Grindmaster PM45-B User Manual

Page 8

Page 8

Crathco

®

Post Mix Beverage Dispensers

Washing Parts (cont.)

2.

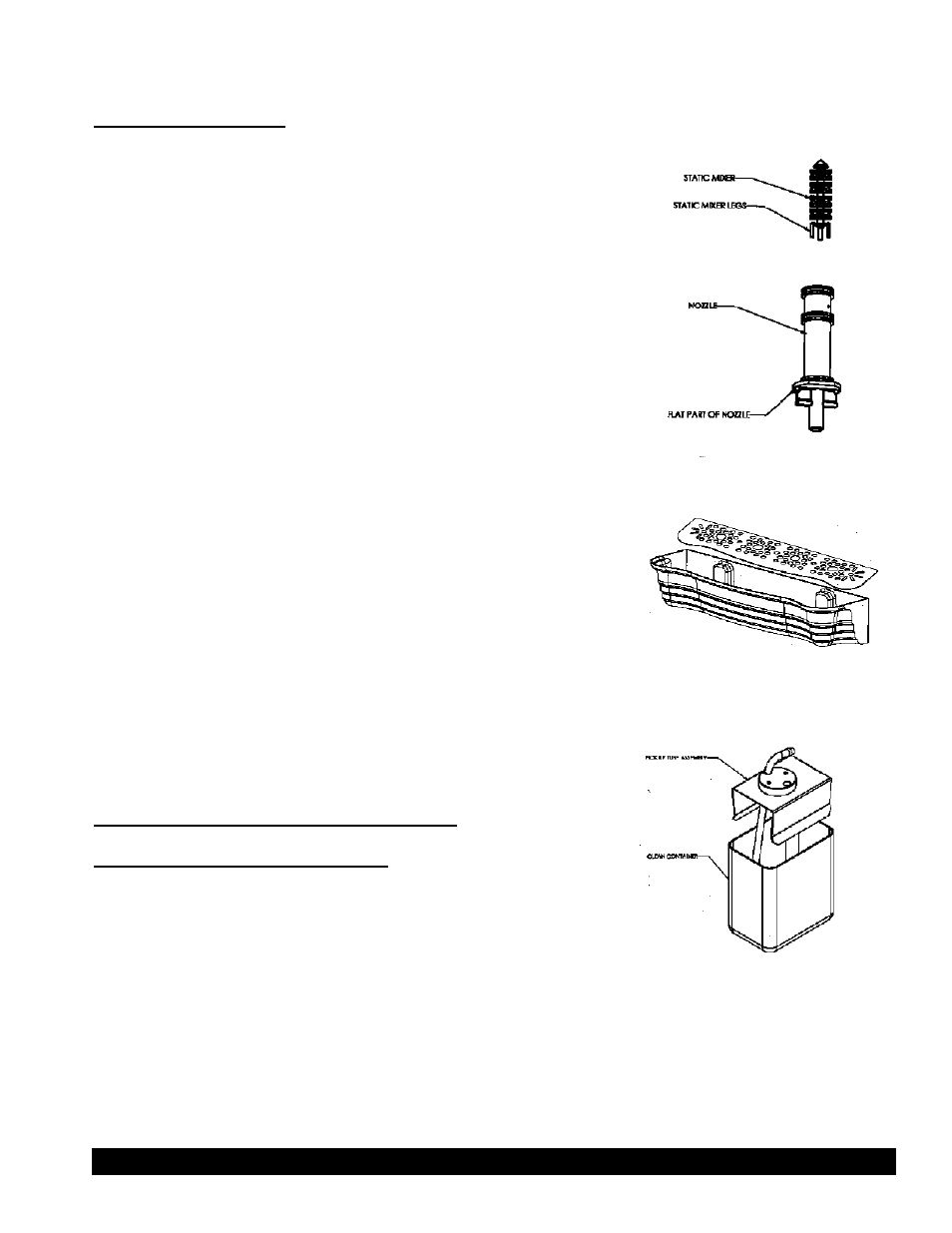

Remove the dispensing nozzle from the machine by turning it 90

°

to the

left or right side, pulling it down. If

there is a

problem pulling it down, turn the nozzle with quick short left to right and

back motions pulling it

down at the same time. Make

sure that the nozzle is in the proper position. The flat part of the thin round

plate should be between

screw heads. Remove product pick up tubes from the product containers.

Note: Static mixer is inside the nozzle. If static mixer is lost, the product will not

mix properly. (See Figure F.)

3.

Turn the dispensing nozzle upside down and remove static mixer.

Repeat the same with all remaining nozzles.

4.

Wash the parts with water mixed with hand dishwashing detergent.

5.

Rinse all parts thoroughly, put static mixers into nozzle leg first and

install them back in the machine by inserting

into mixing chambers and

locking

in positions. Failing to lock in position may cause dispensing nozzle with the

static mixer to be pushed rapidly out of the mixing chamber by the

29

Psig

(2

bar)

water

pressure and splash all surrounding with

mixed product. Replace product pick up

tubes.

Note: Wash on a regular basis the drip tray and the drip tray grill separate-

ly. (see figure G)

Sanitizing and Cleaning Dispensing System

Product Pumps System Cleaning

The product pumps system cleaning assures the performance of the pump-

ing system and cleans the inside walls of tubing.

The product used is very thick (6+1 concentration or more) and will build up

a layer of sucrose and pulp mixture on the inside walls of tubing. This build up

narrows the inside diameter of the tubes and will restrict the product flow and

will slowly offset the brix. Proper cleaning of the pump system will help prevent and correct this condition.

1.

Remove the product containers from the dispensing cabinet. Replace each container with any clean contain-

er (same capacity as product container) filled with warm water (40-45

°

C) and insert product pick up tubes

(Figure F)

(Figure G)

- - - -

(Figure H)