Cleaning machine, Repacking wheel bearings, Tightening wheel bolts – Wheatheart R Series Augers User Manual

Page 32

6. M

AINTENANCE

W

HEATHEART

- R S

ERIES

A

UGERS

6.3. M

AINTENANCE

P

ROCEDURES

R8-36, R8-41, R8-46, R8-51, R10-36, R10-41, & R10-51

32

30758 R1

1. Lockout all power.

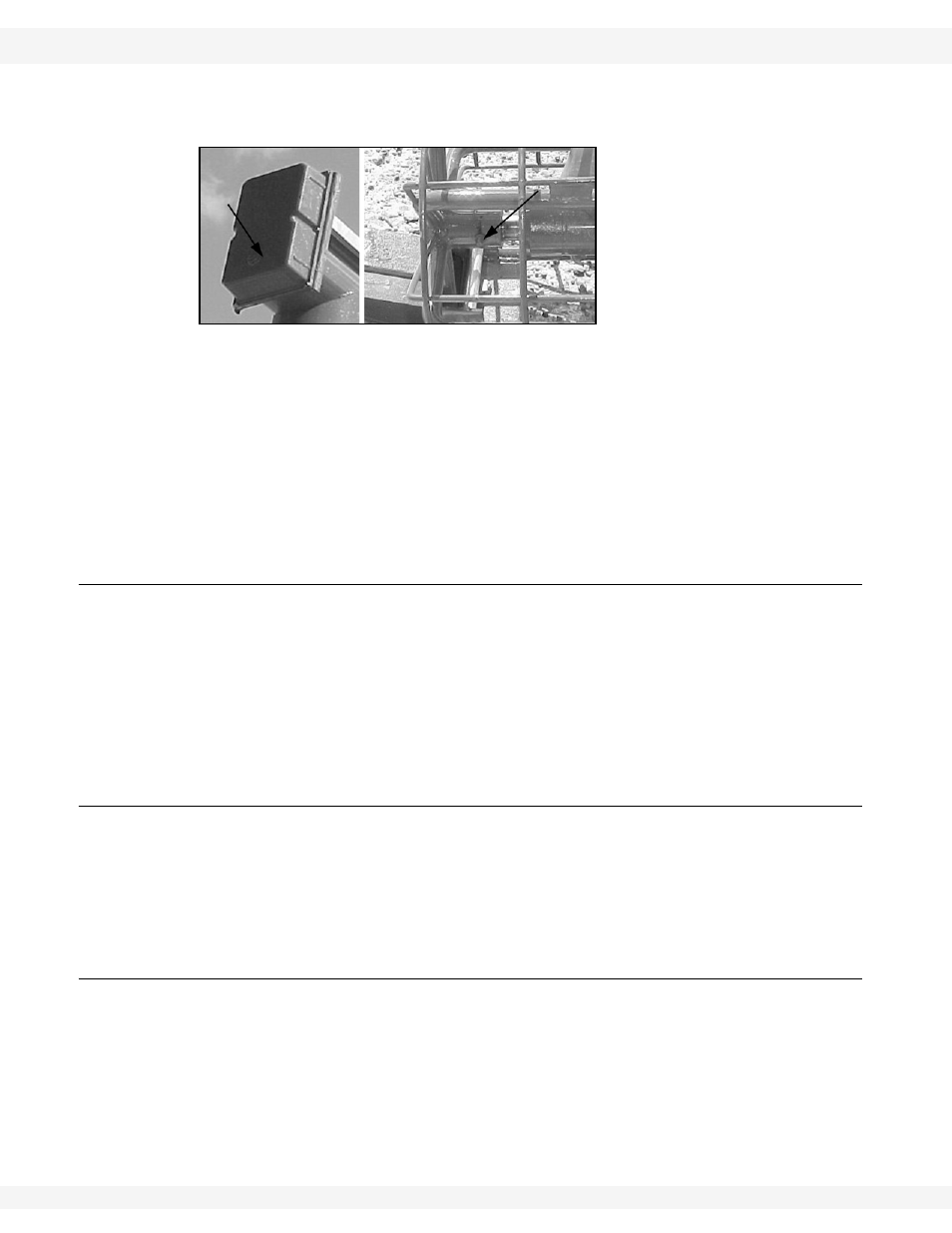

2. Grease points on the machine are shown in Figure 6.3.

Figure 6.3 Upper Chain Drive Zerk & Intake Zerk

3. Use grease recommended in Section 6.1.

4. Use only a hand-held grease gun.

5. Wipe grease fitting with a clean cloth before greasing to avoid injecting dirt

and grit.

6. If a fitting will not take grease, remove and clean thoroughly. Also clean

lubricant passageway. Replace fitting if necessary.

7. Replace and repair broken fittings immediately.

6.3.4. C

LEANING

M

ACHINE

1. Lockout all power.

2. Clean out excess grain from auger tube and intake.

3. Make sure nothing is obstructing the auger intake so water can run out.

4. Wash the tube with a water hose or pressure washer until all dirt, mud, debris,

or residue is washed from the auger.

5. Provide sufficient time for the water to drain from the auger.

6.3.5. R

EPACKING

W

HEEL

B

EARINGS

1. Block wheels and ensure unit is stable.

2. Remove the wheel bolts and the wheels.

3. Remove the wheel bearing and pack with grease. Refer to Section 6.1. for

recommended grease.

6.3.6. T

IGHTENING

W

HEEL

B

OLTS

1. Clean wheel and hub mounting surfaces to ensure there is no rust or debris.

2. Install the wheel and “finger tighten” the wheel bolts. Inspect to make sure the

wheel is sitting flush with the hub.

3. Tighten the wheel bolts with a torque wrench to 80 ft-lb (±10 ft-lb) of torque.

Note:

Tighten the wheel bolts in a diagonal pattern as in Figure 6.4.