Table a, Cut rough opening, Insulation barrier installation (optional) – Hired-Hand Baffles, Vents, & Inlets: Vent Kit for Generation Structures User Manual

Page 3: Corner tin, Figure 3

HIRED-HAND MFG., INC.

• 1733 Co Rd 68 • Bremen, Alabama 35033 • Phone 256-287-1000 • Fax 256-287-2000

Manual Part No. 4801-5370 rev 6-04 Page

3 of 8

CUT ROUGH OPENING

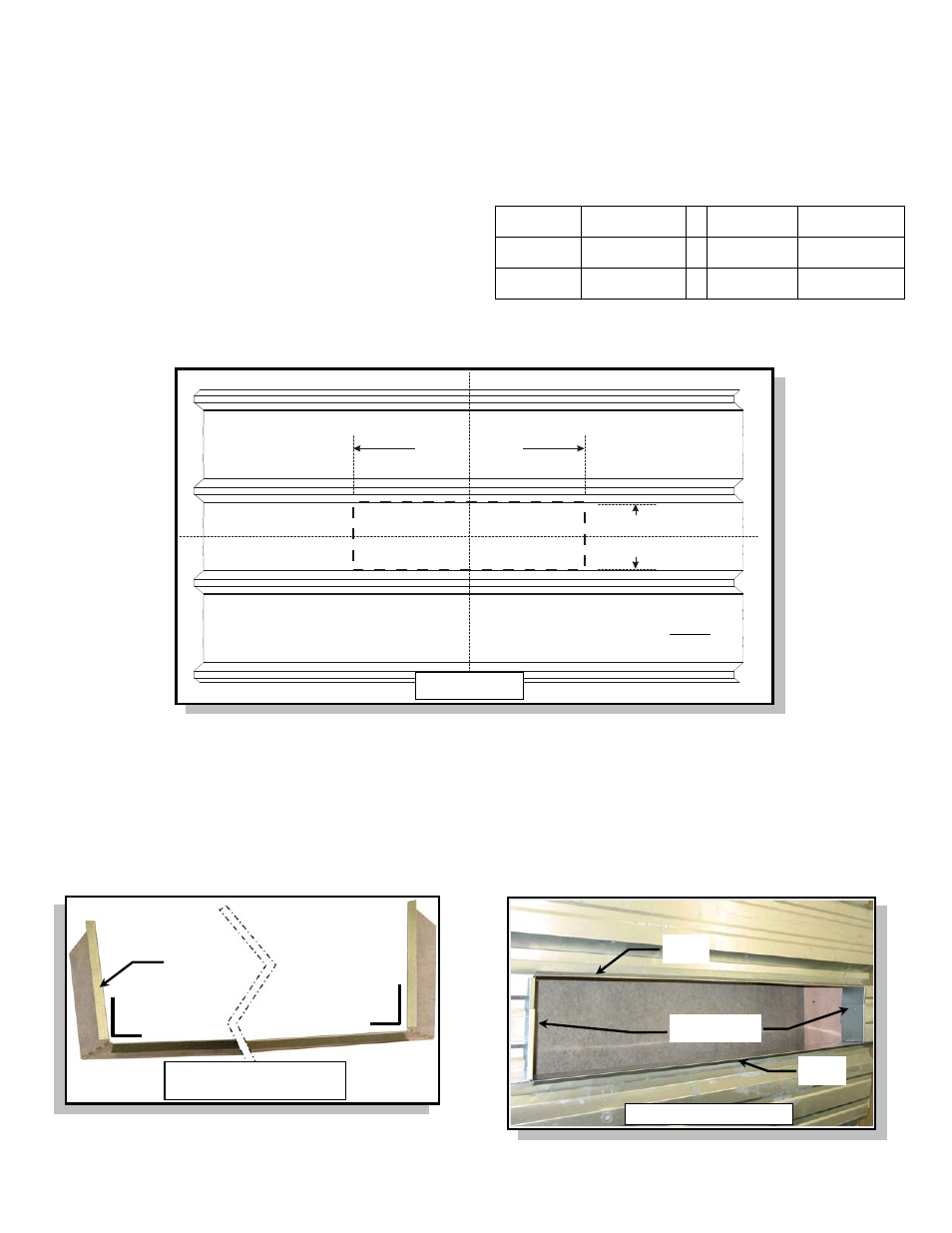

3. Ensure the vent placement is accurate to the

drawings.

4. Refer

to Table A and determine the correct rough

opening size for the required vent kit, determine the

correct rough opening location, and cut a

rectangular hole in the tin.

NOTE: With the corner tin centered on the knee brace,

the flat area of the tin will be the cut-out area.

Always cut the rough opening from the center

section of the tin. Refer to Figure 3.

Vent

Width

“A”

Rough

Opening

Vent

Height

“B”

Rough

Opening

44” 44”

8” 7”

46” 46”

7” 6”

56” 56”

10” 9”

TABLE A

INSULATION BARRIER INSTALLATION

(Optional)

NOTE: If vent duct will be installed, do not install the

optional Insulation Barriers and skip Steps 5 & 6.

5. Bend the two Insulation Barriers as shown in

Figure 4. The flange should always point outward.

6. Insert the two Insulation Barriers (placed in opposite

directions) into the cut-out opening with the barrier

flange overlapping the edge of the cut-out opening.

While keeping the barriers pressed to the cut-out

opening, install #8 x ½” Lap Tek screws through the

barrier overlapping ends. Refer to Figure 5.

INSULATION BARRIER

(Bottom Orientation Shown)

Flange

Outward

FIGURE 4

90°

90°

#8 x ½” Lap Tek

Screws

Top

Barrier

Bottom

Barrier

FIGURE 5

BARRIER INSTALLATION

“A”

Vent Width

Rough Opening

“B”

Vent Height

Rough Opening

C

Corner Tin

NOTE:

Ensure the Rough Opening Height is

centered in the middle of the flat area.

FIGURE 3