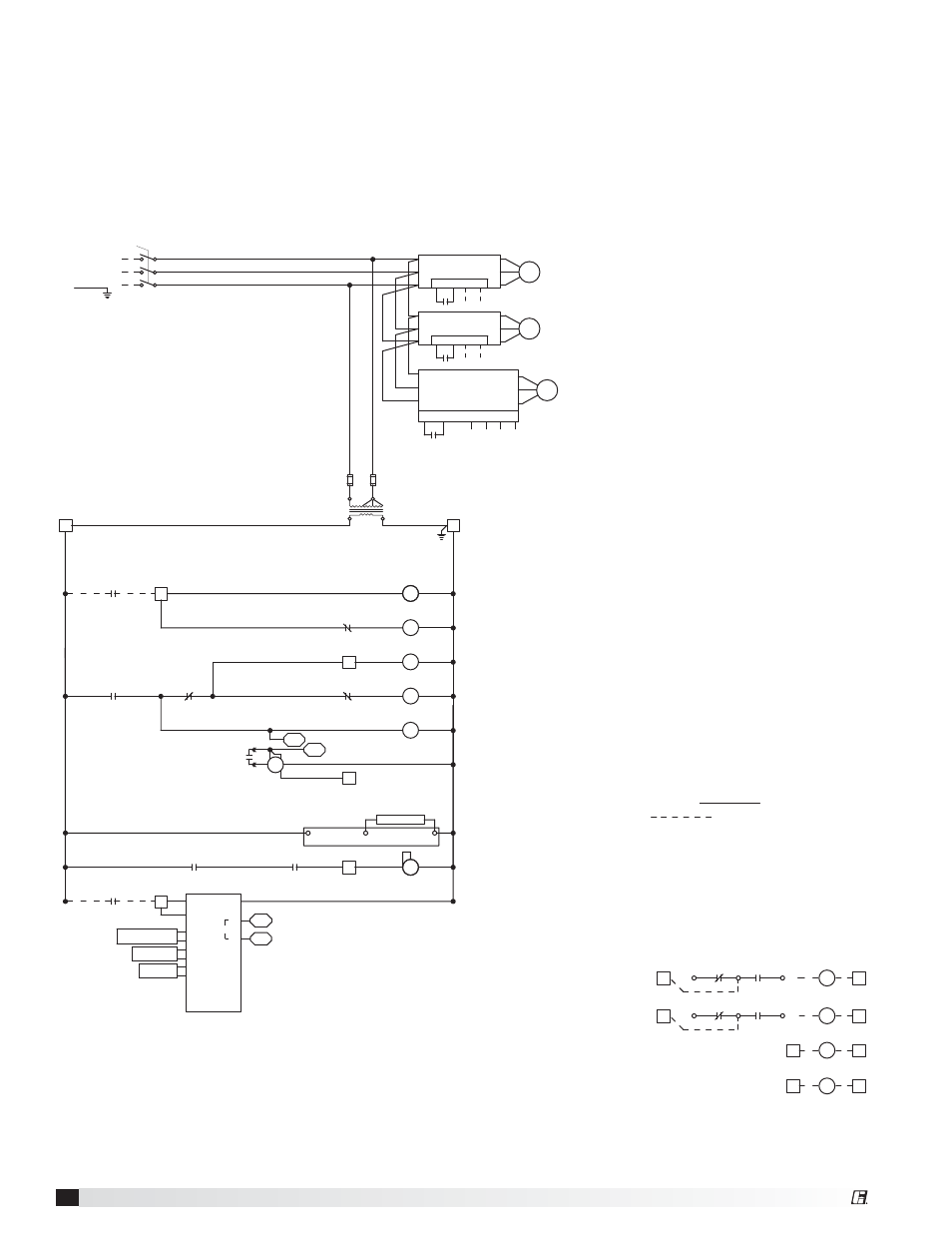

Typical wiring diagram, Energy recovery ventilator – Greenheck Fan 455924 ERV-522 User Manual

