Maintenance intervals, Maintenance procedures, Visual inspection – Wheatheart R Series Augers User Manual

Page 30

6. M

AINTENANCE

W

HEATHEART

- R S

ERIES

A

UGERS

6.2. M

AINTENANCE

I

NTERVALS

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

30

30758 R1

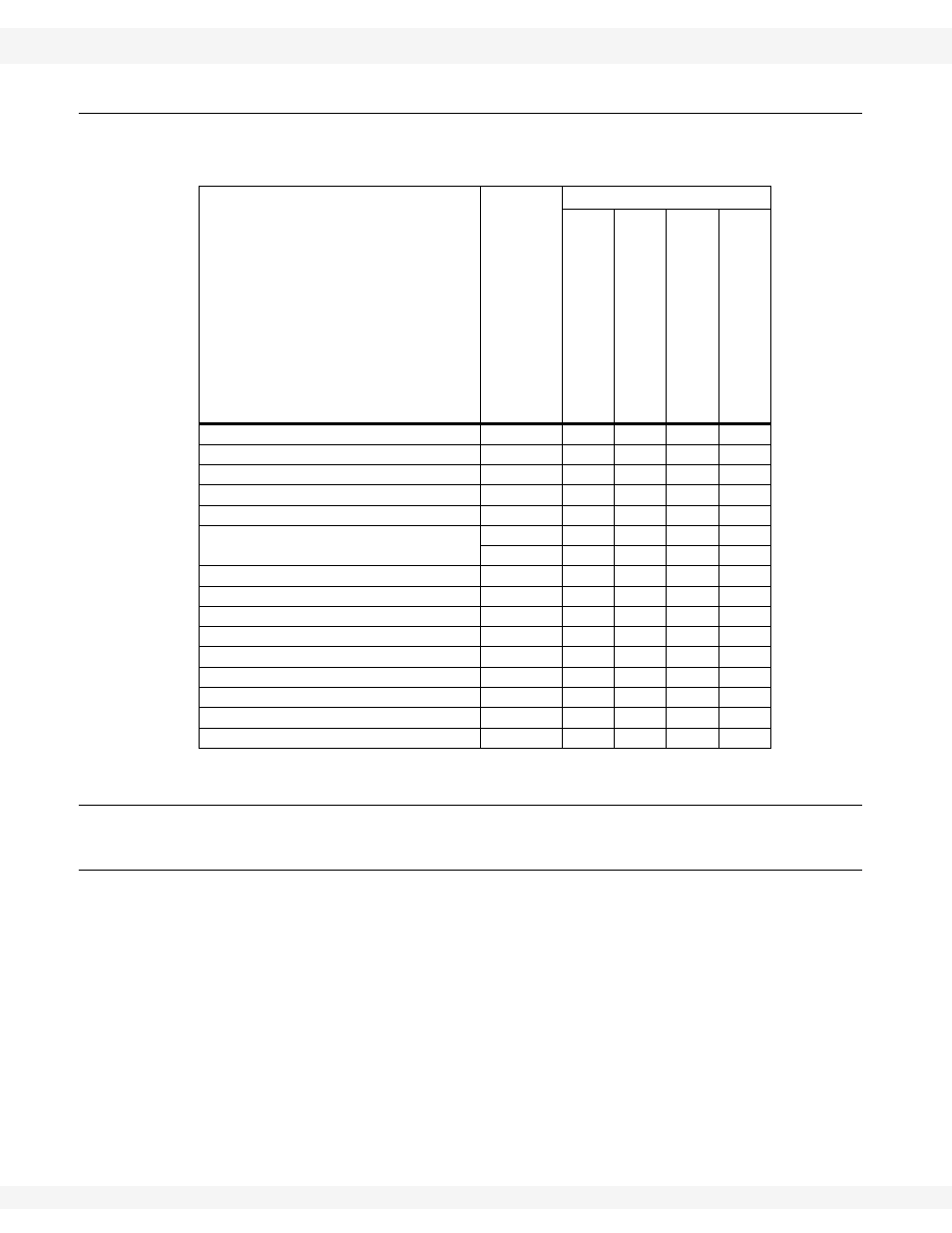

6.2. MAINTENANCE INTERVALS

Refer to Section 6.3. for details of service.

6.3. MAINTENANCE PROCEDURES

6.3.1. V

ISUAL

I

NSPECTION

Before beginning the visual inspection, chock auger wheels and ensure that all

operators are aware of safety precautions.

When inspecting look for possible defects, and the following:

• Ensure all guards are in place, and in good working order.

• Examine the auger for damage or unusual wear.

• Inspect the machine for evidence of oil leaks.

• Examine hydraulic hoses and fittings for leaks and cracks.

• Be sure all safety decals are in place and are legible.

• Check that drive belts are not frayed or damaged. Ensure they are prop-

erly adjusted and aligned.

Table 6.1 Maintenance Intervals

Time Period

Mai

ntenanc

e Pro

cedure

Daily (8000)BU

Pe

rio

dically

(40,00

0)BU

Annually (Be

fore

S

torage)

Annually

(Af

ter S

torage)

Visually Inspect the Unit

X

Check engine oil level

X

Service PTO Driveline

X

Check Air Filter

X

Service Upper Chain Drive

X

Service Belts

X

Grease Machine

X

Check Gear Box Oil Level

X

Check Winch

X

Clean Machine

X

Service Engine

X

Repack Wheel Bearings

X

Tighten Wheel Bolts

X

Change Gear Box Oil

X

Service Truss Cables (R 851 only) 6.3.10.

X