Tightening flare type tube fittings, Tightening o-ring fittings – Wheatheart R Series Augers User Manual

Page 43

W

HEATHEART

- R S

ERIES

A

UGERS

9. A

PPENDIX

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

9.3. T

IGHTENING

F

LARE

T

YPE

T

UBE

F

ITTINGS

30758 R1

43

9.3. TIGHTENING FLARE TYPE TUBE FITTINGS

1. Check flare and flare seat for defects that might cause leakage.

2. Align tube with fitting before tightening.

3. Lubricate connection and hand tighten swivel until snug.

4. To prevent twisting the tube(s), use two wrenches. Place one wrench on the

connector body and with the second tighten the swivel nut to the torque

shown.

9.4. TIGHTENING O-RING FITTINGS

1. Inspect o-ring and seat for dirt or obvious defects.

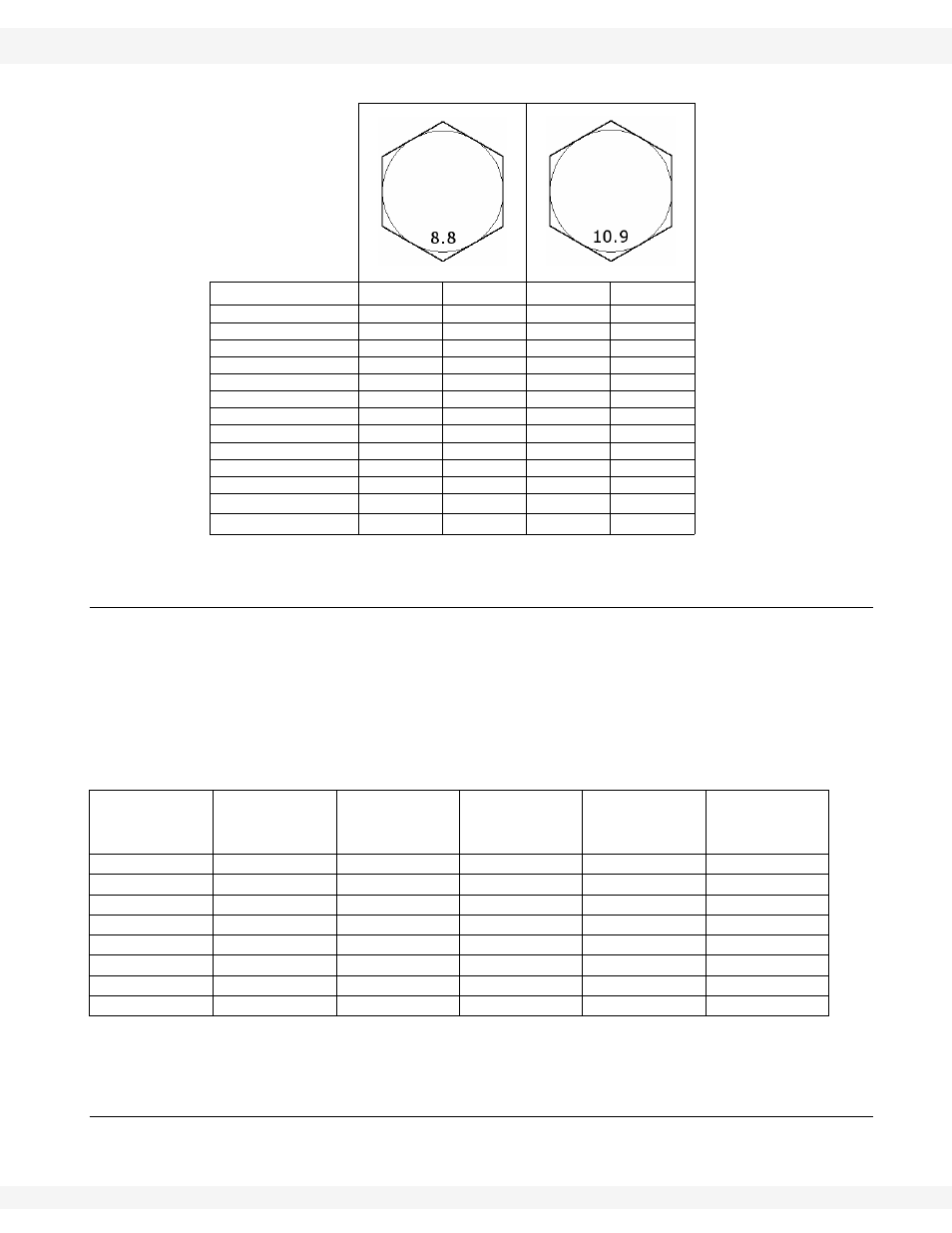

Table 9.3 Metric Bolt Torque

BOLT DIAMETER

(Nm)

(lb-ft)

(Nm)

(lb-ft)

M3

0.5

0.4

1.8

1.3

M4

3

2.2

4.5

3.3

M5

6

4

9

7

M6

10

7

15

11

M8

25

18

35

26

M10

50

37

70

52

M12

90

66

125

92

M14

140

103

200

148

M16

225

166

310

229

M20

435

321

610

450

M24

750

553

1050

774

M30

1495

1103

2100

1550

M36

2600

1917

3675

2710

Table 9.4 Flare Type Tube Fittings

Tube Size OD

(in.)

Nut Size

Across Flats

(in.)

Torque

Values(N-m)

a

Torque Values

(lb-ft)

a

# of Turns to

Tighten (Flats)

(After Finger

Tightening)

(Turn)

3/16

7/16

8

6

1

1/6

1/4

9/16

12

9

1

1/6

5/16

5/8

16

12

1

1/6

3/8

11/16

24

18

1

1/6

1/2

7/8

46

34

1

1/6

5/8

1

62

46

1

1/6

3/4

1 1/4

102

75

3/4

1

7/8

1 3/8

122

90

3/4

1

a. * The torque values shown are based on lubricated connections as in reassemble.