Service, Warning, Caution – Graco Inc. 308287 User Manual

Page 9: Replacing the turbine alternator

9

308–287

Service

WARNING

Installing and servicing this equipment requires

access to parts that may cause electric shock or

other serious injury if the work is not performed

properly. Do not install or service this equipment

unless you are trained and qualified.

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 6.

NOTE: Check all possible remedies in the Trouble-

shooting section before disassembling the meter.

1.

Relieve the pressure and flush the meter as

described on page 7.

2.

Disconnect the fiber optic cable(s) (G) from the

electronic module (B). See Fig. 3.

3.

Disconnect the air hose fitting and remove the air

hose from the motor. Disconnect both fluid hose

fittings and remove the fluid hose from the meter.

4.

Remove the four screws (A) to separate the gear

housing (F) from the manifold.

CAUTION

Never remove the electronic module (B) from the top

gear housing (E). The electronic module is calibrated

to the gear housing assembly and will not function

properly if removed.

Fig. 3

G

B

E

F

A

C*

Torque to 7.5

ft-lb (10 N

S

m)

D

01851

KEY

A

Screw

B

Electronic Module

C

O-Ring

D

Manifold

E

Top Gear Housing

F

Gear Housing Assy.

G

Fiber Optic Cable

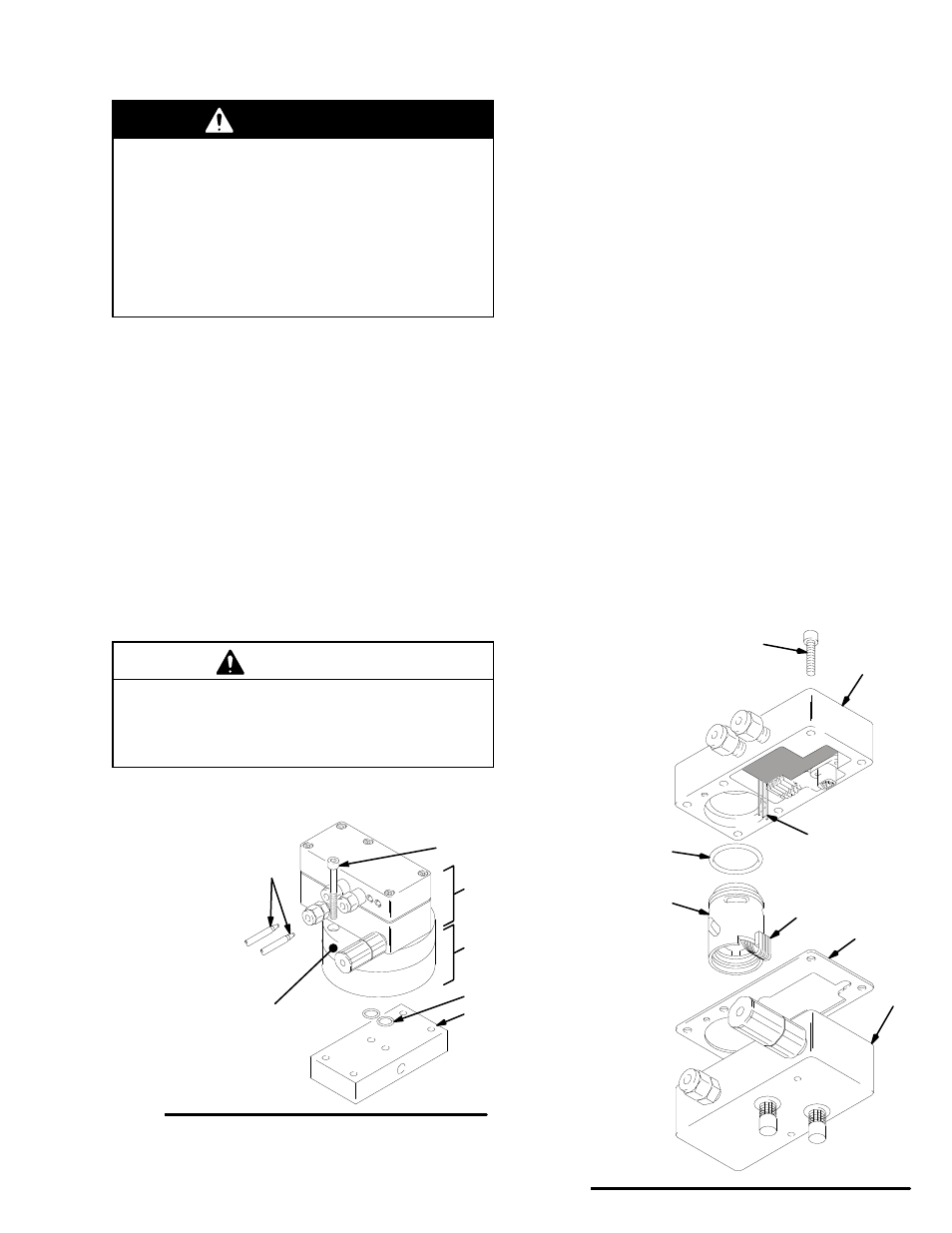

Replacing the Turbine Alternator

1.

Remove the top chassis (3) from the bottom

chassis (2). See Fig. 4.

2.

Disconnect the 3-pin connector (J) from the square

pins (H).

3.

Carefully pull the alternator (4) away from the top

housing.

4.

Using an ohmmeter, test the coil in the turbine

alternator. Measure the resistance between the

two outer terminals of the 3-pin connector (J). The

resistance should be 3–5 ohms. If the reading

varies from this value, replace the alternator (4).

5.

Lubricate the alternator o-ring (4a) seal with petro-

leum jelly.

6.

Insert the alternator (4) into the top chassis (3).

7.

Connect the 3-pin connector (J) to the 3 square

pins (H) in the top chassis (3).

8.

Check to see that the gasket (5) is not damaged. If

damaged, replace the gasket.

9.

Snap the top and bottom chassis together.

10. Install and tighten the chassis screws (9) to 40

in-lbs (4.52 N

S

m).

Fig. 4

3

2

J

H

4

4a

5

9

0180A

KEY

H

Pins

J

3-pin Connector

2

Bottom Chassis

3

Top Chassis

4

Alternator

4a Alternator O-Ring

5

Gasket

9

Chassis Screws

Torque to

40 in-lb

(4.52 N

S

m)