Spindle alignment, Horizontal position alignment – Grizzly Horizontal/Vertical Rotary Table G9298 User Manual

Page 11

-9-

g9298/g9299/g9300 rotary table

Spindle Alignment

Whether the rotary table is mounted horizontally

or vertically, you must align the centers of the

rotary table and mill spindle to achieve quality

results.

there are many ways to align the rotary table,

and it is up to the machinist and his capabilities to

decide which approach is best.

Horizontal position Alignment

two methods are described below for aligning

the spindles when the rotary table is mounted

horizontally.

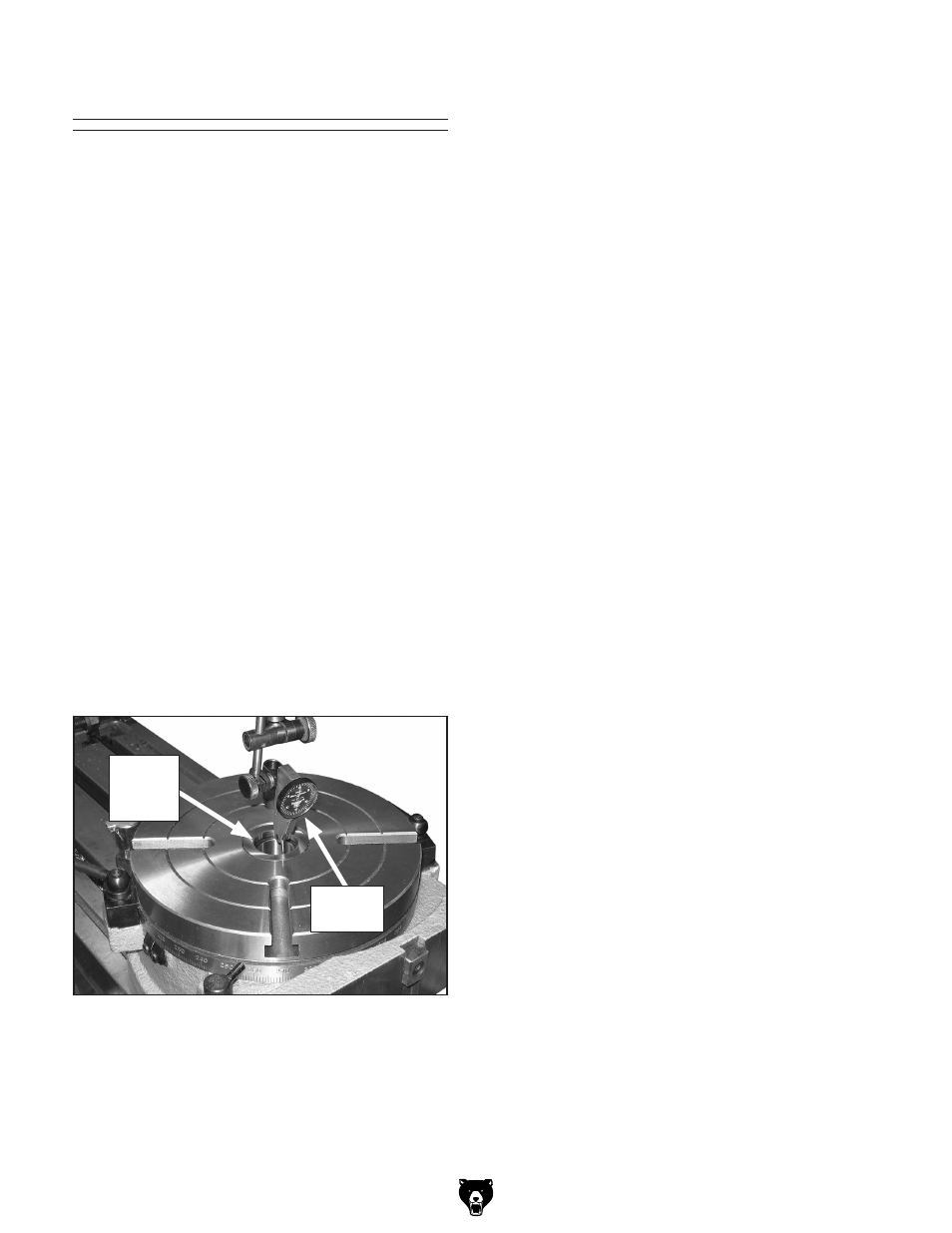

To use a test indicator to align the rotary

table:

1. disConneCt Mill FroM poWer!

2. Mount a test indicator on the mill spindle and

position the indicator tip on the inside vertical

surface of the rotary table spindle bore, as

shown in

figure 4.

Note: Refer to Accessories on Page 15 for

test indicator options from Grizzly.

figure 4. test indicator properly positioned.

test

indicator

spindle

Bore

step

3. turn the mill spindle so that the test indicator

is aligned to the X-axis of the mill table.

Note: For best results, turn the mill spindle in

only one direction.

4. slowly move the mill table until the test indi-

cator reads zero deviation.

5. rotate the mill spindle and test indicator 90°,

then repeat

Step 4.

6. repeat Step 5 until the test indicator reads

zero deviation in all four directions.

Tip: Use a mirror to read the indicator when

it is facing away from you.

To use an edge finder to align the rotary

table:

1. Mount an edge finder into the mill spindle,

then position it roughly in the center of the

rotary table spindle bore and below the rotary

table surface.

2. turn the spindle ON and set the speed to

800–1000 rpM, then slowly move the mill

table along the X-axis in one direction.

3. When you find the edge of the rotary table

spindle bore, note the position of the table on

the handwheel dial.

Note: When recording the mill table position,

take into account the backlash that is usually

present in the leadscrew.

4. slowly move the mill table in the opposite

direction until you again find the edge of the

spindle bore, then note the table's position on

the handwheel dial.

5. Calculate the difference of the mill table posi-

tions noted in

Steps 3–4, then subtract

1

⁄

2

the

diameter of the edge finder.