Troubleshooting – unit – Greenheck Fan 455924 ERV-522 User Manual

Page 34

34

Energy Recovery Ventilator

Troubleshooting – Unit

Always have a completed Pre Start-Up Checklist, unit Start-Up Checklist, and Optional Accessories Checklist prior to requesting parts or

service information.

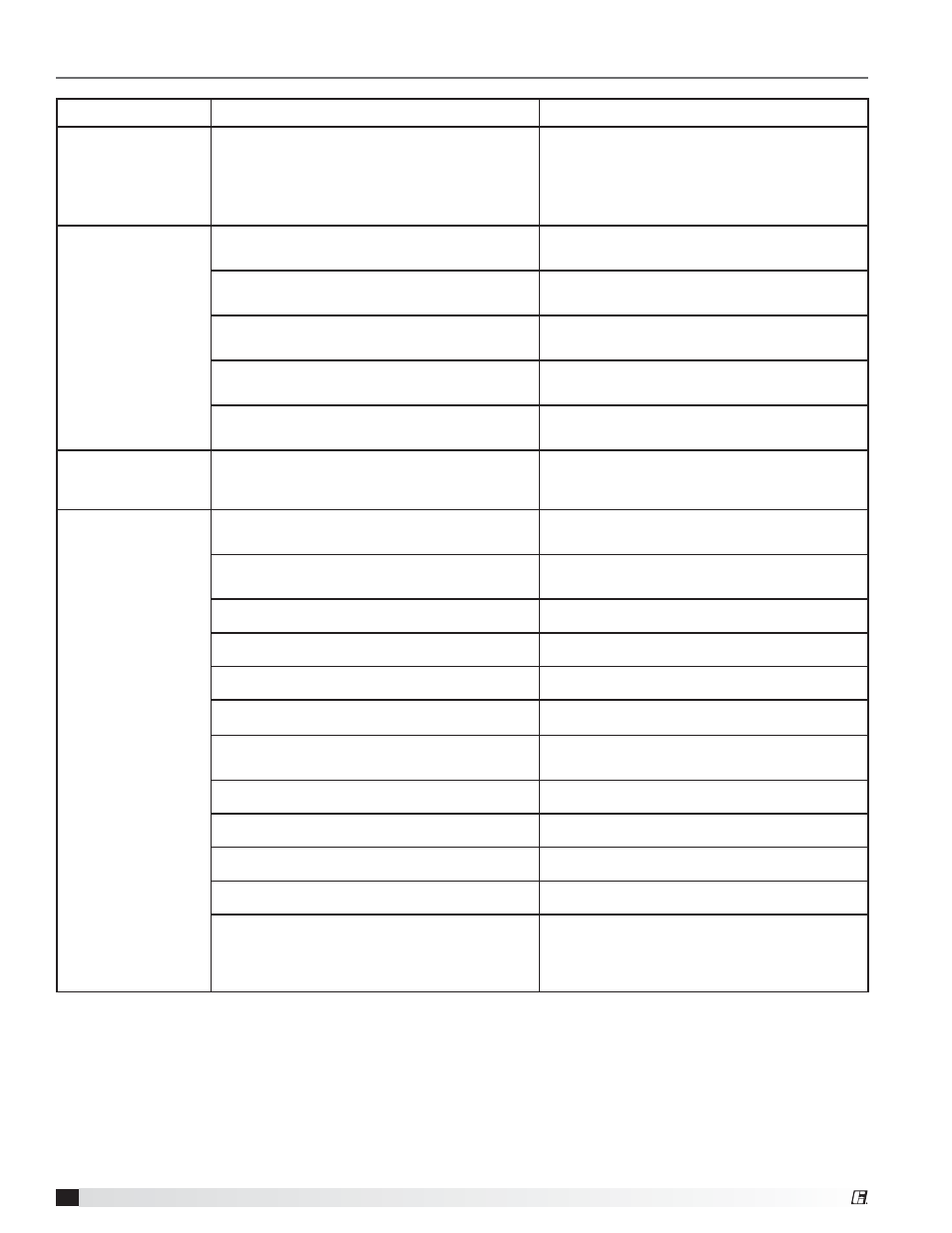

Symptom

Possible Cause

Corrective Action

One or both

blowers turn off

intermittently and

back on after

about 2 minutes

Exhaust Only frost control sensors are tripping.

Adjust frost temperature sensor set point as

needed.

Energy wheel does

NOT turn

Air seals are too tight.

See Energy Recovery Wheel under Unit Start-Up

section.

“Economizer” sensors are operating.

Adjust temperature or enthalpy set points as

needed.

No power to wheel motor.

Make sure wheel drive is plugged in. Verify

power is available.

Wheel drive belt.

Check for loose or broken belts. Replace belts

(consult factory).

VFD overload. (OL1 on readout)

Refer to VFD section. Compare motor amp

rating to setting in VFD. Adjust accordingly.

Energy wheel runs

intermittently

Wheel motor overloads are tripping, due to

rubbing between wheel and air seals.

Recheck air seals, make sure they are not too

tight. See Energy Recovery Wheel under Unit

Start-Up Section.

Excessive noise

or vibration

Fan wheel rubbing on inlet.

Adjust wheel and/or inlet cone. Tighten wheel

hub or bearing collars on shaft.

Bearings.

Replace defective bearing(s). Lubricate

bearings. Tighten collars and fasteners.

Wheel out of balance.

Replace or rebalance.

Loose wheel on shaft.

Tighten wheel setscrew.

Loose motor or blower sheave.

Tighten sheave setscrew.

Belts too loose.

Adjust belt tension after 24 hours of operation.

Belts too tight.

Loosen to maintain a 3/8 inch deflection per

foot of span between sheaves.

Worn belt.

Replace.

Motor base or blower loose.

Tighten mounting bolts.

Buildup of material on wheel.

Clean wheel and housing.

Bearing and drive misaligned.

Realign.

Noise being transmitted by duct.

Make sure ductwork is supported properly.

Make sure ductwork metal thickness is sized for

proper stiffness. Check duct size at discharge to

ensure that air velocities are not too high.