Maintenance – Glow-worm Ultracom2 cxi User Manual

Page 43

0020112601_02 - 10/12 - Glow-worm

- 41 -

MAINTENANCE

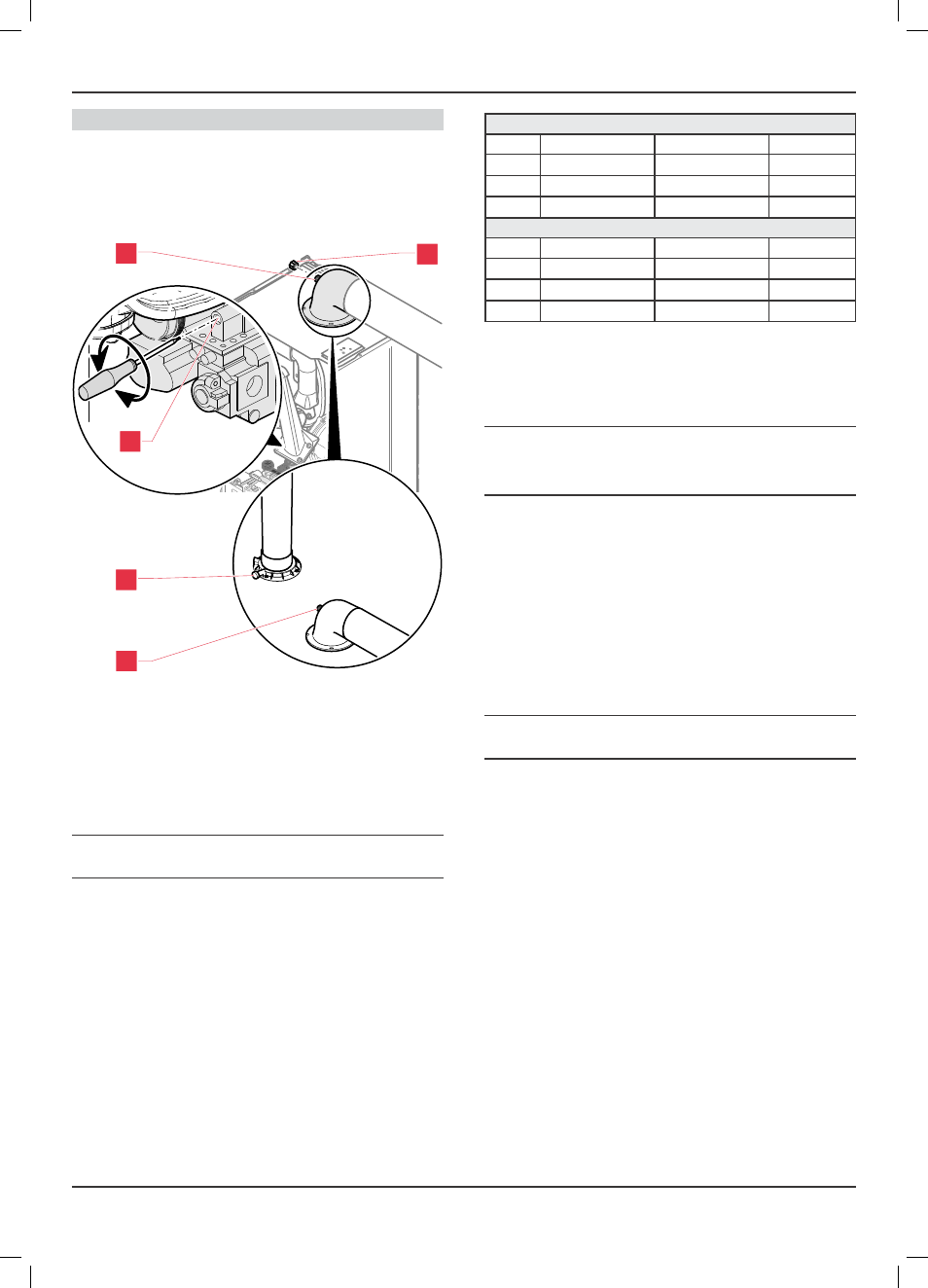

Combustion check and setting the air/gas ratio

• Remove the front casing panel, see diagram above and

hinge down the control box. Taking care not to touch any

internal components, proceed as follows:

• Connect the CO2 combustion analyser to the relevant test

point, see diagram opposite.

24

2

3

1

2B

2A

Key

1 Throttle

2 Combustion analyser sample point

2A flue elbow

2b Vertical flue adaptor

3 Cap

18.3.3

Maximum rate check and adjustment

i

To verify the maximum gas rate CO2 setting the

appliance must be checked at the maximum rate.

• Activate the test mode "P.01" and set the value to 100 in

order to force the burner at P. max. See chapter "Specific

adjustment ► Appliance technical settings and parameter list

► Test modes".

• Wait approximately 5 minutes to read a stabilised CO2 value.

• Check that the value is within the range specified in table in

the “check” column.

G20 burner % CO2

Model

Check (case on)

Setting (case off)

CO/CO2 ratio

24cxi

9.2 ± 0.3%

9 ± 0.2%

0.004

30cxi

9.2 ± 0.3%

9 ± 0.2%

0.004

35cxi

9.2 ± 0.3%

9 ± 0.2%

0.004

G31 burner % CO2

Model

Check (case on)

Setting (case off)

CO/CO2 ratio

24cxi

10.3 ± 0.3%

10.1 ± 0.2%

0.004

30cxi

10.3 ± 0.3%

10.1 ± 0.2%

0.004

35cxi

10.3 ± 0.3%

10.1 ± 0.2%

0.004

If the combustion reading is not within the acceptable values

and the integrity of the complete flue system and combustion

circuit seals have been verified and the inlet gas pressure (and

gas rate) have been verified, then, it will necessary to adjust the

combustion rate of the appliance.

i

Adjustment is made by turning the throttle an ⅛

of a turn, waiting 1 minute to allow the appliance

to stabilise before checking or making further

adjustments.

• Remove the sticker covering the “throttle” adjustment screw,

if fitted.

• Rotate the “throttle” (1) (anti-clockwise to increase), to the

required CO2, refer to previous diagram and the “Setting”

column in the table.

• When you have finished, press the On/Off button to exit the

test modes.

• Remove the analyser probe and replace the cap on the

sampling point, replace the controls fascia, and the front

casing panel.

i

Remember to replace the sample point cap on

completion of the test.

18.3.4

Gas rate check

• Check the gas rates as described in the commissioning

section.

18.3.5

Completion

If it is not possible to achieve the required results for either the

combustion or gas rates, it will be necessary to complete a full

service of the appliance and then repeat the combustion check

procedure.

If after servicing and adjustment of the appliance the

combustion values are still unacceptable and after further

remedial work has been carried out, the appliance must be

disconnected until the CO/CO2 ratio is acceptable.

• Advice can be sought from the Glow-worm Technical

Helpline.