Maintenance – Glow-worm Ultracom2 cxi User Manual

Page 42

0020112601_02 - 10/12 - Glow-worm

- 40 -

MAINTENANCE

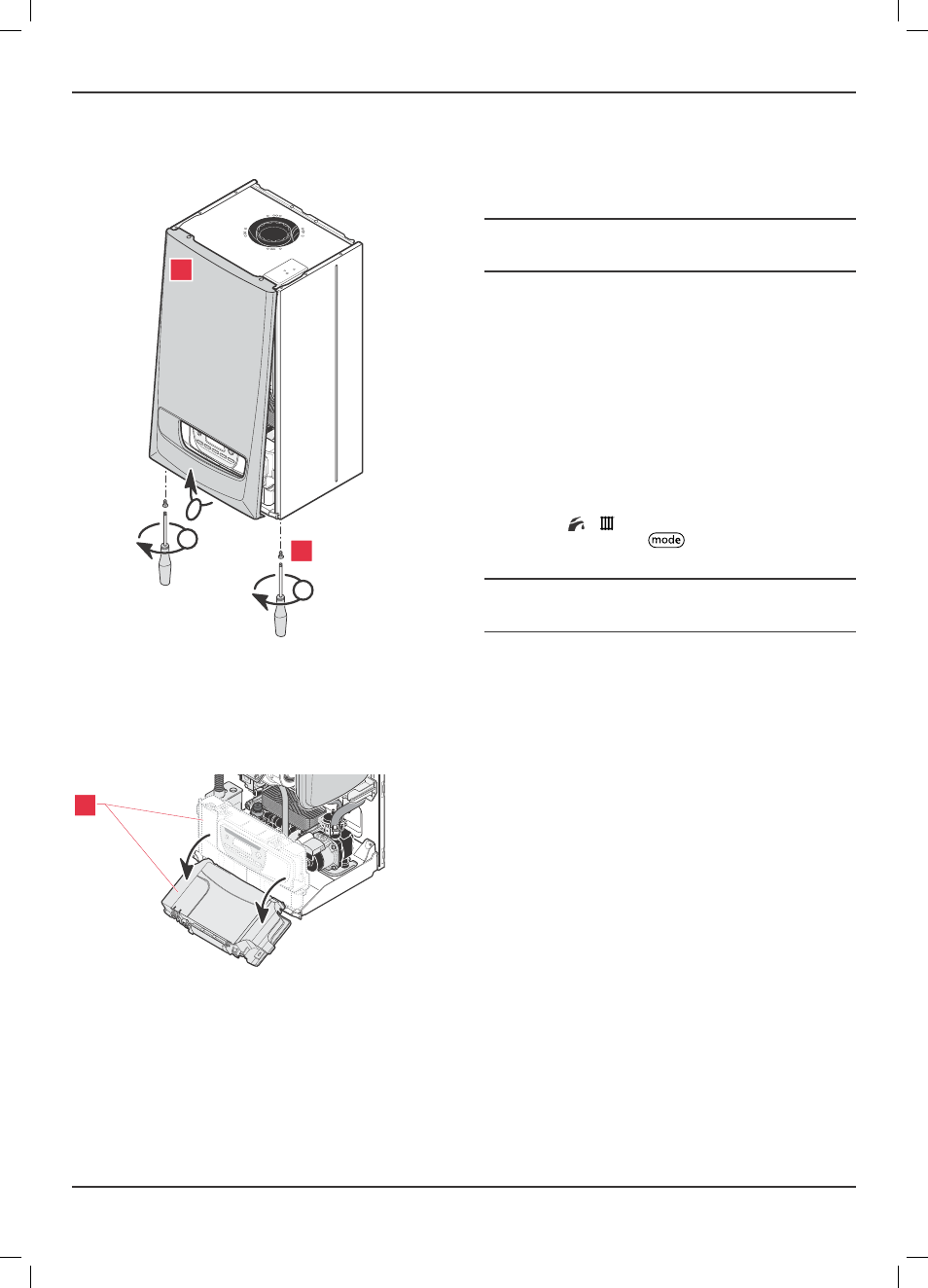

18.2 Casing removing

18.2.1

front panel

24

V

230

V

A

A

B

1

2

Key

1 front panel

2 front panel retaining screw

• Undo the two screws (2) on the underside of the front panel

and remove the front panel (1).

18.2.2

Control box

24

V

230

V

1

Key

1 Control box

• Position the control box (1) into the service position.

18.3 Combustion check and setting the air/gas

ratio valve

18.3.1

Competency to carry out the check of

combustion performance

i

BS 6798: 2009 Specification for installation and

maintenance of gas-fired boilers of rated input not

exceeding 70kW net advises that:

- The person carrying out a combustion measurement must be

assessed as competent in the use of a flue gas analyser and

the interpretation of the results.

- The flue gas analyser used should be one meeting

the requirements of BS7927 or BS-EN50379-3 and be

calibrated in accordance with the analyser manufacturers’

requirements.

- Competence can be demonstrated by satisfactory completion

of the CPA1 ACS assessment, which covers the use of

electronic portable combustion gas analysers in accordance

with BS 7967, parts 1 to 4.

• Ensure that the gas analyser is set to the correct fuel setting.

• Select the “ + ”, constant central heating with DHW

function by pressing the “

” button repeatedly, refer to

commissioning section. The boiler should fire automatically.

i

Safe combustion can only be verified by measuring

CO/CO2 ratio. This must not exceed the value

shown in the table opposite.

18.3.2

Preliminaries

Prior to, during servicing and after any maintenance or changed

parts, the following inspection must be carried out.

• The integrity of the flue system and flue seals.

• The integrity of the appliance combustion circuit and relevant

seals.

• A visual inspection of the flame quality.

• Electrical, gas and water connections.

• System pressure.

• The combustion performance, refer to the following

procedure.

• The operational gas inlet pressure and gas rates, refer to

the commissioning section paragraph 12.5. Correct any fault

before continuing.