E. junction box installation, D. electrical service and repair – Heat & Glo Fireplace SLR (COSMO) User Manual

Page 46

Heat & Glo • SLR • 2143-900 Rev. B • 7/08

46

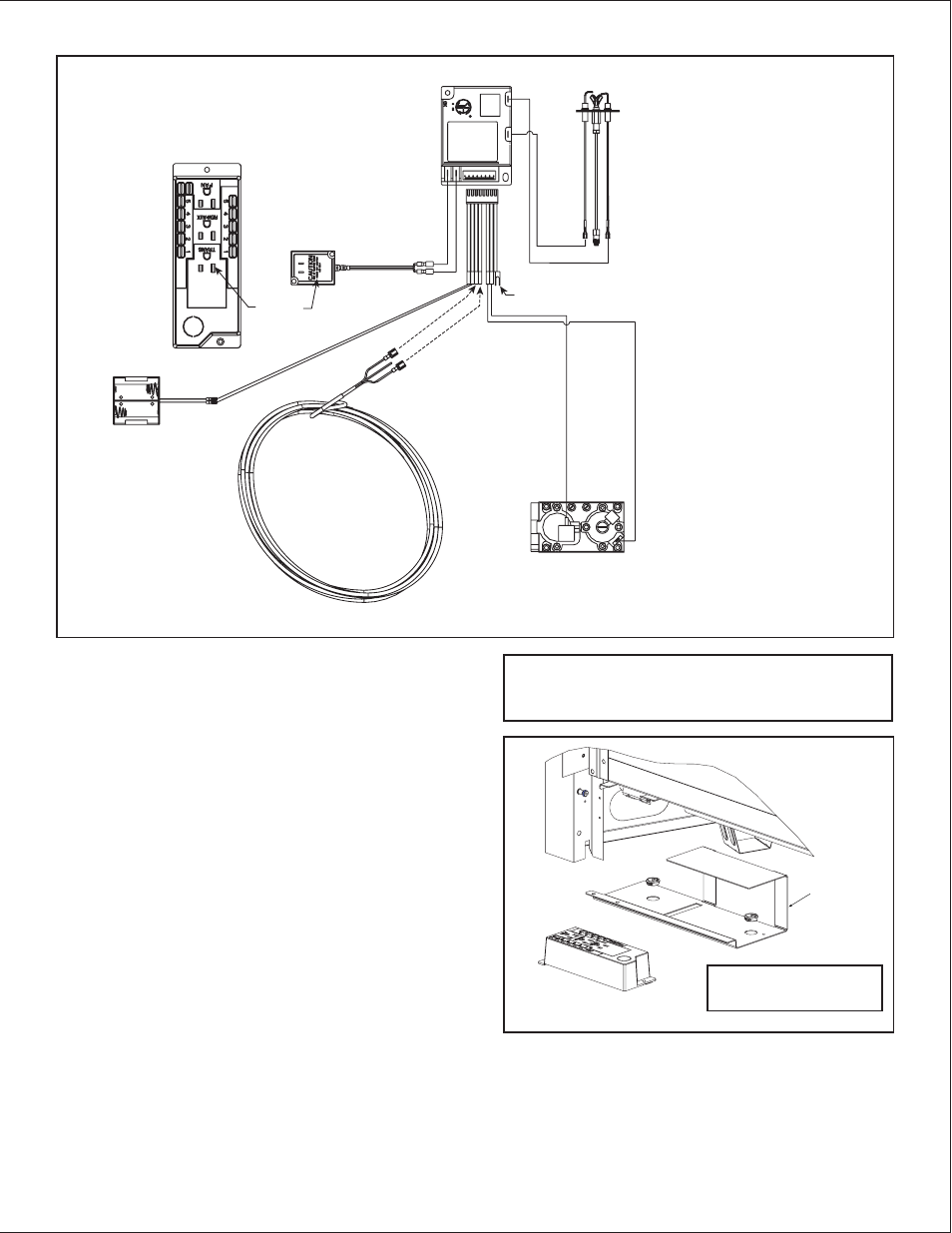

Figure 12.2 Intellifi re Pilot Ignition (IPI) Wiring Diagram with Wall Switch or Thermostat

Figure 12.3 Junction Box Detail

NOTICE: DO NOT wire

110 VAC to wall switch.

E. Junction Box Installation

1. Remove the two screws that hold the junction box

bracket to the right corner of the fi replace.

2. Remove the one screw that secures the junction box

to the junction box bracket.

3. Route the wire through the strain relief in the outer

wrap and down through the strain relief on left side of

the junction box bracket and up through the right strain

relief. See Figure 12.3.

4. Make the connection inside the junction box to the 120V

wire. Connect green to the ground nut, black to black

and white to white.

5. Reattach junction box to junction box bracket with one

screw.

6. Reattach the junction box bracket to the appliance with

two screws.

TRANSFORMER

3 VAC

PLUG IN

BLACK

RED

BATTERY PACK

THERMOSTAT

WIRE ASSEMBLY

WIRES

(TO BROWN)

ORANGE

GREEN

VALVE

WHITE

ORANGE

IGNITION MODULE 3 VAC

INTERMITTENT PILOT IGNITOR

HOT

NEUTRAL

I

S

GROUND TO

FIREPLACE

CHASSIS

NOTE: 1. Ignition module, valve, pilot, and

wall switch operate on 3 volts. 120 VAC is

required at junction box unless equipped

with battery back-up.

JUNCTION BOX

BRACKET

D. Electrical Service and Repair

WARNING! Risk of Shock! Label all wires prior to dis-

connection when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify proper

operation after servicing.

WARNING! Risk of Shock! Replace damaged wire with

type 105° C rated wire. Wire must have high temperature

insulation.

NOTE: There is an alternative access to the junction box.

This can be accessed by removing the valve assembly.

See Figure 11.2.

In the event that the junction box needs to be accessed

or installed after fi nish methods have been applied, ac-

cess is possible by removing the valve assembly. See

Fig. 11.2. Bend the top heat shield back and remove the

one screw that secures the junction box to the bracket.

Ensure the heat shield is bent back so that it is positioned

above the junction box.

О

О