4 mounting drives, 1 check before mounting, 2 mounting procedures – FUJITSU MAW3073NC/NP User Manual

Page 83

C141-E226

5-11

5.4 Mounting

Drives

5.4.1

Check before mounting

Reconfirm if the CN2 setting terminal is set correctly according to Table 5.8 before mounting the

NP model drives in the system cabinet. For the CN2 setting terminal location, see Section 5.3.

The NC model drives do not require the following check.

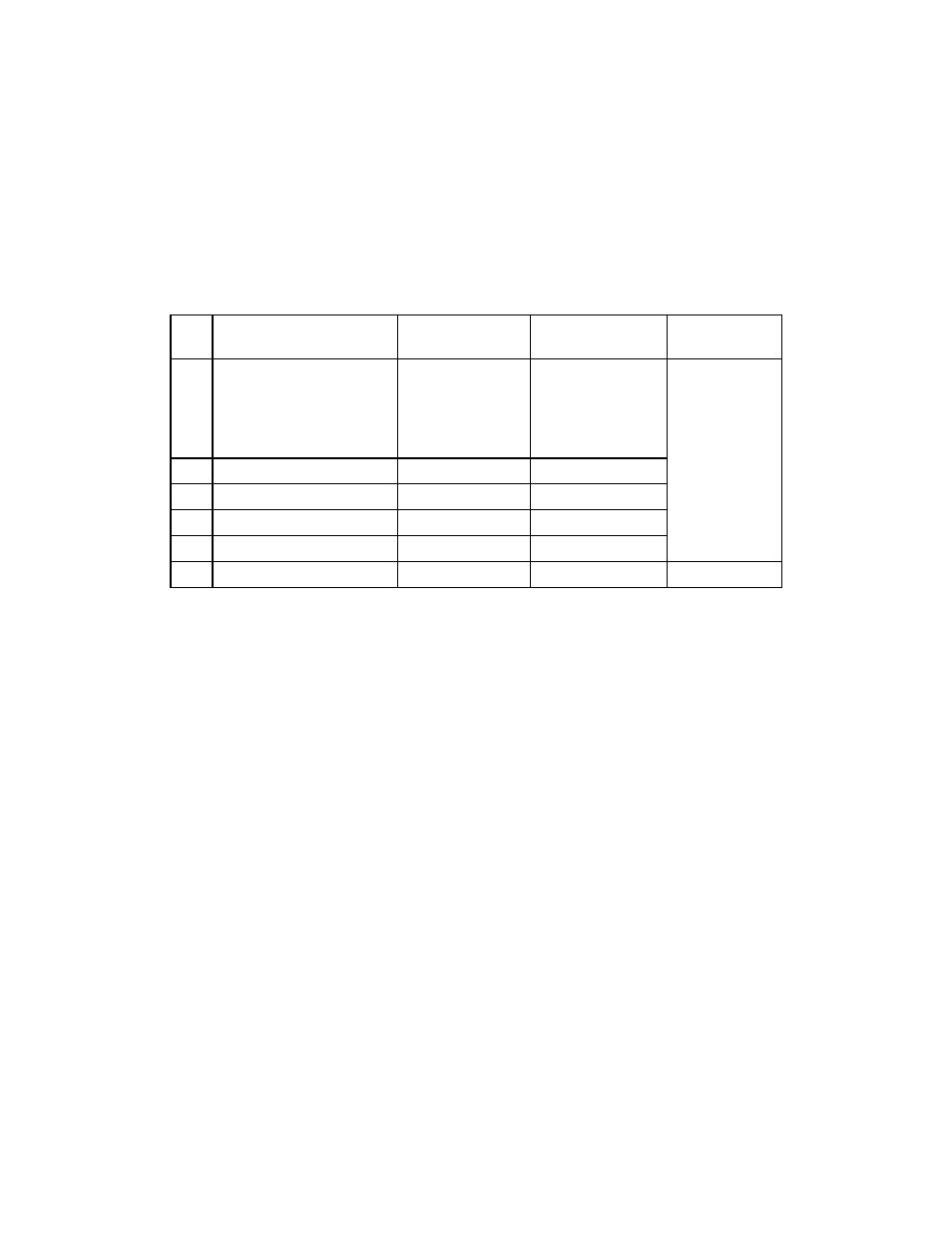

Table 5.8

Setting check list (NP model only)

No.

Setting contents

(Check item)

Pin pair on CN2

Check Remarks

1 SCSI

ID

1/2

3/4

5/6

7/8

(SCSI ID = __)

Upper bus

(DB 8 to 15 PI)

not connected

2 Write

protect

9/10

Short Open

3

Motor start mode

11/12

Short Open

4 Force

Narrow

13/14

Short Open

5

Force single ended

15/16

Short Open

6

Terminator power supply

23/24

Short Open

5.4.2 Mounting

procedures

Since mounting the drive depends on the system cabinet structure, determine the work procedures

considering the requirements specific to each system. The general mounting method and items to

be checked are shown below.

See Subsection 4.1 for the details of requirements for installing the HDD.

1) With a system to which an external operator panel is mounted, if it is difficult to access the

connector after the drive is mounted on the system cabinet, connect the external operator panel

cable before mounting the drive.

2) Fix the drive in the system cabinet with four mounting screws as follows:

•

The drive has 10 mounting holes (both sides: 3

× 2, bottom: 4). Fix the drive by using

four mounting holes of both sides of the drive or the bottom. (See Figure 4.5)

•

Use mounting screws of which lengths inside the drive mounting frame are 5.0 mm or less

when the screws are tightened (see Figure 4.4).

•

When mounting the drive, be careful not to damage parts on the PCA.

3) Confirm the DE is not touching the frame on the system side excluding the screw installing

part after tightening the screws. At least 2.5mm of clearance is required between the DE and

the frame. (Indicated in Figure 4.4)

4) When using an electric screwdriver, use an electric screwdriver that does not apply a force on

the drive that would exceed the drive’s specifications.