6 troubleshooting, Pump loses prime or will not prime, Figure 6-1: troubleshooting chart – Hale ESP Priming System User Manual

Page 47: Troubleshooting, Figure 6-1, Troubleshooting chart, 6troubleshooting

47

ESP Primer System Instruction Guide

p/n: 029-0810-01-0

T r ou b les h oo tin g

❑

6

Troubleshooting

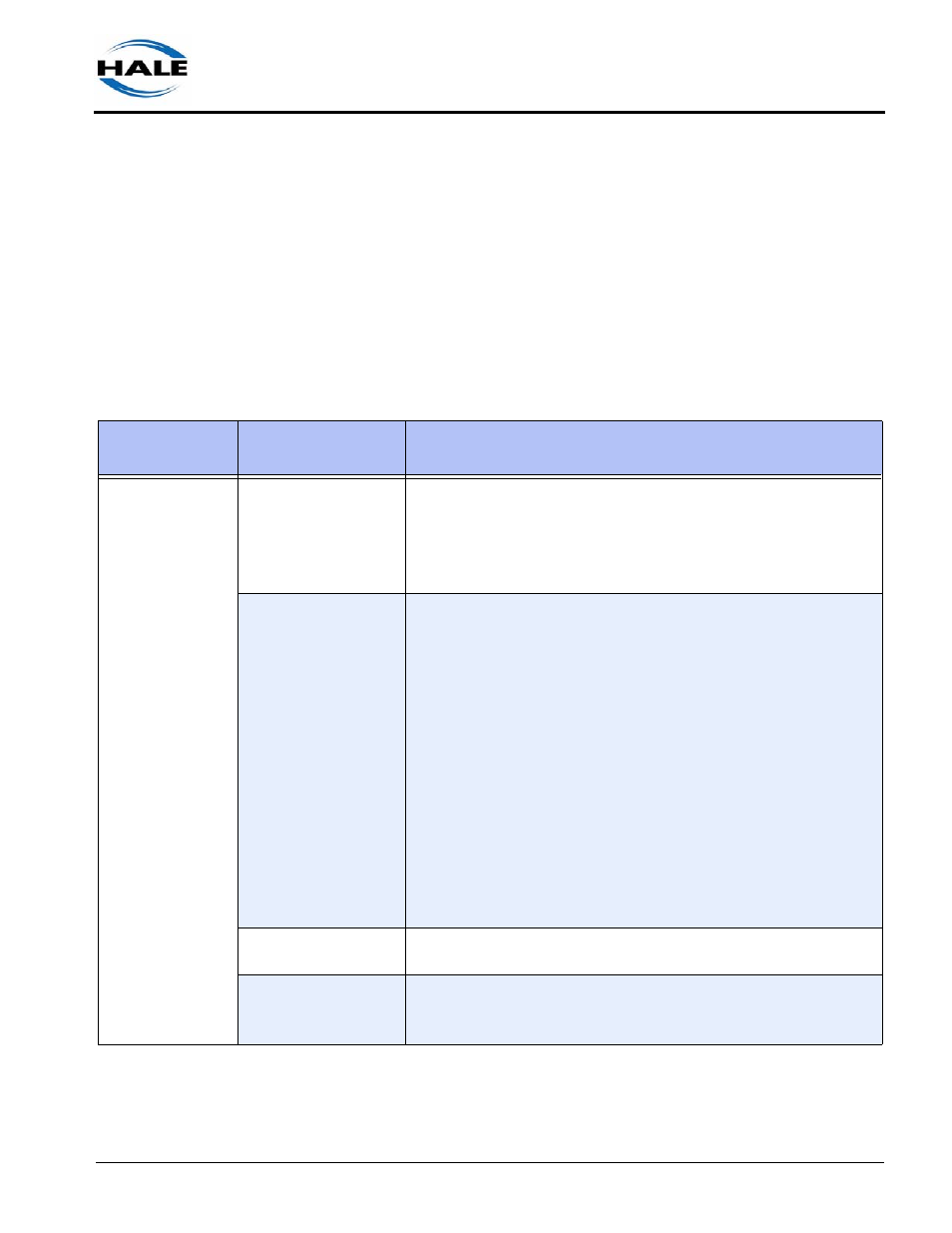

Table 6-1 lists conditions, possible causes and suggested corrective action mea-

sures. Before calling Hale Products or your Hale authorized parts service center

for assistance, eliminate problem causes using the following table.

If you cannot correct a problem, please have the following information prior to call-

ing the Hale Customer Service for assistance. Contact Customer Service at tele-

phone number 610-825-6300. .

Condition

Possible

Cause

Suggested Corrective Action

Pump Loses

Prime or Will Not

Prime.

Chart continued on

next page.

Electric priming sys-

tem.

Note: Weekly priming is

recommended to ensure

proper operation.

• To prevent possible pump damage, DO NOT EXCEED an engine

speed of 1,000rpm!

• See Section 2.2 “SPV Priming Valve” on page 12. Also see “PVG

Inoperative priming

system or possible

clogged priming pump.

Note: Using lubricant on the vanes and vane slots during disassembly

and cleaning eventually causes a gummy residue to develop, rendering

the system inoperative.

DO NOT LUBRICATE VANES AND VANE SLOTS.

• Check the priming system by performing a “Dry Vacuum Test” per

NFPA standards. If the pump holds vacuum, but primer pulls less

than 22” Hg., it could indicate excessive wear in the primmer.

• See Section 5 Maintenance, heading “Weekly” on page 35.

Also see Section 5 Maintenance, heading “Annually” on page

37.

• See Section 2.2 “SPV Priming Valve” on page 12. Also see

“PVG Priming Valve” on page 14.

• Repair and/or replace accordingly.

Note: Using lubricant on the vanes and vane slots during disassembly and

cleaning eventually causes a gummy residue to develop, rendering the sys-

tem inoperative.

Suction lifts too high.

• DO NOT attempt lifts exceeding 22’ (6.7 meters) except at low

elevation.

Blocked or restricted

suction strainer.

• Remove obstruction from suction hose strainer.

• Thoroughly clean strainer screen.

Figure 6-1: Troubleshooting Chart