Electrical information – Greenheck Fan 455924 ERV-522 User Manual

Page 8

8

Energy Recovery Ventilator

Electrical Information

The unit must be electrically grounded in accordance

with the current National Electrical Code, ANSI/NFPA

70. In Canada, use current CSA Standard C22.1,

Canadian Electrical Code, Part 1. In addition, the

installer should be aware of any local ordinances or

electrical company requirements that might apply.

System power wiring must be properly fused and

conform to the local and national electrical codes.

System power wiring is to the unit main disconnect

(door interlocking disconnect switch standard

on most units) or distribution block and must be

compatible with the ratings on the nameplate: supply

power voltage, phase, and amperage (Minimum

Circuit Amps - MCA, Maximum Overcurrent Protection

- MOP). All wiring beyond this point has been done

by the manufacturer and cannot be modified without

affecting the unit’s agency / safety certification.

If field installing an additional disconnect switch, it

is recommended that there is at least four feet of

service room between the switch and system access

panels. When providing or replacing fuses in a fusible

disconnect, use dual element time delay fuses and

size according to the rating plate.

If power supply is desired through bottom of unit, run

the wiring through the curb, cut a hole in the cabinet

bottom, and wire to the disconnect switch. Seal

penetration in cabinet bottom to prevent leakage.

The electric supply to the unit must meet stringent

requirements for the system to operate properly.

Voltage supply and voltage imbalance between

phases should be within the following tolerances.

If the power is not within these voltage tolerances,

contact the power company prior to operating the

system.

Voltage Supply: See voltage use range on the rating

plate. Measure and record each supply leg voltage at

all line disconnect switches. Readings must fall within

the allowable range on the rating plate.

Voltage Imbalance: In a 3-phase system, excessive

voltage imbalance between phases will cause motors

to overheat and eventually fail. Maximum allowable

imbalance is 2%. To determine voltage imbalance,

use recorded voltage measurements in this formula.

Key:

V1, V2, V3 = line voltages as measured

VA (average) = (V1 + V2 + V3) / 3

VD = Line voltage (V1, V2 or V3) that

deviates farthest from average (VA)

Formula: % Voltage Imbalance = [100 x (VA-VD)] / VA

WARNING

To prevent injury or death due to electrocution or

contact with moving parts, lock disconnect switch

open.

CAUTION

If any of the original wire as supplied with the

appliance must be replaced, it must be replaced

with wiring material having a temperature rating of

at least 105ºC.

Most factory supplied electrical components are

prewired. To determine what electrical accessories

require additional field wiring, refer to the unit specific

wiring diagram located on the inside of the unit

control center access door. The low voltage control

circuit is 24 VAC and control wiring should not exceed

0.75 ohms.

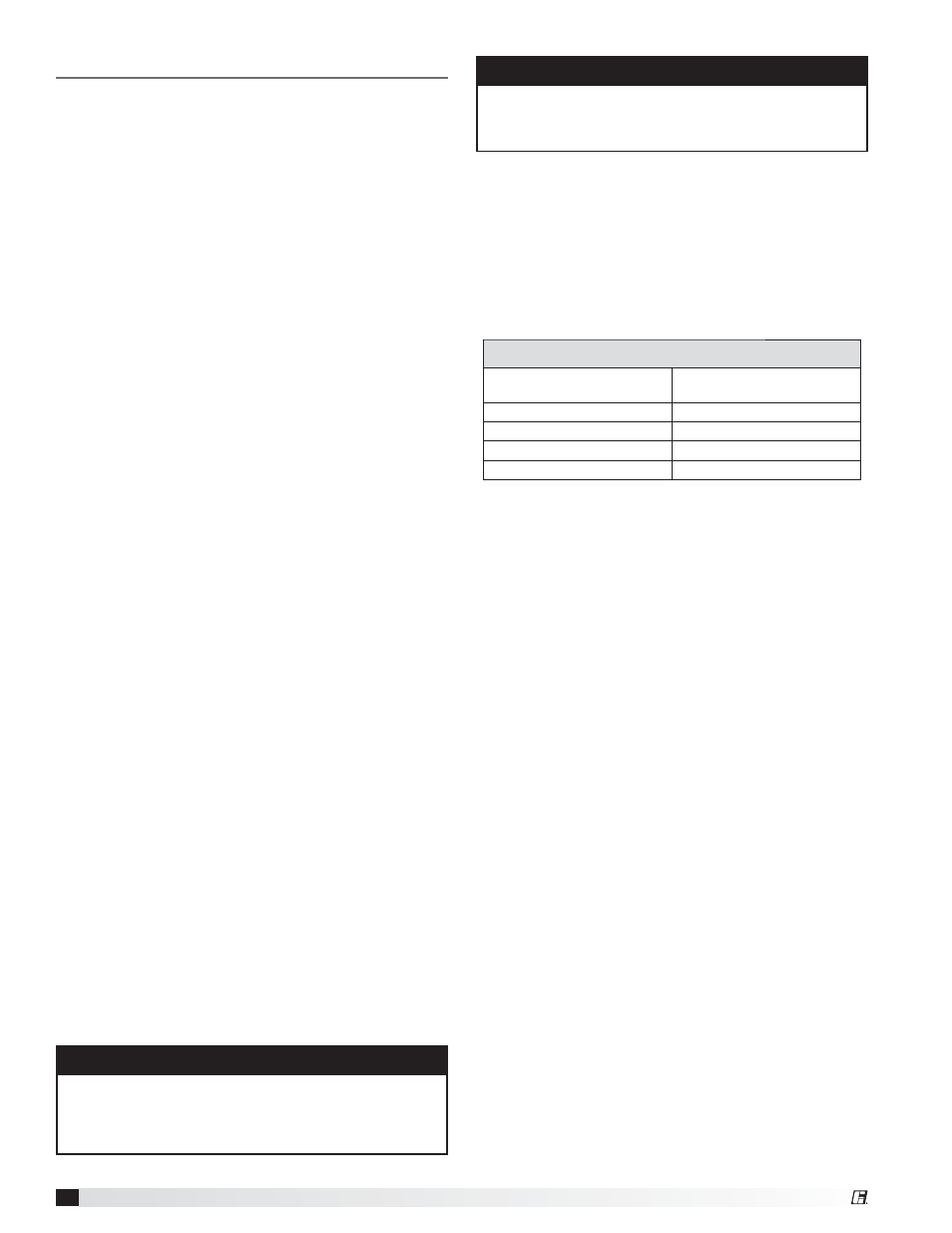

Refer to Field Control Wiring Length/Gauge table for

wire length maximums for a given wire gauge.

Control wires should not be run inside the same

conduit as that carrying the supply power. Make sure

that field supplied conduit does not interfere with

access panel operation.

If wire resistance exceeds 0.75 ohms, an industrial-

style, plug-in relay should be added to the unit

control center and wired in place of the remote

switch (typically between terminal blocks R and G

on the terminal strip (refer to Typical Control Center

Components). The relay must be rated for at least

5 amps and have a 24 VAC coil. Failure to comply

with these guidelines may cause motor starters to

“chatter” or not pull in which can cause contactor

failures and/or motor failures.

Field Control Wiring Length/Gauge

Total

Wire Length

Minimum

Wire Gauge

125 ft.

18

200 ft.

16

300 ft.

14

450 ft.

12