Adjusting blade guides – Grizzly G0659 User Manual

Page 29

g0659 9" x 14" Vertical Metal-Cutting Bandsaw

-27-

Tools Needed:

Qty

hex Wrench 4mm .............................................. 1

slotted screwdriver ........................................... 1

the blade guides provide side-to-side support

to help keep the blade straight while cutting.

properly adjusted blade guides are essential to

making accurate cuts.

the ideal blade guide position on the Model

g0659 accomplishes the following:

•

the blade guides exert enough force on the

blade to hold it parallel to the path of the cut.

•

the blade is held square to the table.

•

the blade is supported during operation by

the flanges on the blade guides, but does not

ride directly upon them.

•

the blade is not forced to bend excessively

as it passes through the blade guides.

Upper and Lower Guide Bearing

Adjustment

1. Make sure the blade tracks properly and is

correctly tensioned.

2. disConneCt BAndsAW FroM poWer!

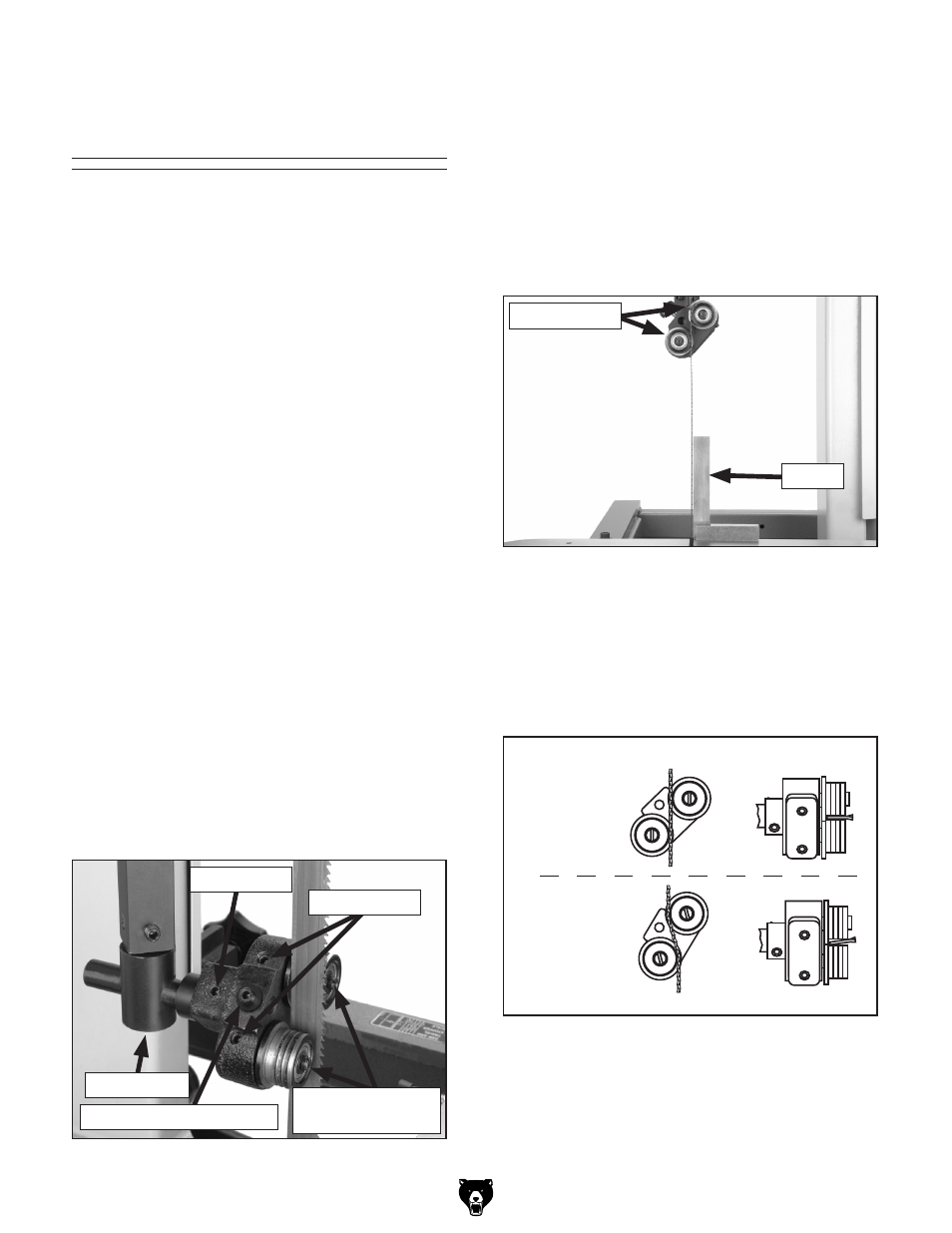

3. Familiarize yourself with the blade guide con-

trols shown in

figure 34.

Adjusting Blade

Guides

figure 34. upper blade guide controls.

set screw A

set screw B

set screws C

guide Bearing

eccentric spindles

Blade guard Cap screw

Note: In most cases, the only adjustment

necessary is to adjust the guide bearing

eccentric spindles. This adjustment is out-

lined in

Steps 4–6 below. If the proper posi-

tioning cannot be accomplished by turning

the eccentric spindles, you must re-position

the lower and upper blade guide assemblies,

as outlined later in this section.

4. loosen set screws C (figure 35).

5. Adjust the blade guides by turning the slotted

eccentric spindles as necessary so the blade

is held flat between the blade guide wheels

but not so tight that the blade must bend

between them (

figure 36). Make sure the

blade remains square to the table.

6. tighten the set screws.

7. repeat Steps 4–6 for the lower blade guide

assembly.

figure 35. Blade squared.

set screws C

square

IDEK>:L

;GDCIK>:L

IDDADDH:

IDDI><=I

8DGG:8I

>C8DGG:8I

figure 36. Blade guide wheel position.