Page 18

18

Energy Recovery Ventilator

FACTORY SUPPLIED AND WIRED

G

MULTI-VOLTAGE PRIMARY

24 SECONDARY

TR1

C

FU5

TO UNIT

MAIN POWER

L3

L2

L1

DS1

SUPPLY DAMPER

D2

ENERGY WHEEL

R1

R

TR1

SO

SR

3

FR

FC

2-10V

-

+

1

TR

5

4

2

SR+

RETURN AIR SENSOR

MIXED AIR

SENSOR

T

T1

620 OHM RESISTOR OR

OUTDOOR AIR

SENSOR

SO+

4

S1

VFD-W

L3

3

4

SC

L2

L1

MC

T3

MA

T2

T1

PS1

NO

C

COM

NO

TS1

6

FROST CONTROL

A1

T1

A2

B1

16

15

T1

ENERGY WHEEL

S1

R1

LEGEND

CC COMPRESSOR CONTACTOR

CF CONDENSING FAN CONTACTOR

CH COMPRESSOR SUMP HEATER

D DAMPER

DB POWER DISTRIBUTION BLOCK

DL DAMPER LIMIT SWITCH

DS DISCONNECT SWITCH

EC ECONOMIZER CONTROLLER

FCS CONDENSOR FAN CYCLE SWITCH

FU FUSES

FU5 CONTROL TRANSFORMER FUSES (NOT ON CLASS II)

FZ1 FREEZE PROTECTION

HPS HIGH PRESSURE SWITCH (MANUAL RESET)

LPS LOW PRESSURE SWITCH

PS1 WHEEL FROST PRESSURE SWITCH

PS2 SUPPLY DIRTY FILTER PRESSURE SWITCH

PS3 EXHAUST DIRTY FILTER PRESSURE SWITCH

R1 ENERGY WHEEL RELAY/CONTACTOR

R2 OCCUPIED/UNOCCUPIED RELAY

R3 EXHAUST BLOWER VFD RELAY

R4 SUPPLY BLOWER VFD RELAY

R5 MODULATING WHEEL FROST CONTROL RELAY

R6 ECONOMIZER RELAY

R7 COMPRESSOR INTERLOCK RELAY

R8 EVAP RELAY (INDIRECT)

R9 EVAP RELAY (DIRECT)

R10 UNIT RELAY

S1 FAN SWITCH

S2 ROTATION SENSOR REED SWITCH

S3 ROTATION SENSOR REED SWITCH

S4 CALL FOR HEAT SWITCH

S5 BYPASS SWITCH

S6 CALL FOR COOL SWITCH (FIRST STAGE)

S7 CALL FOR COOL SWITCH (SECOND STAGE)

ST MOTOR STARTER

T1 FROST CONTROL TIMER

TYPICAL SETTINGS t1(OFF) = 5 MIN., t2(ON) = 30 MIN.

T2 ROTATION SENSOR TIMER

T3 ROTATION SENSOR TIMER

T4 ECONOMIZER WHEEL JOG TIMER

TYPICAL SETTINGS t1(OFF) = 3 HRS., t2(ON) = 10 SEC.

T5 EVAP DELAY OFF TIMER

T6 COMPRESSOR MINIMUM OFF TIMER (TYP. 3 MIN.)

T7 COMPRESSOR MINIMUM OFF TIMER (TYP. 3 MIN.)

TR TRANSFORMER

TS1 FROST CONTROL THERMOSTAT (JUMPER - HEAT)

CLOSES ON TEMP. DECREASE TYPICAL SETTING 5º F.

TS2 ECONOMIZER LOW LIMIT THERMOSTAT (JUMPER - HEAT)

OPENS ON TEMP. DECREASE TYP. SETTING 20º OFFSET OR 50ºF.

TS3 ECONOMIZER UPPER LIMIT THERMOSTAT (JUMPER - HEAT)

CLOSES ON TEMP. DECREASE TYP. SETTING 65º F./2º DIFF.

