Dunkirk DWB Series User Manual

Page 19

19

6 - COMBUSTION AIR AND VENTILATION

Provide combustion air and ventilation air in accordance

with the section “Air for Combustion and Ventilation,”

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

or Sections 8.2, 8.3 or 8.4 of Natural Gas and Propane

Installation Code, CAN/CSA B149.1, or applicable

provisions of local building codes.

Provide make-up air where exhaust fans, clothes dryers,

and kitchen ventilation equipment interfere with proper

operation.

National Fuel Gas Code recognizes several methods

of obtaining adequate ventilation and combustion air.

Requirements of the authority having jurisdiction may

override these methods.

• Engineered Installations. Must be approved by

authority having jurisdictions.

• Mechanical Air Supply. Provide minimum of 0.35

cfm per Mbh for all appliances located within space.

Additional requirements where exhaust fans installed.

Interlock each appliance to mechanical air supply

system to prevent main burner operation when

mechanical air supply system not operating.

• All Indoor Air. Calculate minimum volume for all

appliances in space. Use a different method if

minimum volume not available.

◊ Standard Method. Cannot be used if known air

infi ltration rate is less than 0.40 air changes per

hour. See Table 5 for space with boiler only. Use

equation for multiple appliances.

Volume ≥ 50 ft3 x Total Input [Mbh]

◊ Known Air Infi ltration Rate. See Table 3 for

space with boiler only. Use equation for multiple

appliances. Do not use an air infi ltration rate (ACH)

greater than 0.60.

Volume ≥ 15 ft3/ACH x Total Input [Mbh]

◊ Refer to National Fuel Gas Code for opening

requirements between connection indoor spaces.

• All Outdoor Air. Provide permanent opening(s)

communicating directly or by ducts with outdoors.

◊ Two Permanent Opening Method. Provide opening

commencing within 12 inches of top and second

opening commencing within 12 inches of bottom

enclosure.

Direct communication with outdoors or

communicating through vertical ducts. Provide

minimum free area of 1 in2 per 4 Mbh of total input

rating of all appliances in enclosure.

Communicating through horizontal ducts. Provide

minimum free area of 1 in2 per 2 Mbh of total input

rating of all appliances in enclosure.

◊ One Permanent Opening Method. Provide opening

commencing within 12 inches of top of enclosure.

Provide minimum clearance of 1 inch on sides

and back and 6 inches on front of boiler (does not

supersede clearance to combustible materials).

◊ Combination Indoor and Outdoor Air. Refer to

National Fuel Gas Code for additional requirements

for louvers, grilles, screens and air ducts.

• Combination Indoor and Outdoor Air. Refer toNational

Fuel Gas Code for application information. National Gas

and Propane Installation Code Requires providing air

supply in accordance with:

• Section 8.2 and 8.3 when combination of appliances

has a total input of up to and including 400 Mbh

(120kW).

Does not have draft control device.

• Section 8.4 when combination of appliances has total

input exceeding 400 Mbh (120 kW).

• Refer to Natural Gas and Propane Installation Code

for specifi c air supply requirements for enclosure or

structure where boiler is installed, including air supply

openings and ducts.

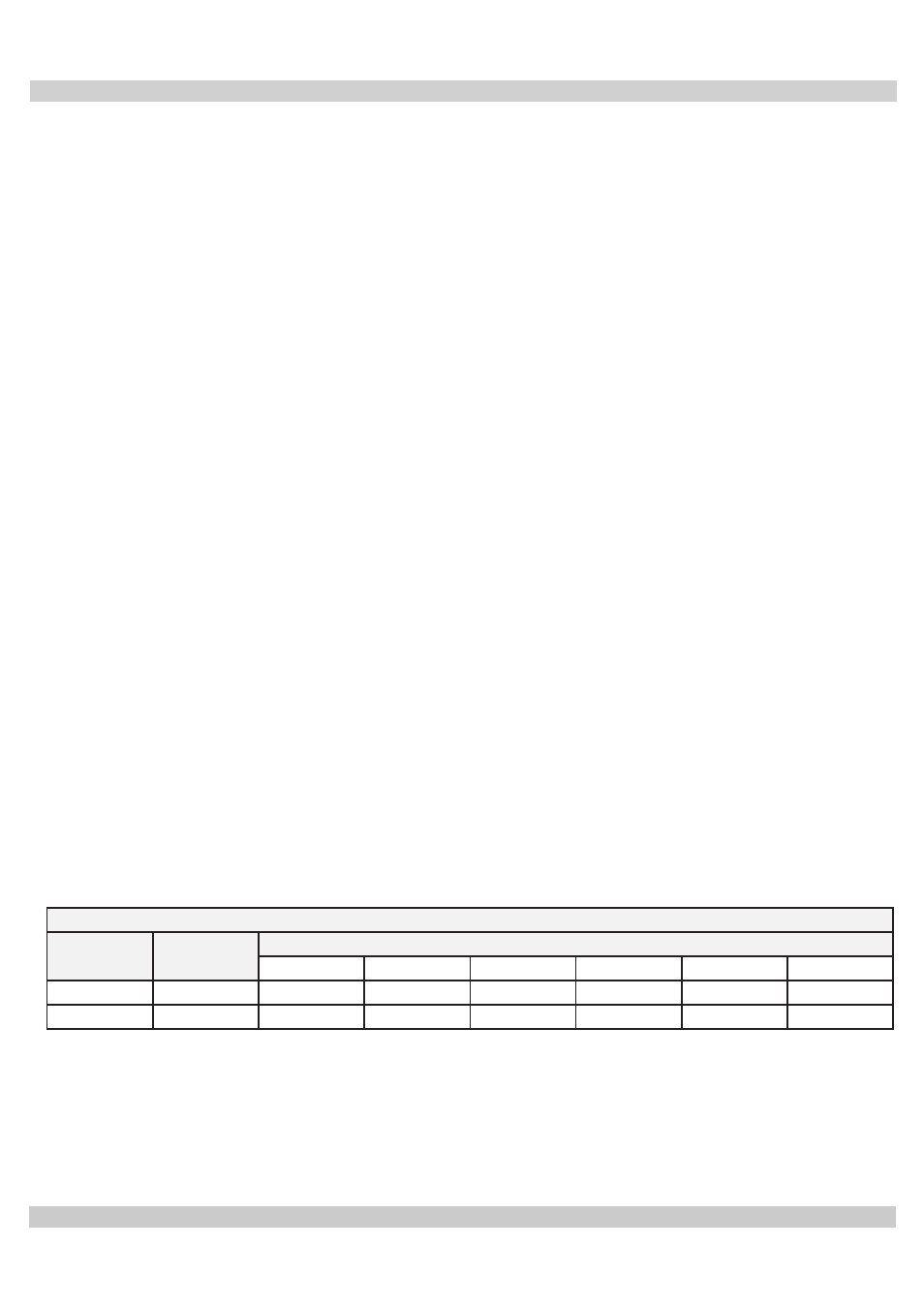

Table 5 - Air Infi ltration

Input Mbh

Standard

Method

Known Air Infi ltration Rate Method (Air Changes Per Hour)

0.1

0.2

0.3

0.4

.05

0.6

100

5000

15,000

7,500

5,000

3,750

3,000

2,500

130

6500

19,500

9,750

6,500

4,875

3,900

3,250