood with a moisture content over

20% causes unnecessary wear on the cut-

ters, increases the risk of kickback, and

yields poor results.

•

Excessive Warping

Workpieces with excessive cupping, bowing,

or twisting are dangerous to cut because they

are unstable and often unpredictable when

being shaped. do not process workpieces

with these characteristics!

•

Minor Warping

Workpieces with slight cupping can be safe-

ly supported if the cupped side is facing

the table or the fence. on the contrary, a

workpiece supported on the bowed side will

rock during a cut and could cause kickback or

severe injury.

routing operations on your model g0528 are

grouped into three main techniques:

• edge Jointing

• groove Cutting

• profile Cutting

Edge Jointing

Jointing the edge of a board involves using a

straight cutting router bit to remove wood from the

edge face of a board. the result is a perfectly flat

and square edge.

To joint the edge of a workpiece:

1. Secure a straight cutting router bit into your

router according to the router manufacturer’s

instructions.

2. Snap the smallest table insert into the

recessed hole that still allows the router bit to

freely rotate.

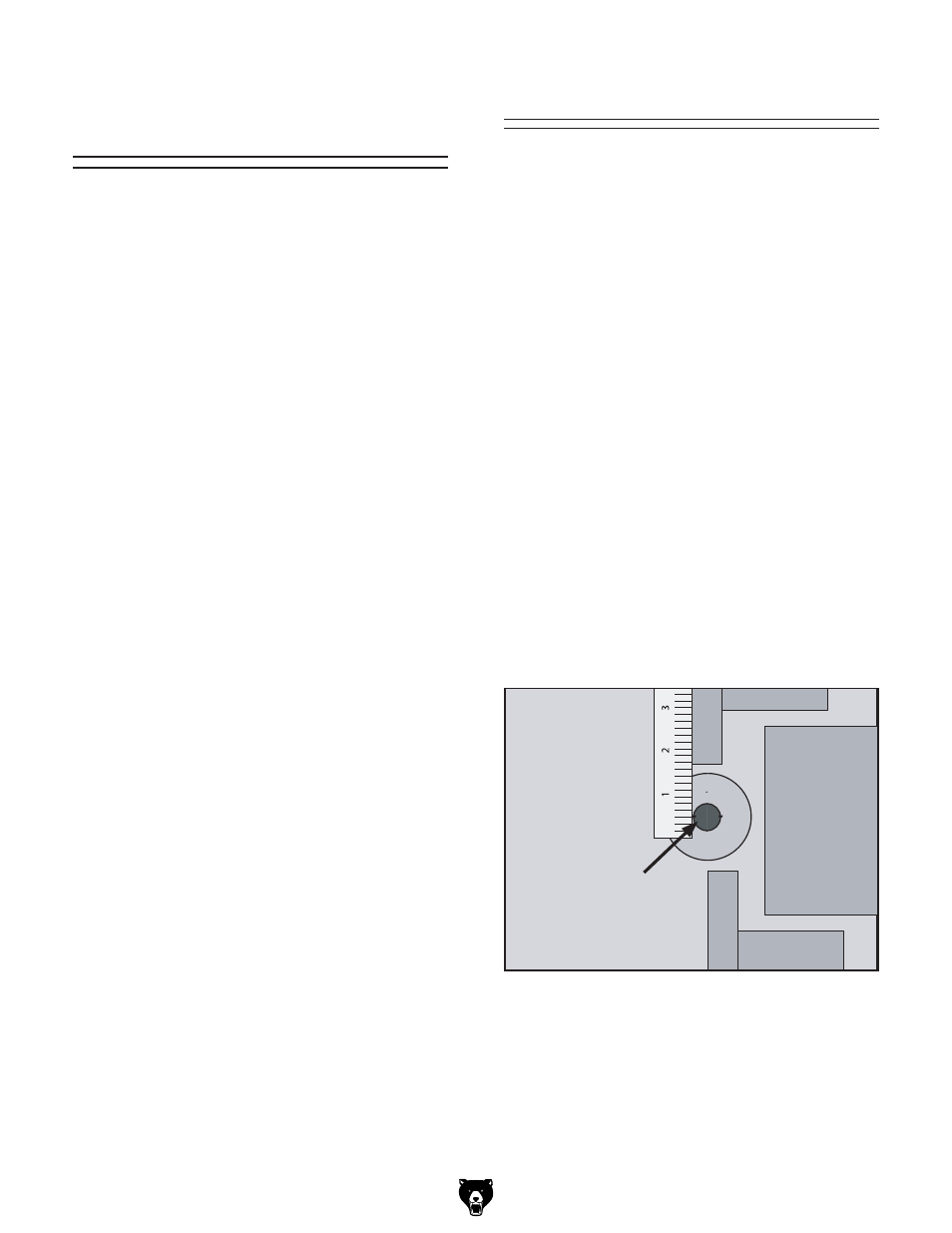

3. adjust the outfeed fence even with the left

edge of the router bit (

figure 20).

figure 20. Jointing setup

(top view).

Routing