TS4 ROOM OVERRIDE SENSOR

TS5 INLET AIR POST HEATER LOCKOUT THERMOSTAT (AFTER WHEEL)

CLOSES ON TEMP. DECREASE TYPICAL SETTING 65º F.

TS6 INLET AIR COMPRESSOR LOCKOUT THERMOSTAT (JUMPER-HEAT)

OPENS ON TEMP. DECREASE TYPICAL SETTING 60º F./2º DIFF.

A2

A1

o FIELD WIRED

FIELD CONTROL WIRING RESISTANCE SHOULD NOT EXCEED 0.75 OHM. IF

RESISTANCE EXCEEDS 0.75 OHM THEN CONSULT FACTORY. USE 14 GAUGE

MINIMUM WIRE THICKNESS FOR CONTROL WIRING.

REPLACEMENT FUSES: MUST HAVE A MINIMUM I.R. RATING OF 5 KA

CAUTION:

UNIT SHALL BE GROUND IN ACCORDANCE WITH N.E.C.

POWER MUST BE OFF WHILE SERVICING.

USER INTERFACE CONNECTIONS:

*

*

*

*

*

*

o

*

*

*

*

*

*

*

*

D1

EXHAUST DAMPER

GROUND

FR

FC

C

R

C

R

FROST CONTROL INDICATOR

6

C

12

C

ROTATION INDICATOR

DIRTY FILTER INDICATOR SHOWN AS 24V POWER FROM UNIT.

SUPPLY DIRTY

FILTER SWITCH

EXHAUST DIRTY

FILTER SWITCH

DIRTY FILTER INDICATOR SHOWN AS 24V POWER FROM UNIT.

USER INTERFACE CONNECTIONS:

USER INTERFACE CONNECTIONS:

USER INTERFACE CONNECTIONS:

USER TO VERIFY THAT TR1 CAN HANDLE THE VA LOAD OF INDICATOR DEVICES.

USER TO VERIFY THAT TR1 CAN HANDLE THE VA LOAD OF INDICATOR DEVICES.

USER TO VERIFY THAT TR1 CAN HANDLE THE VA LOAD OF INDICATOR DEVICES.

USER TO VERIFY THAT TR1 CAN HANDLE THE VA LOAD OF INDICATOR DEVICES.

TO FR AND FC

ON VFD-W

SEE BELOW FOR

TERMINAL CONNECTIONS

C

NC

NO

NC

C

NO

ECONOMIZER CONTROL

S6

Y1

MOTOR

MOTOR

EXHAUST FAN

SUPPLY FAN

SC

R4

R3

1

L1

L3

L2

S1

1

0-10 VDC

0-10 VDC

3

FR

VFD-S

3

FC

T1

T3

T2

SC

L1

L3

L2

S1

FR

VFD-E

FC

T1

T3

T2

VFD-E O.L.

MB

MC

R3

2

7

EXHAUST FAN

VFD-S O.L.

MB

MC

R4

2

7

SUPPLY FAN

6

R3

8

*

*

6

2

NC

S2

1

T2

C

12

MC

ROTATION SENSOR

MA

ON VFD-W

TO MA AND MC

*

EC

THERMOSTAT(S) TS1,

24 VAC

THERMOSTAT CONTROLLER(S)

OA-SENSOR

SENSOR

COM

o

PS2

PS3

Typical Wiring Diagram

Following is an example of a typical wiring diagram located in the unit control center. This wiring diagram

includes a legend highlighting which accessories were provided with the unit. Factory wiring and field wiring

are also indicated. This particular example includes 1) variable frequency drives on the blowers requiring a

modulating input, 2) modulating energy recovery wheel with factory controls for economizer, 3) energy recovery

wheel rotation sensor, 4) outdoor air and exhaust air dirty filter switches, 5) motorized outdoor air and exhaust

air intake dampers, and 6) timed exhaust frost control. Many other factory installed and wired accessories are

available.